DIY stainless steel crafts. Stainless steel smokehouse at home Hot and cold forging

A stainless steel smokehouse is an assistant for lovers of homemade smoked meats. Her easy to do with your own hands, if you know in detail the manufacturing process of the device.

Wherein self-production smokehouses has a lot of advantages: the ability to choose any design, which is limited only by the author’s imagination, the use of high-quality materials, saving money.

Types of household smokehouses with a stainless steel water seal

Stainless steel smokehouses have a lot of advantages: a light weight, durability, tightness, easy to carry. Such structures are made from sheet metal — of stainless steel. In order to prepare stainless steel for use, you need to carefully clean it from dirt and dust. If there are dents on thin canvases, they are smoothed out with a hammer.

Photo 1. Homemade smokehouse, made of stainless steel. The build quality is no worse than its factory counterparts.

Most owners of factory stainless steel smokehouses are dissatisfied with the main drawback of the devices - thin metal thickness. The miniature size of these products, as well as the thin-walled grilles, are also depressing.

A self-made smokehouse lacks all this. The master has complete freedom to choose both materials and design modifications. But the principles of smokehouse design when creating them must be complied with.

Any apparatus for preparing smoked products consists of several main parts:

- smoking chamber;

- fireboxes;

- chimney.

Among the minor elements— doors, control devices, equipment for stacking and hanging products (grids and hooks). A stainless steel smokehouse can be equipped with a water seal, which is otherwise called a water lock.

Task water seal- prevent the penetration of air into the smoking chamber and prevent the escape of smoke with an odor from it. In the first case, the issue of sawdust combustion is resolved, and in the second, the comfort of cooking smoked meats at home is ensured.

A stainless steel smokehouse is always lightweight and portable. She consists of several elements:

- from a sealed metal box with handles (medium sizes 500x300x300 mm);

- from flat, triangular or semi-oval lids with soldered hollow tube for smoke removal;

- from pallet with short legs(designed to accumulate fat dripping from food);

- from two gratings, located in two tiers;

- can be built into the lid thermometer.

A firebox and chimney are not provided for this type of smokehouse. Works on the principle of hot smoking. Sawdust and smoking shavings are placed directly to the bottom of the chamber. Smoke is discharged through a hole in the lid. If the process of preparing goodies takes place at home, they put a hose of the appropriate diameter and take it outside the apartment, for example, through a window.

Making a smokehouse with your own hands from stainless steel. steel 2 and 3 mm thick. Blueprints

Offered detailed instructions for making a stainless steel smokehouse 2 mm thick with parameters:

- height 280 mm;

- length 520 mm;

- width 310 mm.

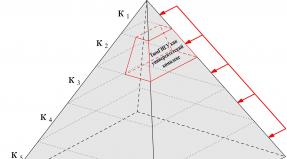

Photo 2. Drawing of a stainless steel smokehouse. View in cutting, side and top. You can choose any size of the device.

To work you will need the following materials and tools:

- stainless steel thickness 2 mm;

- metal corner 15x15 mm;

- metal rods with a cross section of at least 2 mm;

- roulette;

- simple pencil;

- square;

- angle grinder (grinder);

- thick metal disc 1—1.5 mm;

- metal tube cross-section 8-10 mm and length 2.5-3 cm;

- wooden block any section, length not less 520 mm.

Photo 3. Drawing of all parts (box, tray, grate) of a stainless steel smokehouse indicating the dimensions of the structure.

All elements of the device are manufactured from the same material. But the handles for the camera and lid can be made from anything non-flammable. These can be fireproof handles from pots or other kitchen utensils.

Project selection

A stainless steel smokehouse can be any geometric shape : square, rectangular, round. The second form is universal. Suitable for both home and hiking conditions.

Round design chosen if it is necessary to prepare a large number of products in one smoking session. Such devices are in many ways similar to massive tanks. They are difficult to move, so it is recommended to determine a permanent location for the device.

In order to make the task of making a smokehouse easier for yourself, you need to do drawing of the future device. School knowledge of geometry and mathematics will help with this. Universal stainless steel smokehouses consist of many rectangles different sizes. Need to determine length, height and width the main element is the smoking chamber. After this, it will not be difficult to make a drawing of the lid, grates and tray.

You might also be interested in:

How to choose materials

Factory smokehouses are made of thick stainless steel 1.5 mm(chamber and cover) and 0.8 mm(grids and tray).

Practice has shown that this material has a number of disadvantages: when heated, the metal bends, and the grates also bend under the weight of the food.

Therefore, for making homemade apparatus It is recommended to choose metal thickness from 2 mm.

If you plan to create a stationary large smokehouse, you will need metal thick not less than 3 mm.

Reference. Best choice will be food grade stainless steel AISI 304 or its equivalent 08Х18Н10.

Steel thickness AISI 304 from 0.8 to 50 mm. The surface of these metal sheets There are 3 types:

- mirror;

- semi-mirror (polished);

- matte.

Case manufacturing

Step 1. Using a grinder or metal scissors, cut out a strip of steel length 166 cm and height 280 mm.

Step 2. Mark the places where the fabric folds will be made:

- measure out 520 mm, draw a vertical line;

- measure from this line 310 mm and draw a vertical line;

- measure again 520 mm.

Step 3. Take a grinder with a metal disc and make cuts with a depth of no more than 1 mm strictly along the previously drawn lines.

Step 4. Bend a strip of metal in the places where the cuts are made. For greater convenience, use a wooden block, the length of which exceeds the width of the metal sheet. The end result should be a hollow box.

Step 5. Weld the two sides of the box to each other. Clean and level the weld seam.

Step 6 A rectangle of size is cut from a stainless steel sheet 540x330 mm. This is how you get a bottom, on each side of which there will be a bend on 1 cm towards the smoking chamber.

Step 7. On this canvas, draw 4 lines along the perimeter of the rectangle, departing from its edges along 1 cm.

Step 8 By analogy with the construction of the box, cuts are made and the edges of the bottom are bent.

Step 9 Insert the box into the bottom and boil around the perimeter. Check the quality of the weld by pouring water into the resulting container.

Step 10 They make a water seal by welding a corner around the perimeter of the box 15x15 mm.

The end of the vertical shelf of the corner should not be at the same level with the upper plane of the box, but below it by 3-5 mm. This is necessary so that if the water seal overflows, water does not enter the smoking chamber.

Step 11 Cut from steel sheet rectangle size 542x332 mm and make a smokehouse lid. The handles are welded to it or secured with bolts.

Step 12 A hole is drilled in the lid with a cross-section 8-10 mm. Weld a metal tube length to it 2.5-3 cm.

Smokehouse base

The base of the smokehouse is its legs. They can be made from metal corners or segments fittings. The selected material is cut into parts of the required length using a grinder and welded using welding machine and electrodes.

What to weld the grate from

From metal rods weld the grate. The legs and top pins of the grille are also made from them. A metal tube will be placed on these protrusions, into which the second tier grille is inserted from above.

The second lattice is made in a similar way. It should not have pins at the top.

When performing such a technological operation as welding stainless steel, it is important to consider how physical properties material and its chemical composition. Only in this case can you count on the connection being made efficiently and reliably.

Difficulty factors for welding stainless steel parts

What makes welding stainless steel difficult is that this material belongs to the category of high-alloy alloys, which means that its composition contains quite large quantities contains elements that influence its basic properties. In stainless steel, in particular, this element is chromium. Its content in this alloy can be 12–30%. Chromium, along with elements such as nickel, titanium, manganese and molybdenum, forms anti-corrosion properties, but at the same time gives it other features that affect weldability.

For those who do not like to read long articles and delve into technical details, we suggest you immediately watch two videos with the most relevant ones. home handyman options for welding stainless steel - with an electrode using an inverter and again with an inverter, but in a protective gas environment (argon).

Welding of stainless steel must be carried out taking into account the following specific characteristics this material.Sufficiently high coefficient of linear expansion

For this reason, welding stainless steel is always accompanied by significant deformation of the parts being joined. In some cases, when the parts being welded are of significant thickness and there is no gap between them, such deformations can even lead to the appearance of large cracks.

Low thermal conductivityThe thermal conductivity of stainless steel is 1.5–2 times lower than that of low-carbon alloys. This feature of the material leads to the fact that the parts being connected in the welding zone are melted even at lower (15–20%) current strengths than when welding products made of low-carbon steel.

Intergranular corrosionWith strong heating (more than 500 degrees Celsius), so-called intergranular corrosion occurs in stainless steels. This happens because layers consisting of chromium and iron carbide begin to form at the edges of the grains of the metal structure. This phenomenon can be avoided not only by careful selection of the welding mode, but also by forced cooling of the stainless steel parts being welded, for which you can use plain water. However, it should be borne in mind that only parts made of chromium-nickel steels that have an austenitic internal structure can be cooled with water.

Overheating of electrodes with chromium-nickel rodsDue to the low thermal conductivity of the materials being joined and their increased electrical resistance Welding stainless steel parts is accompanied by strong heating of the electrodes, the rods of which have a chromium-nickel composition. To avoid this undesirable phenomenon, use electrodes for welding stainless steel up to 35 cm long.

The most common methods of welding stainless steel

Welding of stainless steel products characterized by increased content chromium, can be performed using several technologies. This includes, in particular, the following types of welding:

- argon arc (using a tungsten electrode and AC/DC TIG modes);

- performed in MMA mode;

- semi-automatic in argon, carried out in MIG mode and using stainless steel wire;

- so-called cold welding for stainless steel, performed under high pressure (the name of this technology is due to the fact that it does not involve melting the metal during the process of joining it);

- seam technology and resistance spot welding.

The technology for welding stainless steel parts involves thoroughly degreasing their surfaces using acetone or aviation gasoline. This is done in order to reduce the porosity of the seam being performed, make the welding arc more stable, and thoroughly clean the edges of the parts being joined. Only after thorough cleaning can you begin to perform the operation using the chosen method. There are several basic methods for welding stainless steel parts, as well as technologies that are used quite rarely. In any case, the decision on how to weld stainless steel should be based on the specific conditions and requirements for the joint being formed.

Welding with coated electrodes (MMA)

Welding stainless steel parts using MMA technology, which involves the use of coated electrodes, is the most common technology. This method is quite simple, it can be used at home, but it does not allow you to obtain the highest quality seam.

Conveniently, this kind of stainless steel welding can be done even at home, but for this you will need a special welding machine called an inverter. In order for welding stainless steel with an inverter to produce a connection that is highly reliable, it is necessary to select the right electrode for a specific type. All electrodes used to weld stainless steel products are divided into two main types:

- with a rutile coating based on titanium dioxide (welding with such electrodes, which provide little metal spatter and a stable arc, is performed on DC and reverse polarity);

- with a coating based on magnesium and calcium carbonate (with such electrodes, stainless steel is welded using direct current of reverse polarity).

To understand which electrodes to use to cook stainless steel, just look at GOST 10052-75, which presents all types of such Supplies, and also stipulates which one should be used to work with the metal of a particular chemical composition. In order to choose ones that meet the requirements of this GOST, it is enough to know the grade of the metal from which the parts need to be connected.

All requirements for electrodes for welding stainless steel can be found by downloading GOST 10052-75 for free. pdf format follow the link below.

Manual and semi-automatic welding of stainless steel in argon (AC/DC TIG, MIG)

To perform manual welding of stainless steel in an argon environment, they are used. This technology, even at home, allows you to obtain high-quality and reliable connections for products that are not very thick. Welding with such electrodes on stainless steel is used mainly for installing communications from pipes through which gases or various liquids will be transported under pressure.

This technology has certain features.

- To ensure that tungsten, from which stainless steel electrodes are made, does not get into the molten metal in the welding zone, the arc is ignited in a non-contact manner. If it is not possible to do this directly on the part, then the arc is lit on a special coal plate and carefully moved to the workpieces to be joined.

- Welding stainless steel using this method can be performed with both direct and alternating current.

- Modes are selected depending on the thickness of the parts being connected. Such modes, in particular, include the parameters of the cross-section of the tungsten electrode, the diameter of the wire used as an additive, current parameters (strength and polarity), shielding gas consumption, and welding speed.

- It is very important that the alloy level of the filler wire is higher than that of the parts being joined.

- During the welding process, stainless steel electrodes should not make oscillatory movements. If this requirement is neglected, this may lead to disruption of the welding zone and oxidation of the metal in its area.

By using this technology, the consumption of tungsten electrode can be reduced. To do this, you need to keep the argon supply open for some time (10–15 seconds) after the welding process is completed. This procedure helps protect the hot tungsten electrode from active oxidation.

Semi-automatic, in fact, has few differences from conventional manual method. Its main difference is that the wire is fed into the welding zone using special equipment. Thanks to mechanization, the process proceeds much more accurately and at greater speed.

Thanks to the use of semi-automatic equipment, the following techniques for welding stainless steel parts can be implemented:

- jet transfer method, which allows you to effectively weld parts of large thickness;

- short arc welding - for connecting parts of small thickness;

- pulse welding – universal technology, which allows you to obtain high-quality and reliable connections and is the most profitable option financially.

More convenient and functional than a conventional oven. Water is useful for various purposes: soaking a broom, watering stones, rinsing after bath procedures and washing rooms.

The advantage of a water tank is that in this case the liquid is heated without additional waste of electricity or gas, which eliminates unnecessary expenses. In addition, the presence of a container eliminates the need to install a water heater, which also reduces the budget for the construction and use of a bathhouse.

Containers can be very different: they differ in shape, location and, of course, material. The most popular budget option are tanks for baths made of stainless steel, which have a number of undeniable advantages.

Stainless steel tank: features and advantages

In total, you can see three types of bath containers on the market: cast iron, stainless steel and enameled material. A stainless steel tank for a bath is considered the most acceptable solution, since it has an optimal price-quality ratio.

Stainless steel has high level thermal conductivity, due to which water is heated in a short time. Tanks made of this material do not require additional protection from high humidity and perfectly withstand the conditions typical for.

No less important is the fact that stainless steel tanks for baths withstand strong temperature changes. The material does not corrode, due to which it has long term services.

When compared with an enamel tank, the advantage of stainless steel is obvious: if a scratch or crack appears on the enamel, then the container needs to be changed, a steel tank is resistant to mechanical stress, it does not deform and retains its original shape.

Compared to cast iron containers, the tank also has its advantages: it has less weight, so it is suitable for different stoves, it is much cheaper, and it is easier to make it yourself. A stainless steel water tank is inferior only in that the water cools down faster in it than in a cast iron container, but it heats up quickly, so this drawback is considered insignificant.

How to make stainless steel tanks with your own hands?

If you do not want to purchase a ready-made oven with a container, then you can make one.

Step 1. Select the material for the stainless steel bath tank

The tank can serve you faithfully long years, but only if it is made correctly and from quality materials. The steel can be different; for the container used in the bath, you need to use stainless steel suitable for the production of cookware: 8-12X18H10 (304) and 08X17 (430). It must be resistant to extremely high temperatures, not deform in conditions of high humidity and be easy to maintain.

Most stainless steel tanks available in stores are made of 1 mm thick steel. In order to make a container with your own hands, it is better to choose thicker sheets - about 1.2-1.8 mm (depending on the volume of the container: the larger it is, the thicker the material is needed).

A cheap and simple option for making a tank is a piece of seamless stainless pipe. This option has several advantages:

- no need to cut sheets of metal and adjust them to size, which reduces the likelihood of errors and speeds up the process;

- minimal use of welding, which makes the manufacture of the tank simpler.

Step 2. Decide on the size and type of tank

Stainless steel water tanks come in several types, depending on their installation option: built-in, remote, mounted and on the chimney.

The built-in tank needs to be planned at the time you build the stove, because they are single design. The advantage of such a container is the rapid heating of water, but keep in mind that most of the heat will be spent on heating, so the heat output of the stove will decrease.

A remote stove tank is a practical and easy-to-use option. It can be done already for the finished oven.

It is also convenient that remote tank can be installed in a washing room and connected to the stove using pipes and a heat exchanger. In this case, you won’t have to run to the steam room for water to wash yourself after bathing procedures.

A tank on a stainless steel sauna pipe ensures fast heating of water, as well as maintaining it high temperature.

The hanging tank is mounted on one of the walls of the furnace. It heats up water and boils as quickly as possible. The disadvantage is that this makes the air in the steam room heavier.

Next you need to decide on the volume of the container. It is chosen based on how many people will be in the steam room at the same time. On average, it is recommended to have 20-25 liters of water per person. If you are planning to steam with a family of about 3 people, then stainless steel water tanks with a capacity of about 50-80 liters are suitable for you; for groups of more than 5 people you need to choose containers of more than 100 liters.

The next stage is preparing holes for water supply and drainage. You can prepare them using regular drill. The pipes to which the water pipes will be connected need to be welded to them.

Video - how to weld a stainless steel tank with your own hands:

Making water tanks for a stainless steel bathhouse with your own hands is quite possible. If you are an experienced welder, you can make a container from separate sheets of steel; if you still have little experience, then it is better to use a pipe. But if you are not confident in your abilities, we recommend buying stainless steel tank for water, because poorly made joining seams will cause the container to begin to leak quickly.

Do-it-yourself sauna stove: types and structural features

Do-it-yourself sauna stove: types and structural features

It's no secret that smoked meats are delicious. Just the aroma of smoked meat or sausages begins to awaken your appetite, but smoked meats are not always cheap. In addition, many have probably heard more than once programs about how some unscrupulous manufacturers “smoke” deli meats or fish with liquid smoke, choosing raw materials for their production, to put it mildly, of dubious quality.

stainless steel smokehouse

These are perhaps the main reasons that people, especially those living in private houses or having country cottage area, are increasingly thinking about purchasing home smokehouses. Only when preparing food yourself can you be sure of both the quality of the meat or fish that we put in the smokehouse, and that the delicacies will be prepared using high-quality, natural marinades and real, live smoke.

There are many options for smokers. At the same time, devices designed for hot smoking are more popular for the simple reason that the cooking method itself implies faster cooking of products than with the cold method. If a hot smoked smokehouse makes it possible to reduce the cooking process to several hours, with a cold method the products will be smoked not even for one day, but for several. However, there are combined modifications of smokehouses in which you can cook in “hot” or “cold” ways as desired.

Many craftsmen build excellent smoking units from bricks or wood. Metal barrels and buckets and even used refrigerators are used for smokehouses. But one of the most convenient and functional is considered to be a stainless steel smokehouse. Stainless steel smokehouses are most often used for hot smoking. Although the weight of such devices can be quite impressive, it is worth additionally noting that, due to their compactness, metal smoking devices are popular not only among owners of private households, but also simply among lovers of picnics and outdoor recreation. You can purchase such stainless steel smokehouses in special stores, and if you wish, you can build them yourself.

What can you build a smokehouse from?

Advantages of stainless steel smokehouses

a stainless steel smokehouse is a fairly good-quality and reliable unit that, with proper care, can serve its owners and be actively used for many years;

- the design and material from which they are made do not contribute to the formation of soot, so there is no need to worry about excessive soot formation;

- in such smokehouses you can smoke products both hot and cold;

- they are mobile and do not require special sites for installation;

- the design of such smokehouses is safe;

- the material is resistant to corrosion;

- they are easy to care for and use.

- This is far from full list advantages of such devices.

Advantages

Standard stainless steel smokehouse

Factory-made stainless steel smokehouses most often consist of a small box, inside of which grates for meat or fish preparations are installed on special hooks welded to the walls. Produced by industry various models smokehouses with two and even three tiers of grates for preparations. The top of such a metal box is closed with a lid, which has a special vent - a hole for removing smoke. In addition, such standard industrial smokehouses are provided with a tray for draining fat, a stand, as well as telescopic or simply removable legs on which it is convenient to install the smokehouse. Since the design of such smokehouses is collapsible, they can be used on almost any open fire and even on kitchen stove, if, of course, the size allows.

Standard smokehouse

Smokehouse with water seal

The design of smokehouses with a water seal deserves special attention, although it is almost no different from the standard ones. It is distinguished from conventional smokehouses by a U-shaped gutter, which encircles the entire container along the perimeter in its upper part. The lid is designed in such a way that its downward curved edge is located exactly in this groove, and if you pour a little water into it, then the air from outside will never get inside the smokehouse.

The lid with a water lock for jars, which are used in the production of homemade wines, is constructed on the same principle. In smokehouses, a water seal is designed for additional tightness. Thanks to it, the smoke from inside comes out exclusively through the hole in the lid, and Fresh air does not penetrate inside the device and does not cause sawdust to ignite. It is thanks to the water seal that the smoking process takes place in virtually airtight conditions. The stainless steel smokehouse with a water seal has whole line additional advantages over devices of standard design. Typically, such smokehouses are stronger, more durable and much less susceptible to deformation.

Smokehouse with water seal

Disadvantages of stainless steel smokehouses

The main disadvantages of stainless steel smokehouses are the same for devices of both designs. First of all, they are quite high cost and considerable weight. Stainless steel itself can no longer be called a cheap material, and products made from it even less so. The weight of the product depends on the size of the smokehouse and the thickness of its walls. For the manufacture of smokehouses, metal sheets with a thickness of at least 2 mm are used. And of course, the larger the smokehouse, the heavier it is, despite its portability.

DIY stainless steel smokehouse

Disadvantages of smokehouses

To make a metal smokehouse yourself, you will first need a stainless steel sheet 2 mm thick, as well as a piece of metal of a smaller thickness for the lid.

In addition, you will need the following tools:

- hacksaw for metal;

- jigsaw;

- Bulgarian;

- grinding wheel;

- metal tubes of round and rectangular section;

- metal scissors.

DIY stainless steel

If you want to somehow decorate your smokehouse, you will, among other things, need fire-resistant paint. Before you begin, you must carefully mark the stainless steel sheet strictly in accordance with the dimensions of all workpieces. Then all the parts are cut out with a jigsaw. In the front part of the main workpiece, a rectangular hole is cut out from below for a tray with wood chips.

All edges of the parts must be thoroughly sanded using a grinder grinder, cutting off and leveling all burrs and irregularities formed during the process of “cutting” the sheet. Otherwise, the edges of the parts will not fit tightly together and it will be difficult to achieve high-quality welding. The parts are then welded together, giving the workpiece the appearance of a box. It’s more convenient to weld to the back side first side panels, then weld the bottom of the future smokehouse to them.

Important! The stainless steel smokehouse can be any size. You just need to remember that the larger it is, the heavier it is. However, during production it is better to use ready-made, proven schemes, since the quality of smoking is influenced not only by the type of wood, the sawdust of which is used in the cooking process and the selected temperature, but also by the size of the smokehouse itself.

The World Wide Web is rich in offers ready-made schemes smokehouse, so anyone can easily find the device diagram they need, which will meet all their wishes and at the same time take into account all the features of smoking technology. To give the entire structure additional reliability from the inside, stiffening ribs are welded into it, which are conveniently made from rectangular pipes. It is better to place them in the upper part and in the middle of the workpiece. In addition, two more pipe fragments must be welded to the bottom of the workpiece, which will later play the role of guides when moving the box with sawdust. According to the size of the cut hole in the front part, a box for chips and sawdust is prepared. To improve the traction force in the smokehouse, several small holes need to be drilled in the bottom. To give stability to the entire structure, steel pipe legs are welded to the bottom. The most suitable height for such a device is 30 cm.

homemade smokehouse

If desired, you can make the legs removable, which will only add functionality to the device. By detaching the legs, the smokehouse can actually be placed even on a regular stove. The smokehouse lid can be made of a stainless steel sheet of less thickness than the walls and bottom. 1 mm is quite enough for her. Handles must be welded to the lid for ease of grip. You can simply drill a hole for smoke exhaust, but it is better to weld a small piece of metal pipe to it. Work on such a device for home smoking is completed by welding limiters and handles for carrying. An additional shelf can be attached to the legs of the smokehouse. The outside of the finished smokehouse can be painted with fire-resistant paint. Such rectangular portable smokehouses can quite efficiently replace large and bulky stationary smoking devices. With proper care they will last long enough long term, providing their owners with home-smoked fish and meat delicacies. A homemade stainless steel smoking device, of course, will cost the owners much less than buying a factory one. In addition, if you wish, you can build a stainless steel smokehouse with your own hands in just a few hours. Just keep in mind that this task can only be accomplished by truly experienced craftsmen, who also has experience in welding and working with an angle grinder.

Many people love smoked delicacies - they really have an unusual and pleasant taste. However, the cost of store-bought products is quite high, and they are not always safe, since their preparation uses a variety of additives and impurities that can be harmful to health.

If you love smoked meats, you have a summer cottage or you live in own home, we recommend making a device for smoking food yourself - this way you can prepare delicious and pleasant delicacies, always fresh and absolutely safe for you and your household.

Today we will talk about how to make a stainless steel smokehouse with your own hands, and the drawings will help you better understand our tips and recommendations. We will also talk about many other interesting and useful things related to this topic.

Why is it better to smoke yourself?

Smoked products offered to customers in stores today are produced using special technologies that involve the use of liquid smoke. This is due to the fact that in factories and food processing plants they try to prepare as much as possible more meat and fish to meet the needs of everyone. However, such smoke contains various negative additives. In particular, we are talking about phenols and benzopyrenes.

Benzopyrene is especially dangerous - Chemical substance I hazard class. The danger lies in the effect on the human body and environment, while the changes caused by it are irreversible and cannot be restored. It is one of the most common carcinogens, resistant to extremely low and high temperatures and capable of bioaccumulation. When ingested, it has a mutagenic, hematotoxic and embryotoxic effect.

The independent process of preparing smoked meats has a number of undeniable advantages, including:

- cooking is carried out according to the recipe you choose;

- you can prepare many products at one time, providing yourself with delicacies for a long time - after all, they are stored well;

- the degree of smokedness of the products is determined independently;

- the choice of firewood and wood chips is also carried out independently, which determines the taste characteristics of meat or fish;

- these are always fresh products, because it is not known how long the food offered in stores was stored in warehouses;

- regular, “natural” smoke is used, without any additives or additives.

Why stainless steel?

Smokehouses made of stainless steel are considered ideal, since it is safe and also durable, that is, it will serve you for a long time even if it is used regularly.

Choose the shape and size of the unit depending on how often you plan to use it and how much product you want to get at a time. Yes, small rectangular devices recommended for small families. But large, round, barrel-shaped ones are suitable for those who want to receive a lot of food at one time - for example, those who have a large family. Or entrepreneurs selling smoked meats.

Consider also the fact that there are special types of stainless steel. For example, AISI 304 deserves mention - it is a food grade metal that has the following characteristics:

- perfectly withstands temperature changes, that is, the device can be used even in winter, in frosty conditions;

- Designed for contact with salts and various aggressive environments.

There are two types of smoking - cold and hot. The first is a longer process that allows you to obtain products intended for long-term storage, but they are a little harsh, although they have excellent taste. The second is a faster process, which will only take a couple of hours. Such products are juicy and attractive in appearance.

We create a smokehouse ourselves

Now that you know all the advantages of making your own, as well as the positive characteristics of stainless steel, let’s talk about how to make your own unit for creating goodies.

When arranging such a device, it is important to take into account the main rule - oxygen should not penetrate inside, otherwise in this case the sawdust will not smolder, but burn fully, which will negatively affect the entire technology for preparing fish or meat.

How to make a stainless steel smokehouse with your own hands - video instructions

In order to prevent the penetration of air, it is necessary to create a water seal - the presence of water will prevent the entry of oxygen and allow the wood chips to simply smolder, emitting smoke.

.jpg)

Process diagram

The cooking process is carried out according to the following scheme:

- the unit has two tanks - one for firewood, the second for food;

- an option is also possible with one tank - only for food: in this case it is installed on a stove or fire;

- heat comes from burning wood, heats a baking sheet with sawdust and it emits smoke;

- As a result, smoking occurs.

As you can see, the scheme is simple and clear. There is nothing complicated about it, and therefore now the only thing left to do is to make a cooking device.

Stainless steel - perfect material, since it is safe and durable, does not emit harmful fumes, ensures uniform heat distribution, creating an optimal microclimate inside the tank.

Some who want to prepare delicacies themselves come up with different kinds similar devices. For example, using this:

- bucket;

- refrigerator case, etc.

In addition to the chamber for firewood, there are shelves or hooks for food:

- meat;

- lard;

- fish;

- cheese, etc.

How it's done

The manufacturing process involves the following steps:

- purchase stainless steel sheets;

- cut it according to the size of your future smokehouse;

- for medium devices, where two poultry carcasses will fit or there will be two levels for small pieces of meat, the dimensions are as follows: length - 70 centimeters, height - 40 centimeters, and width - 40 centimeters;

- the prepared sheets are joined - argon welding is used for this, but another one is also suitable;

- for gratings, use stainless steel wire;

- make a hole in the top cover to allow smoke to escape;

- Place a tray under the food racks to catch grease.

.jpg)

To ensure that, under the influence of high temperatures over time, the structure does not change its shape or begin to tilt, choose only high-quality metal. The thickness of the steel must be at least three millimeters.

.jpg)

In the upper part where the lid is installed, you need to make small grooves around the perimeter. Water will be poured into them, which will provide a kind of hydrobarrier, guaranteeing protection against air penetration.

Smoking rules

To prepare delicious delicacy, it is important to choose the right firewood and sawdust. It is best to use wood chips:

- apple - they create excellent smoke, but they have almost no aroma;

- plum - have a more pronounced aroma than apple;

- cherry - have the best aroma, giving the products a unique taste;

- apricot - give a slight sweetish taste.

Naturally, you can safely combine different tree species. And if you want to get a natural, natural aroma without any sweetish aftertaste, then it is best to use wood chips obtained from:

- oak;

- aspen;

- alder branches.

A little juniper will also help create incredible flavor.

.jpg)

When the meat is prepared and the wood chips are selected, you can begin the process:

- sawdust is placed at the bottom;

- next - install a baking tray for receiving fat;

- food is placed on the grates;

- The chamber is closed with a lid and water is poured into the grooves.

The smokehouse is placed on the fire or stove and cooking begins. Under the influence of high temperature and due to the lack of oxygen, the wood chips begin to smolder and emit smoke.

.jpg)

The cooking speed depends on what products you use:

- meat - up to two hours;

- fish - about half an hour;

- cheese - up to forty minutes.

The whole procedure will not require much wood chips and sawdust. They should cover the roasting pan in an even layer.

Features of smokehouse care

In order for your smokehouse to work as long as possible, provide it with high-quality care - regularly clean it from grease and carbon deposits.

Also clean other surfaces from any types of contaminants.

For cleansing you can use regular detergent, soda or citric acid. It is advisable to clean and ventilate every time after cooking, otherwise over time this coating will simply be irremovable.

Making a smokehouse from ordinary stainless steel is not so difficult. Use quality material and follow our advice. So are you with minimal costs, including temporary ones, you will make the ideal device for preparing unusually tasty delicacies!

How to properly smoke food in a smokehouse with a water seal