Home electrical. Types of nuts, their application and characteristics Nuts with internal and external threads

- ordinary

- high

- low

- self-aligning

- anchor fixed

- floating

- special.

Rice. A.

Rice. b.

Table 1.

| Thread |

M 1 head (largest), N * m |

M 15 holes (smallest), N*m |

| M3 | 0,4/0,7 | 0,03 |

| M4 | 0,7/0,9 | 0,10 |

| M5 | 1,0/1,3 | 0,15 |

| M6 | 1,3/2,7 | 0,20 |

| M8 | 2,0/4,9 | 0,40 |

| M10 | 4,0/6,9 | 0,60 |

| M12 | 9,8/9,8 | 1,00 |

| M14 | 12,7/12,7 | 1,50 |

| M16 | 15,7/15,7 | 2,00 |

Research was carried out on M6 threaded pairs made of Z0KhGSA steel with 4h6h-4H6H and 6e-5H6H threads used in the domestic industry. It is shown that 35 operational bulkheads (tightening the connection with a given torque, holding at 250 °C for 1 hour) withstood all 100% of the self-locking nuts of the 4h6h-4H5H threaded pair and only 50% of the self-locking nuts of the 6e-5H6H threaded pair. The average values of the moments of unscrewing the self-locking nuts of the threaded pair 4h6h-4H5H are 32-80% more than the threaded pair 6e-5H6H. This provides a higher stability of the locking of the threaded connection for fifteen operational bulkheads. For self-locking nuts made of heat-resistant materials, operated under high temperatures, as a rule, reliable locking of threaded connections is limited to five operational bulkheads.

In order to reduce the complexity of installation and assembly work, increase performance characteristics products use self-locking lug nuts, fixed and floating in the cage (fig. D). Fixed lug self-locking nuts are made in double-lug, single-lug and corner versions (Fig. D, a) and are used for fastening hatches, panels, etc.

Rice. D.

The fastening of the nut to the part to be joined is carried out with two rivets. They are made from extract sheet material on multi-position presses or cold wire heading. The locking properties are provided by crimping the bonnet, and sealed deaf ear self-locking nuts - by crimping the threaded part of the cap (Fig. D, b). For sealed compartments, ordinary ear nuts vulcanized with rubber are also used (see Fig. D, b). Self-locking nuts in the holder (Fig. D, c, d) allow compensating for technological errors that are inevitable when assembling large-sized parts of complex configuration. The fastening of the nut on the cage is carried out in grooves or slots that limit its movement and prevent it from falling out of the cage. Depending on the size, the minimum movement of the nut in the cage plane is 0.5-1.0 mm. The options for the execution of the clip are determined, as a rule, by the design of the product. In addition to those considered, self-locking nuts are widely used, floating on a bracket, floating in clothespin clips (Fig. 4, e, f), etc.

Where nuts are used

Under different operating conditions, as well as with different values and types of loads perceived by the connection, the following nuts are used:

- ordinary

- high

- low

- slotted for locking connections

- self-locking of various designs

- self-aligning

- anchor fixed

- floating

- special.

Rice. A. Nuts used in mechanical engineering

High nuts (height is 0.8d) are used for connections that work in tension and perceive large alternating loads. Often for such connections, "reinforced" nuts are used, having a height equal to 1.2d. This significantly increases the creep of the joint, eliminates the destruction of the joints along the shear of the turns of the threaded pair of bolt - nut, this makes full use of the strength of the bolt when working in tension.

High nuts from a diameter of 12 mm or more, in order to reduce the weight of structures, are made with a cylindrical hexagon groove having a size approximately equal to the turnkey size.

Low nuts are used in connections that take small tensile loads, as well as in shear connections.

Slotted hex nuts are used in critical joints operating under vibration loads. Stopping them on the bolt is carried out: cotter pins or wire. For the same purposes, hex nuts are often used with a bolt that is rolled onto the bolt (Fig. A, a).

For decorative purposes, blind hex nuts are used. Deaf nuts for pressing are used in detachable connections, where mounting approaches to the nut are difficult. Round spherical nuts are used as decorative and to eliminate bending loads on the bolt in the connection. A wing nut is used for quick couplings, as well as in swing bolts, etc. (Fig. A, b).

Round nuts with internal and external threads, with slots at the end and around the perimeter are widely used in connections with a diameter of 14 mm or more. The smaller mass and dimensions of round nuts compared to hexagonal nuts can significantly reduce the weight of structures as a whole. Round nuts with internal thread and slots on the end (usually 2 slots) are widely used and small diameters, starting from 1.4 mm, providing the same advantages of connections (Fig. A, c).

To prevent self-loosening of threaded connections during operation, in most cases their locking is required. However, the weighting of structures, the low reliability of locking, the high labor intensity of manufacturing and installation and assembly work to perform locking of threaded pairs led to the creation and widespread introduction of self-locking nuts in all branches of mechanical engineering. The basis of locking with self-locking nuts is the creation of a guaranteed tightness and an increase in friction in a threaded pair due to deformation of the threaded part of the nut or the use of threadless elastic inserts.

A typical self-locking nut is a conventional hexagonal or other nut with a thin-walled threaded cylindrical section on a non-supporting end - a boncoy. The bonk has longitudinal slots (4-6), which are deformed around the perimeter by a conical mandrel to create an interference fit in the threaded pair (i.e., the locking properties of the nut). Such nuts are called self-locking slotted nuts (Fig. A, d, e). Depending on the operating conditions, the following self-locking slotted nuts are used: high and low hexagonal nuts, twelve-sided, round knurled for pressing, if the design of the assembly allows for an increase in the hole in the part to be connected, and the approach for installing the nut is difficult.

Now, due to the high labor intensity of milling slots, slotted self-locking nuts, especially of sizes M3-M10, are practically replaced by more technologically advanced, but not inferior to them in terms of locking reliability, self-locking nuts with a continuous deformed bolt (Fig. A, e, f). Self-locking nuts with a continuous bolt are also used high and low, for pressing, twelve-sided, with a groove configuration, etc. The scope of high and low self-locking nuts, twelve-sided and with a groove configuration is determined by the same operating conditions as conventional nuts.

In connections that work primarily in shear, hex self-locking nuts without a bolt, with a support shoulder and a reduced size of the turnkey hexagon (thin-walled hexagon) are widely used. Self-locking of such nuts is achieved by directly deforming the hexagon (see Fig. A, e). In the conditions of automated assembly of threaded connections, self-locking nuts with a washer rolled onto the support collar are used.

Rice. b. Self-locking sealed nuts with fluoroplastic (a) and with a nylon insert (b)

A sealed self-locking nut is shown in fig. B, a. The sealing insert based on PTFE is mounted in the bore of the nut with an interference fit and protrudes 0.5-0.8 mm above the end face. When assembling the connection, the conical transition from the thread to the smooth part of the bolt fits tightly with an interference fit inside the liner, sealing the thread along the inner and outer diameters of the liner. The part protruding from the nut, when tightened, seals the connection along the joint plane. Stopping is provided by compression of a nut on a dodecahedron.

A self-locking hex nut with a resilient nylon insert is shown in fig. B, b. A nylon insert is rolled into the top of the nut. The inner diameter of the bushing is approximately equal to the inner diameter of the bolt thread. The thread in the insert is formed by the bolt when it is screwed in, providing the necessary tightness to lock the threaded pair. Nuts with nylon insert can be round, dodecahedral, lug, etc.

Rice. WITH. Types of crimping of self-locking nuts

In the Russian industry, obtaining a locking element of self-locking nuts is carried out by crimping the bolt at a given value at two points, at two points along an ellipse or at three points parallel to the axis or at an angle of 12-16 °. It is possible to obtain a locking element with a draft of a boom (Fig. C). Nut thread accuracy 5N6N.

Self-locking nuts remain functional after repeated reassembly of threaded connections. The maximum moment of the first tightening of the nut and the minimum moment of the fifteenth unscrewing (M1zav and M15otv) are normalized. In the domestic industry, they correspond to the values \u200b\u200bspecified in Table. 1. ISO standards for the fifteenth unscrewing torque are higher due to the use of precise threads: for bolts 4h6h, for nuts 4H5H.

Table 1.

Standards for locking properties of self-locking nuts

| Thread |

M 1 head (largest), N * m |

M 15 holes (smallest), N*m |

| M3 | 0,4/0,7 | 0,03 |

| M4 | 0,7/0,9 | 0,10 |

| M5 | 1,0/1,3 | 0,15 |

| M6 | 1,3/2,7 | 0,20 |

| M8 | 2,0/4,9 | 0,40 |

| M10 | 4,0/6,9 | 0,60 |

| M12 | 9,8/9,8 | 1,00 |

| M14 | 12,7/12,7 | 1,50 |

| M16 | 15,7/15,7 | 2,00 |

Note. In the numerator - for lug and floating nuts; in the denominator - for hex nuts.

Research was carried out on M6 threaded pairs made of Z0KhGSA steel with 4h6h-4H6H and 6e-5H6H threads used in the domestic industry. It is shown that 35 operational bulkheads (tightening the connection with a given torque, holding at 250 °C for 1 hour) withstood all 100% of the self-locking nuts of the 4h6h-4H5H threaded pair and only 50% of the self-locking nuts of the 6e-5H6H threaded pair. The average values of the moments of unscrewing the self-locking nuts of the threaded pair 4h6h-4H5H are 32-80% more than the threaded pair 6e-5H6H. This provides a higher stability of the locking of the threaded connection for fifteen operational bulkheads. For self-locking nuts made of heat-resistant materials operating at high temperatures, as a rule, reliable locking of threaded connections is limited to five operational bulkheads.

The final quality control of self-locking nuts is to measure the tightening and loosening torques. This allowed foreign firms, when standardizing self-locking nuts within the framework of ISO, not to specify in the design documentation the outer diameter of the bolt, the height, size and shape of the crimped, leaving these issues at the discretion of the manufacturer.

In order to reduce the complexity of installation and assembly work, to improve the performance of the product, self-locking eye nuts are used, fixed and floating in the holder (Fig. D). Fixed lug self-locking nuts are made in two-lug, one-lug and corner designs (Fig. D, a) and are used for fastening hatches and panels.

Rice. D. Self-locking lug nuts, fixed and floating

The fastening of the nut to the part to be joined is carried out with two rivets. They are made by drawing from sheet material on multi-position presses or by cold heading from wire. The locking properties are provided by crimping the bonnet, and sealed deaf ear self-locking nuts - by crimping the threaded part of the cap (Fig. D, b). For sealed compartments, ordinary ear nuts vulcanized with rubber are also used (see Fig. D, b). Self-locking nuts in the holder (Fig. D, c, d) allow compensating for technological errors that are inevitable when assembling large-sized parts of complex configuration. The fastening of the nut on the cage is carried out in grooves or slots that limit its movement and prevent it from falling out of the cage. Depending on the size, the minimum movement of the nut in the cage plane is 0.5-1.0 mm. The options for the execution of the clip are determined, as a rule, by the design of the product. In addition to those considered, self-locking nuts are widely used, floating on a bracket, floating in clips, clothespins (Fig. 4), etc.

In some industries, profiles with self-locking floating nuts are widely used (Fig. E). Extruded profiles are made from aluminum alloys, bent profiles- from a steel sheet. Fixing the position of the nuts on the profile is carried out by local stampings (see Fig. E, a) or tabs bent along the notches (see Fig. E, b).

Rice. E. Profiles with self-locking floating nuts

The length of the profile with self-locking floating nuts is determined by the design of the product, and it can reach 1.5 m. The profile is fastened to the part to be joined with rivets in increments of 150-250 mm. The use of profiles with self-locking floating nuts allows to reduce the weight of the structure, as well as increase the strength of the connection. Strength is increased by reducing the number of rivet holes in the parts to be joined.

Select a category: All Anchors » Wedge anchor » anchor bolt» Double spacer anchor » Ring anchor » Hook anchor » Anchor bolt with nut » Countersunk head anchor bolt » Hook anchor bolt » Ring anchor » Ceiling anchor » Wedge anchor » Folding spring dowel with hook » Drop anchor » Expansion anchor » Metal anchor frame dowel» Metal dowel for hollow structures Nail » Construction nails (black) » Galvanized nails » Screw nails » Spiked nails » Finishing nails » Roofing nails » Slate nails » Colored nails » Nails for stapler Self-tapping screws » Self-tapping screws for wood yellow zinc » Self-tapping screws for drywall » Wood screws » Press washer screws » Window screws » Screws for window profiles» Self-tapping screws for GVL » Self-tapping screws for profiles » Self-tapping screws with a drill » Screws for concrete (Nagel) » Roofing screws »» Galvanized roofing screws »» Painted roofing self-tapping screws » Self-tapping screws for sandwich panels » Self-tapping screws for hardwoods » Universal self-tapping screws » Spax self-tapping screws » Self-tapping screws for parquet and massive board» Capercaillie screw » Ring screw » Half ring screw » Crutch screw » Fastening for scaffolding» Structural screws »» Structural wood screws with countersunk head »» Structural wood screws with hexagon head »» Structural wood screws with press washer »» Screws for parquet and solid board Perforated fasteners» Perforated mounting tape » Connection plate » Mounting plate » Window plates » Sliding mounting bracket » Anchor mounting bracket » Equilateral mounting bracket KUR » Perforated bracket » Asymmetric mounting bracket » Reinforced mounting bracket » 135 degree mounting bracket » Z-shaped mounting bracket » Corner connector » T-shaped connector » Beam holder » Beam support » Beam support closed » Beam support open » Anchor adjustable in height » Fasteners for kitchen » Tape for underfloor heating » Profile connector (Crab) » Knauf direct suspension » Sliding rafter support » Mounting profile » Beacon profile » Corner protection profile » Nail plate » Beam angle » Wide angle » Narrow angle » Frame angle » Double force angle » Adjustable angle » Support bracket » Mounting traverse » Washer with threaded sleeve » Fasteners for racks Dowel - nail » Hammerable metal dowel-nail » Wkret-met dowel » Omax dowel » Tech-Krep dowel 580 » Ring nut DIN 582 » Rope clamp »» Cable clamp steel ropes DIN 741 »» Clamp for steel ropes Duplex »» Clamp for steel ropes Simplex »» Clamp for steel ropes Flat » Tie » Carabiners »» Fire carabiner DIN 5299C »» Screw carabiner »» Carabiner with lock DIN 5299D » Shackle » S- shaped hook » Short-link welded chain » Long-link welded chain » Steel cable » PVC-sheathed cable Dowels » Metal dowel for aerated concrete » Drywall dowel "Driva" » Rondole washer » Butterfly dowel for drywall » Expansion dowel » Hedgehog dowel » Multifunctional dowel » Three-lobed dowel » Foam concrete dowel » Multifunctional dowel » Long dowel » Facade dowel KPR » Dowel for fastening thermal insulation » Mounting dowel » Plugs for nails » Expansion dowel KPX Bolts Nuts Washers » Threaded stud DIN 975 » Bolts with partial thread » Bolts with full thread » Bolts with internal hexagon » Zinc-plated nut » Connecting nut (Coupling) » Wing nut » Cap nut » Self-locking nut » Nut with flange » Mustache nut » Reinforced washer DIN 9021 » Washer with rubber gasket » Regular washer » Grover washer Furniture fasteners» Furniture mounting bracket » Furniture bracket (White, Brown) » Domestic furniture bolts » Furniture bolt » Confirmat screw Clamps for Hawera fittings » SDS-Plus drills for concrete » Segment drills with adapter » Drills for concrete "Perfect power" » Drills for metal "Hss-r" » Concrete drills "Multiconst" » Wood drills "Perfect" » Peaks "SDS - Plus" » Chisels "SDS - Plus" » Jigsaw blades Nozzles Staple guns and staples Construction staple Jute rope Mezhventsovy heater Linen Plumbing fasteners » Plumbing hairpin » Plumbing collar Blind rivet Riveters » Riveters » Blind rivet Mounting chucks Tolerance button Welding electrodes Dowels Cutting wheels Kleimers for lining Work gloves Foam and sealants Towels Rags Bags for construction waste Consumables for grinders Drills for drills Crosses and wedges for tiles Measuring tapes Painting knives Blades Wall brackets BIT chemical anchors Stainless steel fasteners » AISI 304 stainless steel cable section 7x7 » AISI 304 stainless steel cable section 7x19 » DIN 741 stainless steel cable clamp AISI 304 » DIN 52 simplex stainless steel cable clamp 99 AISI 304 » Stainless steel thimble AISI 304 » Stainless steel clamp S.HC01 » Stainless steel chain (short link) DIN 5685 AISI 304 » Stainless steel chain (long link) DIN 5685 AISI 304 » Stainless steel lanyard (hook-ring) DIN 1480 AISI 304 » Stainless steel block for cable S.BL03 AISI 304 » AISI 304 stainless steel rotating hook. S.HK05 » AISI 304 stainless steel self-tapping screw with ring ART-9079 stainless steel AISI 304 DIN 933 » AISI 304 Stainless Steel Wing Nut DIN 315 » AISI 304 Stainless Steel Threaded Stud DIN 975 » AISI 304 Stainless Steel Cap Nut DIN 1587 » AISI 304 Stainless Steel Nut DIN 934 » Stainless Steel Reinforced Washer ki AISI 304 DIN 9021 » Eye AISI 304 stainless steel nut DIN 582 » AISI 304 stainless steel eyebolt DIN 580 » AISI 304 stainless steel eyebolt S.EB09-06 » AISI 304 stainless steel fire carbine DIN 5299C » AISI 304 stainless steel fire carbine DIN 5299D » Carbine With a stainless steel of AISI 304 S.SN02 stainless steel, a carabiner with AISI 304 S.Sn08 stainless steel with a stainless steel of AISI 304 S.SW02-05 stainless steel izi bolt AISI 304 »Bolts with incomplete stainless steel AISI 304 DIN 931 » AISI 304 Stainless Steel Screws » AISI 304 Stainless Steel Coupling WS 9290 » AISI 304 Stainless Steel Washer

On fig. 143 showing the main types of hex nuts: with a one-sided chamfer with a diameter D 1 \u003d S (Fig. 143, I); with a one-sided chamfer with a diameter of D 1 \u003d 0.95 S (Fig. 143, II); with a double-sided chamfer (Fig. 143, III); with an annular sharpening on the support end (Fig. 143, IV); with a collar on the support end (Fig. 143, V).

On fig. 144 and 145 are nuts various types; slotted (Fig. 144, I); crowned (Fig. 144, II); slotted with a shortened hexagon (Fig. 144, III); with a conical crown (Fig. 144, IV); with shortened hexagons (Fig. 145, I); with a lead-in cone for a socket wrench (Fig. 145, II); with conical and spherical bearing surfaces (Fig. 145, III, IV).

Depending on the purpose, the nuts may have different height from 0.3d to 1.25d (d is the thread diameter). Low nuts are used as locknuts and for lightly loaded connections, high nuts are used for heavily loaded connections, as well as for frequently disassembled connections. For medium operating conditions, nuts with a height of (0.8-1) d are used. With these ratios, the condition of equal strength of the nut and the threaded rod is approximately observed.

On fig. 146-153 nuts are shown with different forms wrapped elements; in fig. 154 - nuts with internal screwed elements (hexagon, slots), used in cases where power tightening is required with limited radial dimensions; in fig. 155 - cap nuts used in cases where it is required to ensure the tightness of the threaded connection; in fig. 156, 157 nuts with an external thread are presented.

slotted nuts. The design of a cylindrical nut with small triangular slots along the generatrix (Fig. 158) is progressive.

In the future, such nuts may possibly replace hex nuts. Their main advantage lies in a more favorable distribution of forces when tightening the nut. From fig. 159 it can be seen that the shoulder of forces acting when tightening on a slot of a triangular profile with an angle at the top of 60 ° is approximately 2 times greater than in the case of tightening a hex nut.

The number of splines on the nut circumference can be 6-7 times the number of hexagon faces. Consequently, with the same tightening torque, the force per each spline will be 12–15 times less than the force acting on the face of the hex nut when tightened with a tubular wrench, and 36–45 times less than when tightened with a spanner wrench. The danger of crushing the tightening surfaces, so real with hex nuts, this case excluded. Thanks to the shape of the screw-in elements, the risk of the wrench being torn off during tightening is also eliminated.

Another advantage is that the nut can be turned to almost any angle when tightened, making it easier to tighten in tight spaces where span is limited.

Slotted nuts with the same thread diameter have smaller radial dimensions and less weight than hex nuts. The disadvantage of slotted nuts is that they can only be tightened with a tubular wrench.

When designing fasteners with slotted nuts, free space should be provided above the nut for putting on a tubular wrench. The height of this space when turning with an open tubular wrench can be reduced by reducing the thickness of the wrench. Reducing the height of the slots (Fig. 160, I-III) facilitates the manipulation of the key: when removing and re-putting on the key, the key is centered by the cylindrical part of the nut. It is also possible to use special keys with adjustable jaws, allowing access to the nut from the side.

The margin of crushing strength of spline nuts (Fig. 161, I) is so large that it is possible to reduce the number of splines without much damage to reliability (Fig. 161, II-IV). The mass of the nut is thus reduced; advantages when tightening a nut are fully preserved if the slots on the key are cut around the entire perimeter.

1) the diameter of the nut along the recesses of the splines D1 = (1.35–1.50)d where d is the nominal thread diameter; the upper limit (1.5) applies to small nuts, the lower limit to medium and large;

2) the outer diameter of the nut along the protrusions of the slots D = (1.10-1.15) D 1; here the upper limit also applies to small nuts, the lower limit to medium and large ones;

3) nut height H = (0.8-1.0)d.

Slotted nuts (Fig. 160) are most often locked with cotter pins.

ring nuts. Ring nuts are used for tightening shaft fittings, rolling bearings and similar parts on shafts. large diameter.

This type of nuts includes nuts, called according to GOST 11871-80 round slotted.

A feature of ring nuts is a relatively small height with a large diameter. Due to the large diameter of the thread, a nut of ordinary height is excessively strong and very heavy.

It is easy to determine the height of the nut required by the condition of equal strength of the nut and the shaft (for the case of a hollow shaft).

The condition of equal strength of a hollow shaft working in tension from the action of the tightening force, and a threaded belt working in shear from the action of the same force, has the following form:

where [τ] is the allowable shear stress in the thread; [σ r ] - allowable tensile stress of the shaft; H is the length of the working thread belt (height of the nut); D c p and D 0 - respectively average diameter threads and bore diameter in the shaft.

For average conditions, taking into account the stress concentration in the threads, it can be assumed that the allowable shear stress in the thread is 2 times less than the allowable tensile stress for the shaft. Then

From this expression it can be seen that the height of the nut decreases with an increase in the diameter of the shaft hole (Fig. 163).

When standardizing ring nuts, it is difficult to take into account the factor D 0 /D cp; usually the height of the nuts is set only depending on the diameter D of the thread. In this case, the height H of the nuts (Fig. 164) is approximately (0.15-0.25) D (smaller values refer to nuts of large diameter, and large ones to smaller diameters).

Due to the low height of the ring nuts, only fine pitch threads are used in them. The use of large threads (Fig. 165, I) would lead to a decrease in the total number of threads on the nut with a decrease in strength (due to the relative decrease in the number of threads with a full profile), would worsen the axial direction of the nut along the shaft and, in addition, would weaken the shaft due to for reducing the inner diameter of the thread.

Thread pitch s for ring nuts is usually taken approximately equal to (0.015-0.050) D, where D is the thread diameter; the upper limit refers to threads of small diameter (20-50 mm), the lower limit - to threads of large diameter (100-120 mm). When designing ring nuts, it is recommended that the thread pitch (and nut height) be chosen so that total number there were at least 5-6 threads on the nut (Fig. 165, II).

As in all threaded connections, thread stocks should be provided on both sides of the nominal position of the nut. Recommended reserves are shown in fig. 166.

The size of the nut in the recesses of the splines, which determines minimum thickness the working ring of the nut, perform equal to S = (1.2-1.3) D. The outer diameter of the nut D 2 varies within ~ (1.4-1.5) D (Fig. 164).

The sections of the nut on which the grooves are located should not protrude onto the supporting surface of the end face of the nut, since when the side faces of the grooves are crushed during tightening or unscrewing, the nut will not fit snugly against the part being tightened. For this, grooves or chamfers are made, one-sided or (better) two-sided (Fig. 167). The outer diameter D 1 of the bearing surface must be smaller size S between the cavities of the grooves is at least 0.5-1 mm.

On fig. 168 shows ring nuts with internal threads and with various arrangements of screwed grooves; in fig. 169-177 - nuts with screwed elements of other types.

Most often, nuts with external grooves are used, the number of which varies between 4-12. Such nuts are wrapped with cap "open-end" wrenches (Fig. 178, I) or wrenches with end (Fig. 178, II) or internal radial (Fig. 178, III) teeth.

The number and shape of the grooves and protrusions of the nut significantly affect its mass. In machines where the requirement to reduce weight is at the forefront and where a large number of ring nuts are used, considerable attention is paid to the design of the grooves.

On fig. 179 shows the relative masses of slotted nuts various designs. The mass of a nut with four grooves is taken as a unit. As can be seen from fig. 179, I-IV, a simple increase in the number of grooves can significantly reduce the mass. The mass of a nut with twelve grooves (Fig. 179, IV) is 86% of the mass of a nut with four grooves (Fig. 179, I). A further reduction in mass is achieved by sampling non-working sections of the protrusions between the grooves (Fig. 179, V), reducing the height and width of the protrusions (Fig. 179, VI) and reducing their number (Fig. 179, VIII).

The most advantageous design (Fig. 179, IX) with a small number of protrusions of a triangular profile; the mass of the nut is 53% of the mass of the original nut. The groove profiles shown in Fig. 179, V-IX, can be obtained by a high-performance rolling method using a worm profile cutter.

Nuts, the design of which is shown in fig. 179, VI-IX, are wrapped only with tubular keys.

When tightening fittings with ring nuts, it is necessary that the end of the nut rests on the part by at least 3/4 of its height (dimension S in Fig. 180, I). If the height of the step on the shaft does not allow this condition to be met, a massive washer is installed between the nut and the part (Fig. 180, II).

It is important that the washer is centered. On fig. 181, I shows an incorrect installation: the washer can move into the undercut behind the thread. On fig. 181, II-IV shows the methods of centering the washer, of which the simplest is the method of centering on the outer diameter of the thread (Fig. 181, II).

In cases where uniform pressure is required on the tightened part, spherical washers are used (Fig. 182). Other ways to solve this problem are to maintain strict perpendicularity between the end of the nut and the average diameter of the thread or to use threads with axial and radial clearances on the turns, which allow the nut to self-align on the shaft.

Rice. 178. Wrenches

![]()

Rice. 179. Relative mass of ring nuts with screwed elements various shapes

The groove profiles shown in Fig. 179, K-/X, can be obtained by a high-performance rolling method using a worm profile cutter.

Nuts, the design of which is shown in fig. 179, K / - / X, wrap only with tubular keys.

When tightening fittings with ring nuts, it is necessary that the end of the nut rests in the part at least 4 times its height (dimension S in Fig. 180, /). If the height of the step on the shaft does not allow this condition to be met.

Rice. 180. Installing a ring nut without a washer (U) and with a washer ()

a massive washer is installed between the nut and the part (Fig. 180,).

It is important that the washer is centered. On fig. 181,/ shows an incorrect installation: the washer can move into the undercut behind the thread. On fig. 181, - / V shows the methods of centering the washer, of which the most simple is the method of centering on the outer diameter of the thread (Fig. 181,).

In cases where uniform pressure is required on the tightened part, spherical washers are used (Fig. 182). Other ways to solve this problem are to maintain a strict perpendicularity between the end of the nut and the average diameter of the thread, or to use threads with axial and radial clearances in the turns, which allow the nut to somewhat self-align on the va.pu.

On fig. 183 -188 shows the designs of round nuts with external threads, of various shapes and with various elements for screwing.

Rice. 181. Centering under- [t;

clad washers: / - without centering; lino thread outer diameter; III - along the shoulder of the gunk; IV - according to nasadion details

Rns. 182. Spherical washers

Rice. 183. Ring nuts with external thread with internal grooves

Rice. 184. Ring nuts with external thread and external grooves

Rice. 185. Ring nut with external thread and face grooves

Rice. 186. Ring nuts with external thread, triangular slots and ribs

Rice. 187. Ring nuts with external thread and Rns. 188. Ring nuts with external thread axial holes iodine wrench with internal hexagon

Rice. 189. "Non-burning" nuts. Fixation methods

SOME TYPES OF FASTENERS

"Heatproof" nuts and "captive" bolts

In some cases, after unscrewing the nut and several threads, it is desirable to fix it in order to prevent the nut from completely wrapping off the threaded end of the bolt. it is required to loosen the nut one or two turns in order, for example, to regulate the position of one part relative to another, etc.

On fig. 189, / and shows the methods of fixing by riveting or punching the ends of the bolts, and in fig. 189, / - by riveting the restrictive washer. If the design allows the nut to be screwed from the opposite end of the threaded rod, then a smooth cylindrical belt is left with the side wrapped (Fig. 189, IV).

Of the fixation methods shown in Fig. 189, K-VIII, the simplest and most reliable method is fixation with a zeger - a locking ring (Fig. 189, V /). In the design in Fig. 189, V / at the end of the bolt is made

undercut with a height equal to the height of the threaded section of the nut. When screwing, the nut falls into the recess; threaded belt at the end of the bolt to a certain extent protects against complete screwing of the nut.

On fig. 190 gives an example of the use of "non-losing" nuts for fastening the cover ia

Rice. 190. "Non-burning" nuts. The case of fastening the cover to the body

Read also...

- Provisional government in Russia What did the Bolsheviks do with the provisional government

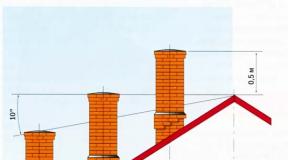

- The height and diameter of the chimney for solid fuel boilers Calculation of the chimney from the boiler in a private house

- How to properly make a roof vapor barrier: technological principles of a vapor barrier device

- Chimney for a gas boiler: device features and requirements for gas boilers What pipe diameter is needed for a gas boiler