Insulating the roof of a wooden house: how to insulate the rafter system, partitions. Insulating the roof from the inside with your own hands Insulating the roof along the rafters from the inside

Properly organized insulation in the house is the key to comfortable living conditions. If the main floors and wall structures do not have high heat-saving properties, then the functions of ensuring a favorable microclimate are transferred to insulating materials. The most effective solution to this problem is to insulate the roof along the rafters; photos of how this process occurs are presented in the article.

Nuances of choosing material for insulation

The material for insulation in the rafter area is usually selected taking into account the thermal insulation potential of the structure, but this is far from the only selection criterion. The supporting structure for slopes has fundamentally important limitations in terms of additional equipment. The main one is the weight load, so the material must be light and small-sized, since the fixing devices in the case of using large-format panels will also provide additional weight.

As for the form factor, subject to structural compatibility, experts recommend using tiled and rolled products. The only exception applies to backfill materials that are appropriate to use on the ceiling of an attic or attic. It is advisable to carry out insulation of the roof along the rafters from the inside in thin layers, taking into account the possibility of installing a protective coating. In this case, it will be better to use products with external metallized layers that provide a barrier against mechanical stress.

In addition, you should adhere to the general rules for choosing materials for arranging the roof and roofing system. It is important that the insulator is non-flammable and biologically resistant. formed by lumber, in itself, without protective impregnations, is vulnerable to the development of fungus and mold, not to mention the support of a flame. In this sense, the internal insulating coating should become a barrier against the negative factors of possible destruction of beams and support posts.

Don't forget about waterproofing

As experts note, moistening the insulating material by just 1% can reduce its thermal conductivity by up to 30%. IN winter time year, this percentage increases and can cause destruction of the insulator structure. Therefore, roof insulation technologies along the rafters necessarily include the inclusion of a hydraulic barrier in the insulating structure. It is desirable that the moisture-resistant shell also combines the qualities of a vapor barrier.

Hydrological insulation materials are primarily rated based on strength, abrasion resistance and fire resistance. These are mainly artificial products, so biological threats are excluded. The optimal solution can be a roofing membrane based on polypropylene or polyethylene. If you apply a modification of the film with reinforcing fabric or mesh, then insulation of the roof along the rafters can be done without a special counter-lattice on the outside. It is recommended to lay directly on a layer of thermal insulation, which will reduce the amount of work and costs. This waterproofing agent directs moisture in one direction - away from the surface of the insulation. Condensation also collects on the reverse side, after which it drains or evaporates. An important nuance when arranging layers of waterproofing is to lay them with the correct side to the insulation. Usually the same membranes are marked with special inscriptions indicating the front or back side.

What should be the structure of the insulating “pie”?

Configurations for placing thermal insulation in can vary depending on the characteristics of the roof, insulation requirements and rafter layout. In any case, the outer layer will be represented by the roofing material - it can be a metal sheet, bitumen shingles or slate based on asbestos concrete. This covering can also be fixed to rafter beams, but most often intermediate slats are used to make the joint secure. A kind of lathing is formed, with a heat insulator mating to it on the inside. But before that comes external isolation. Among the subtleties of roof insulation along the rafters, the importance of maintaining ventilated gaps should be noted. That is, there should be 2-3 cm between the conventional mineral wool slabs and the roofing for air circulation. It is this indentation that will be provided by the sheathing slats.

Additionally, thermal insulation on the outside can be preceded by vapor barrier and wind protection. The presence of the last layer depends on the type of roof. For example, modern models bitumen shingles and ondulin take on part of the insulating functions, eliminating the need to lay additional technical layers. On the attic side, the technology for insulating the roof along the rafters also involves the inclusion of hydro- and vapor barrier films, which, depending on their own structure, can be covered with sheathing and subsequent cladding or remain open. Despite its impracticality, the second option can be justified by the fact that the owner can always assess the condition of the insulation during an external inspection. And, on the contrary, under the layer of lining the defects that have formed will be hidden, due to which dampness may appear.

How to properly insulate between rafters?

The most common insulation scheme is one in which thick slabs can be used. Moreover, the size of the segments is selected so that the width is 10-15 cm larger than the gaps between the rafter beams. This distance will be used as sheathing cells, into which the heat insulator is laid according to the classical system. Width tolerance is necessary for tight integration of insulation into free niches without gaps. As for the thickness, it is selected lower relative to the protrusion of the rafter legs. This condition is necessary to save space for the same waterproofing or other technological and protective coatings. Proper insulation roofing along the rafters is carried out so that a dense and level base made of insulating material in the structure of load-bearing beams. To do this, it is necessary that the laying surface also has the correct geometry, and this will again depend on the characteristics of the roof.

The subtleties of thermal insulation under the rafters

Filling the free space between the rafter legs is simple and practical option insulation. Thus, the supporting structure is given additional rigidity, the structure for placing the insulating material receives the necessary retaining elements, and the niches in which cold air can “walk” are also filled. However, this option is not always possible due to the following reasons:

- in the space between the rafters.

- Insufficient structural rigidity for placement additional materials.

- The use of an insulator, which in principle cannot be placed in the grooves.

In such situations, you can use an alternative arrangement of the heat insulator on the rear side. But even in this case, there are structural nuances of roof insulation along the rafters, which consist in the problems of moving the insulating layer beyond the level of the supporting structure. In this case, the niches between are covered with solid material (plywood, chipboard, etc.), and insulation is laid on it. It is not practical to use thick slabs in this configuration as it would require an additional structure, which would significantly increase the load and reduce the available space in the attic. But it is allowed to use thin rolled material, for fastening of which, together with waterproofing, slats and a protective reinforced film will be sufficient.

Insulation technology over rafters

The reverse of the previous technique for laying the heat insulator is one in which the material is located not on the back side, but on the outside - between the roofing covering and its supporting structure. But this method also requires compliance with certain structural conditions, the main one of which is the design preservation of space for organizing roof insulation along the rafters. Laying in in this case carried out from above truss structure with a superstructure in the form of a sheathing. When preparing for installation, it is necessary to close load-bearing beams sheet wood-chip panels. The sheathing ribs are mounted on a flat surface, between which (a distance of about 50-60 cm) the insulator will be laid.

The upper part of the material is also covered with waterproofing and other technological coatings depending on the specific requirements. There can be two options for external closing coating. In the first case, the roof insulation over the rafters is left unfinished. That is, in relation to the back side of the roof, the same waterproofing remains open. This option is good because it leaves a free area for air ventilation - in the place of interaction of insulators and roofing material there are surfaces that are resistant to negative humidity and biological factors. The second option involves the installation of small-format sheathing with intermediate power battens along which the roof will be laid. This scheme is good because of the additional mechanical and wind protection of the insulators, but in this case the ventilation effect of the under-roof space is reduced and the wood finish of the insulation remains less protected from contact with moisture.

Combined insulation scheme as the best option

In this case, comprehensive thermal insulation of the roof structure is implemented in three directions. That is, the roof will be insulated over the rafters, between the beams and above them. It is immediately worth noting several nuances of using this configuration, since it has many features:

This scheme is not suitable for use in small houses. Moreover, it is usually used in full-fledged attic rooms, where, in principle, a more solid roof structure is provided and there is enough space for the installation of complex technological elements. On the other hand, it is the combined technology of laying roof insulation along the rafters that makes it possible to turn an attic into a living space for the winter. Even at the roof design stage, it is necessary to provide for the possibility of installing three levels of insulation. Technically, installation of this structure is carried out if the following conditions are met:

- Two battens are organized inside and outside in relation to the rafter structure. That is, beams for rafter legs are initially selected with large dimensions, preferably with metal reinforcing plates.

- It is planned to include supporting vertical posts to hold not only the truss structure, but also the insulation. To evenly distribute the load of the supporting area at the level of roof insulation, metal sheets or chipboard panels with grooves for fixing the racks are mounted on the inside of the rafters.

- As each new layer of insulation is laid with panels closing the next sheathing, it is necessary to make technological holes for the future passage of ventilation and chimney pipes. In a completely closed, formed insulation structure, this operation at all levels will be difficult to perform.

Methods of fastening and arrangement of insulators - what to consider?

Basically, two methods of installing thermal insulation materials are used: adhesive and mechanical (using hardware). Each of them has its own nuances of application, so they are worth considering in more detail:

- Adhesive fastening method. If you plan to insulate the roof along the rafters with your own hands, this method will be preferable. To implement it, it is enough to clean the laying surface in the form of the same plywood sheet or the back side of the roof, apply the adhesive mixture and fix the insulator. This technique is used for both roll and tile insulation, but in both cases it is necessary to choose the right composition. When installing it yourself, beginners are recommended to use ready-made dry mixtures. More experienced roofers use two-component products, which can be further modified to improve certain performance qualities. For both cases, it is recommended to use products from Ceresit, Soudabond and Insta.

- Installation using mechanical fasteners. The complexity of this method lies in the fact that the rafter system is not the most successful base for installing hardware. By the way, unsuccessful implementation of a large-format dowel into a weak beam can cause future rotting of its structure or the spread of cracks. How to properly insulate the roof along the rafters to avoid such phenomena? Firstly, you should, in principle, abandon large-sized nails, anchors and dowels. The emphasis is not on forceful grip (as a rule, insulation materials are light in weight and do not require rigid fixation), but on holding them in the desired position. To do this, it is enough to use umbrella thin dowels. In the case of rolled materials, you can completely limit yourself to mounting brackets, installing them with a construction stapler. Secondly, the installation points, together with the fasteners, are pre-treated with antiseptic and other bioprotective solutions for wood, which will prevent the processes of rotting, the development of mold and mildew inside the structure.

Features of roof insulation along rafters with mineral wool

This is the most famous material for thermal insulation. Despite certain disadvantages, such as extremely low protection from moisture, mineral wool is readily used in roofing. This material can be used to perform both partial and complete insulation of the roof structure. It is advisable to use slabs with a thickness of 20 cm (minimum) if we are talking about a region with cold winters. If there are structural restrictions on thickness, then the thickness is reduced to 10-15 cm. By the way, the same rules apply when insulating the roof along the rafters with foam plastic, but with one fundamental difference. Foam plastic, for all its advantages as a heat insulator, has a drawback associated with unsatisfactory sound insulation qualities. Therefore, in addition to auxiliary technical layers of insulation, it may additionally be necessary to lay noise-reducing material.

As for installation, it is necessary to note the nuances of observing safety precautions when insulating the roof along the rafters in this way. How to properly lay mineral wool? Only wear sealed gloves, a respirator and construction glasses, as this material emits toxic substances. Technically, installation is carried out according to the general scheme on the sheathing with the obligatory coating with a waterproofing agent, but it is also additionally recommended to apply thin retaining slats in the central parts of the slab placement.

Features of using foam insulation

This is a rather specific material from the point of view of roof thermal insulation; it is rarely used in this capacity, but with proper installation, such a move is possible. Foam insulation usually means polyurethane foam, the qualities of which determine the non-standard nature of this type of insulation. To begin with, it’s worth considering what are the benefits of roof insulation along the rafters based on a foam composition? This is the best option in terms of design. Spraying polyurethane foam allows you to lay the material in different configurations, regardless of the complexity of the area; the foam will take any shape. In addition, this is the lightest heat insulator, so you don’t have to worry about the rafter system becoming too heavy.

However, there are also strict restrictions on the use of polyurethane foam on the roof. This material supports combustion (at least it smolders slowly, also releasing toxic substances), and is not compatible with metal sheet roofing(excessive release of condensate and minimization of the ventilation gap) and cannot be used in places where exposure to high temperatures is expected (if the roof is very hot from the sun, destruction of the material will occur). But does this mean that insulating the roof along the rafters with polyurethane foam should be abandoned? Not at all, since its negative properties are not of particular importance when spot sealing the so-called cold bridges. That is, foam insulation can be used zonally as a supplement to the main insulation.

Conclusion

When deciding on the choice of roof insulation technology, it would be a good idea to turn to special offers from thermal insulation manufacturers. Large companies are meeting the consumer halfway, trying to simplify installation tasks when using their products. For example, roof insulation along the rafters with Penoplex is distinguished by the use of a tongue-and-groove locking edge, which completely eliminates the question of choosing a fastening technique and minimizes gaps at the joints. In turn, the Knauf company offers special solutions for pitched roofs. This roll material, which is easy to cut, takes the desired shape of installation and does not require further protection with a waterproofing agent, since its structure contains proprietary water-repellent impregnation Aqua Statik. No less interesting insulation options for the most different conditions operation is also offered by manufacturers Izover, Technonikol, Ursa, etc.

In houses where there are attic roofs, the roof serves as reliable protection for the entire building from the effects of precipitation.

And sometimes attic spaces are also used as living quarters, namely on mansard-type roofs.

note

If the attic or attic is used as living quarters, then along the slopes mansard roof it is necessary to lay a thermal insulation layer.Thermal insulation provides:

- corrosion resistance;

- sanitary and environmental safety;

- long-term preservation of heat in the room;

- protection against condensation;

- noise protection;

- frost protection;

- protection from heating.

Materials for roof insulation

In general, all thermal insulation materials can be divided into:

- porous (or porous-fibrous), which contain interconnecting gas cavities.

- cellular, which contain isolated gas cavities: polyurethane foam; expanded polystyrene; polyethylene foam; foam rubber.

It is customary to use the following types of insulation:

- Polystyrene foam (expanded polystyrene), which at a stretch can be called thermal insulation material due to the complexity of high-quality insulation.

- Minvatu. Mineral wool insulation may contain staple fiberglass or stone. From experience, I can say that the highest quality thermal insulation properties are found in materials with stone inclusions, namely basalt insulation.

note

In my work, I never use and do not recommend using foam or fiberglass-based mineral wool. We insulate only with basalt stone insulation, because we bear responsibility for the work performed and guarantee its maximum quality.Features of basalt insulation

Basalt insulation - belongs to the group mineral wool insulation and are made from various rocks.

Stone wool consists of the finest fibers, chaotically connected to each other and forming cells filled with air, so the material is characterized by low density and a high content of air inside.

Advantages of basalt insulation

- High thermal insulation qualities. The heat exchange between the cold and warm sides of the structure is noticeably reduced.

- Good soundproofing of the premises.

- Durable and easy to install. Basalt insulation is not afraid of temperature influences and does not shrink.

- Basalts have a non-combustibility class of NG (fireproof frame). This means that by saving 15-30 minutes from the fire, many lives can be saved.

- This is the most common thermal insulation in Russia. Factories producing basalt insulation materials are scattered throughout the country in great numbers.

- Basalt thermal insulation is the most environmentally friendly compared to other insulation materials.

- Hydrophobic qualities. Stone wool fibers are naturally water-repellent, and special additives are used in production that can enhance their water-repellent properties.

note

And yet, you must understand that at any stage of construction, if water has access to the mineral wool thermal insulation, the mineral wool will soon stop working, since under the influence of water the basalt will crumple and lose its thermal insulation properties.For this purpose, vapor and waterproofing are used.

Subtleties of the thermal insulation process

In the process of thermal insulation of a roof, several fundamental insulation structures can be distinguished:

- between the rafters,

- under the rafters,

- on top of the rafter structure,

- in a combined way.

Insulation between rafters

This method is the most widely used.

Need to remember:

1. When installing a roof with single-layer ventilation and laying a diffusion film, the insulation layer is installed to the entire height of the rafters. If anti-condensation (micro-perforated) roofing films are used for insulation, then the thickness of the insulation will be 5-10 cm less than the height of the rafters.

2. To avoid the formation of cold bridges, insulation layers must be laid with the slab joints shifted by at least half their length.

3. It is necessary to seal insulating materials at their joints, avoiding any gaps;

4. For ease of installation and quality control of insulation, with an insulation thickness of 200 mm, it is better to use 2 100 mm slabs than 4 50 mm slabs;

Attention

Use maximum thickness insulation!

Possible insulation defects:

- loose connection of thermal insulation to the side surfaces of the rafter legs

As a precaution, it is worth laying insulation with a width of 10 - 15 mm greater than the free distance between the rafter legs or, if the rafters are not parallel, cut trapezoidally.

- insufficient ventilation of thermal insulation

To avoid this, sufficient and constant clearance is necessary.

Insulation under the rafters

This method of insulating residential roofs is rarely used.

Advantages

- fairly high reliability

Flaws

- the internal area of the room is reduced

Insulation over the rafter structure

This type of insulation is used mainly for insulating metal structures where metal rafters are present.

Advantages

- there are no breaks or cracks in the thermal circuit;

- roof supporting elements arrive in constant temperature and humidity, metal rafters are not subject to temperature fluctuations and are not deformed

- internal space is not reduced

Flaws:

- complexity installation work on roofs of complex shapes

- the need to use protective coatings for metal structures and wood.

Roof insulation using a combined method

Attention

This is the most efficient look insulationThe combined method includes insulation according to the scheme between the rafters and on top of the rafters. In this case, the so-called “cold bridges” - unaccounted cold flows - are completely excluded.

The problem of high heat loss, and as a consequence, financial costs, will be solved by laying insulation between the rafters.

As you know, warm air is much lighter and rises, so economical and thrifty homeowners are concerned about insulating the roof of their home.

Materials used for roof insulation

Modern market building materials offers a lot of base options for creating decent roof insulation. The most common are considered to be glass wool and mineral (basalt) wool.

Glass wool is represented by the thinnest glass threads, and therefore requires care when working to avoid small particles getting on the skin, eyes and respiratory system.

Glass wool is quite elastic, durable, and fire resistant. The material is publicly available and has a low cost, which makes its use very practical and popular.

Mineral wool occupies a leading position among other materials. It is presented in the form of gabbro-basalt fibers, bonded with various combined substances.

Minvata is good insulation between the rafters. It is more elastic than glass wool and safer, but despite this, it requires necessary measures precautions.

Mineral wool has the following characteristics:

- fire resistant and not subject to combustion;

- the elasticity of mineral wool allows you to easily place the slabs in the required space;

- the constant shape of the slabs makes it possible to avoid gaps between the insulation and the rafters;

- retains heat well and has high thermal insulation properties;

- ease of installation.

An important difference between the presented material is its affordable price.

Despite many positive characteristics, basalt wool has a high hygroscopicity rate.

Over time, the material absorbs a large number of moisture and gets wet, losing its thermal insulation properties.

Preparing the roof for laying insulation

If you follow the technology, then the insulated roof consists of several layers, replacing each other.

When insulating the roof, it is necessary to observe consistency, because each component element performs its assigned function and must be located in a designated place.

In addition, during the process of roof insulation, it is important to ensure proper ventilation, vapor barrier and waterproofing.

Roof insulation by laying material between the rafters is the most popular, despite the difficulties in installing the heat-insulating layer.

In this case, a layer of insulation is laid along the height of the rafters and fastened between them.

In this regard, it is better if the size of the prepared insulation sheets is 20 - 30 mm larger than the distance between the rafters.

If this is not possible, then there will be a need to create additional fastenings that will keep the insulation from falling and sagging.

This can be a fishing line, stretched and fixed with nails driven into the lower edge of the rafter legs.

You should think about the waterproofing layer in advance. If the roofing material has not yet been laid, then a waterproofing superdiffuse film is spread on the rafters, designed in such a way that it does not allow moisture to pass through from the outside, but the opposite side– couples.

They begin to attach the film from the eaves overhang, moving upward. The canvases are laid with an overlap of 10 - 15 centimeters, while securing the joints with adhesive tape.

The membrane is attached to the surface of the rafters using construction staples or nails with a wide head to avoid damage.

It is very important not to stretch the waterproofing membrane: when the temperature drops, the material contracts, which can lead to its damage, and consequently to damage to the entire structure. The membrane should be laid with a slack.

As a rule, roof insulation is carried out before installing the roofing material.

However, there are situations when it becomes necessary to insulate the roof from the inside: lack of thermal insulation, insufficient amount of insulation installed previously, or when insulating an old house.

In this case, laying insulation is possible, but it will not be as reliable and durable.

The waterproofing film is laid indoors without dismantling the roofing material.

For this purpose, it is necessary to wrap the rafters with film and lay it in the space between them, and then follow the standard pattern.

However, this design does not protect the rafters from the elements, which can lead to premature wear.

To do this, it is stuffed on top of the waterproofing layer. wooden sheathing from slats secured with self-tapping screws.

It is good if holes for fastening are prepared in the slats in advance, which will avoid damage to the waterproofing film.

Technology for laying insulation between rafters

The next step is the actual installation of the insulation. Accordingly, the work is carried out indoors. The mineral wool must be released from its packaging in advance so that the slabs take their shape.

After this, the material is cut into the required sizes, adding 2-3 cm for laying the material “by surprise”.

You can cut the insulation with a construction knife, without forgetting about safety measures.

When working, you should use a respirator, goggles, gloves, thick clothing to avoid small particles getting into your eyes, Airways or on the skin.

When the insulation is prepared, begin its installation. The cut slabs are placed in the spaces between the rafters, and the edges of the cut slabs are slightly bent.

You should press on the central part of the sheet being laid, due to which it will “spring” - this will lead to straightening of the edges.

A vapor barrier film is attached over the fixed mineral wool elements, protecting the heat insulator from vapors coming from the living space.

The membrane is laid perpendicular to the rafters, with an overlap of 10–15 cm, taped with adhesive tape and secured with construction staples to the rafters.

To create the necessary layer for ventilation, which promotes the evaporation of moisture, a wooden grid is placed on top of the vapor barrier layer. The most commonly used slats are 2.5 cm thick.

The final stage of insulation is the installation of finishing material. It can be attached directly to the surface of the rafters using special screws or to a sheathing of wooden slats.

Thus, the insulation of the roof is completed: the materials are located in designated areas and perform their assigned function.

It is important to comply the necessary conditions, procedure and technology for using materials, then insulating the roof will not cause you much trouble.

In addition, the structure is subject to repair. If necessary, you can dismantle the finishing material, sheathing and vapor barrier layer, make repairs, and then install everything back.

When building a private house, you should pay attention not only to the thermal protection of walls and floors, but also to the insulation of roof structures. The temperature and humidity conditions of the room, and even the service life of the structures, depend on the correctness of roof insulation measures. You can do the installation of thermal insulation material yourself.

The need for insulation

Everyone knows from school physics that heated air rises. If there is no thermal insulation, nothing prevents him from leaving the building. Because of this phenomenon, a large amount of heat loss occurs through the roof or attic floors. Absence necessary protection from cold and loss warm air may lead to the following problems:

- lowering the room temperature;

- increased heating costs in winter;

- condensation on the inner surface of the roof;

- the appearance of mold or mildew on roof elements;

- destruction or damage to load-bearing structures, and bringing the house into disrepair.

The insulation of roof structures, as well as the insulation of walls and ceilings during the construction of multi-apartment residential buildings, is necessarily checked by state or private expertise at the design stage. Thermal insulation of a private cottage depends entirely on the future owner; no one checks its availability and wise choice, but this does not make it lose its importance.

Insulation methods

Do-it-yourself roof insulation largely depends on the roof structure. There are two types of roofs: flat and pitched. Most often, flat roofs are used for the construction multi-storey buildings, but it can be used in the construction of a private cottage. Flat roofs can be constructed in two ways:

In inversion, the order of layers has been changed. This technology is used when arranging a serviceable roof. The following can be used as insulation material in both cases:

- Styrofoam;

- extruded polystyrene foam;

- mineral wool (in slabs);

- expanded clay

The latter is quite cheap, but has lower thermal protection characteristics. In most cases, roof insulation is applied from the outside. This allows you to simplify the installation process and make protection from the cold that is competent from a thermal engineering point of view.

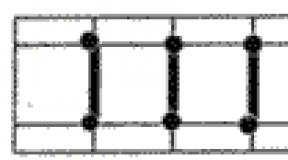

Layout of insulation between rafters

Layout of insulation between rafters

It is necessary to remember the strength of the material; additional measures will also be required to protect the insulation from mechanical damage.

When building a private house, the option with a pitched roof is most often used. It allows you to equip an attic or attic and has a more attractive appearance. Roof insulation wooden house or any other can be done in several ways:

- laying material between the rafters (the most common);

- laying insulation on top of the rafters;

- fastening from the bottom of the rafters.

Material selection

Insulation of the roof of a wooden house or building made of other materials is carried out using the following materials:

Rarely used materials include:

- expanded clay;

- sawdust.

Scheme of roof insulation with mineral wool

Scheme of roof insulation with mineral wool

Bulk materials are used to protect against the cold outside. They have an attractive price, but are quite difficult to install, so they are not widely used. It is better to use more modern technologies.

In general, materials for thermal protection measures must meet the requirements:

- safety, absence of harmful effects on humans;

- environmental friendliness;

- light weight to prevent excessive stress on rafter system;

- resistance to creasing and sagging, sufficient strength and rigidity;

- sound insulation characteristics (especially important when using metal roofing);

- fire resistance (especially important for wooden construction);

- if possible, good vapor permeability, which will provide additional ventilation of the room;

- good thermal protection characteristics.

One of the most important characteristics of a material is its thermal conductivity. This value must be indicated by the manufacturer. The lower the value, the smaller the thickness of the insulation will be needed. If you are not short on money, it is better to choose materials such as mineral wool or expanded polystyrene. The values of their thermal conductivity depend on the manufacturer and are in the range of 0.03-0.04 W/(m2*ᵒC).

Thickness calculation

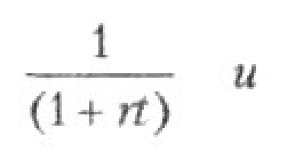

It is important not only to choose the right material for insulation, but also to correctly calculate its thickness. Insufficient will lead to condensation, and excessive indicates waste of money. You can select the value “by eye” based on general recommendations, for example, regardless of the type of roof (pitched or flat), for insulation with mineral wool or expanded polystyrene, a layer thickness of 150-200 mm will be required.

It is best to perform a full thermal calculation that takes into account modern comfort requirements and allows you to find the ideal balance of cost and quality. For a specialist, performing such a calculation will not be difficult. A person who is far from construction can use examples of calculations or the Teremok program, which is freely available and quite simple and understandable.

Competent calculations at the design stage are aimed at saving the budget and ensuring the reliability of thermal protection.

Their implementation will not take much time, but will allow you to avoid cost overruns during construction and additional costs for repairs during operation.

The process of insulating a flat roof

Depending on the type of roof, the insulation technology will be different. For flat roofs Usually the following layer order is observed:

- load-bearing structure (most often reinforced concrete covering);

- vapor barrier layer;

- thermal insulation material;

- cement-sand screed (reinforced for weak materials);

- waterproofing carpet, which serves as a finishing coating.

If absolutely necessary, you can carry out work from inside the room, but this method has several disadvantages:

- reducing the height of the room;

- transfer of dew point inside the structure;

- inconvenience of work.

Thermal protection of pitched roofs

Before properly insulating the roof of a house, you need to understand the procedure for carrying out the work. pitched roof in the vast majority of cases, insulation is between the rafters. Insulating a roof from the inside with your own hands is a completely feasible task. It is important to follow the correct order of laying materials from bottom to top:

- interior decoration;

- bottom sheathing;

- vapor barrier;

- rafters with insulation between them;

- waterproofing;

- wind protection;

- sheathing;

- roofing material.

When the thickness of the insulation is greater than the height of the rafters, counter-battens are installed. It is better to use modern diffusion membranes as wind protection and waterproofing.

Proper insulation, regardless of the type of roof, requires a careful approach. To avoid problems during operation, it is necessary to select the correct insulation thickness, choose a reliable manufacturer and follow the installation technology. Fulfillment of these conditions will allow the roof to last a long time and help maintain normal temperature and humidity conditions in the building.

We insulate the roof correctly: how to avoid mistakes

Insulating the roof will create warmth in the house. We will describe in detail how and what is the best way to insulate the roof of a private house in this article.

Proper insulation of the roof of a house: technology and video

Insulating the roof of a house - important stage construction or overhaul roofs. The choice of technology for installing a heat-insulating layer depends on the configuration of the roof, the type of insulation and the requirements for the room located directly under the roof.

How to insulate a roof to significantly reduce heat loss at home? First of all, you need to choose the right materials for insulation and strictly adhere to the installation technology. A high-quality insulated roof increases the thermal efficiency of the house by 15%, allowing you to turn the attic into a room suitable for year-round use.

How to insulate a roof to significantly reduce heat loss at home? First of all, you need to choose the right materials for insulation and strictly adhere to the installation technology. A high-quality insulated roof increases the thermal efficiency of the house by 15%, allowing you to turn the attic into a room suitable for year-round use.

The highest demands are placed on insulating the roof of a residential attic of houses located in areas with cold winters. The roofing pie of summer attics or exploited attics may include more thin layer thermal insulation. The roof, under which an unused attic is located, is usually not insulated - thermal insulation is mounted on the attic floor or the ceiling of the living premises. An uninsulated non-residential attic is well ventilated, which prevents rotting of the wooden elements of the roof frame.

When installing pitched and flat roofs, we use different ways roof insulation.

Thermal insulation of flat roofs

How to make an insulated roof when installing a flat roof? It should be noted that a flat roof can be insulated both from the outside and from the inside.

The composition of the flat roof pie includes:

- vapor barrier;

- heat insulator;

- waterproofing layer made of rolled material;

- bulk layer (drainage + cement-sand mixture).

External insulation is most conveniently performed using mineral basalt wool. You can also use polystyrene foam and other rigid insulation materials. It should be taken into account that polymer insulation cannot be used when installing roofing coverings with high fire safety requirements.

Insulation of a pitched roof

The roofing pie of a pitched roof is made with insulation along the rafters. It is important to understand how to properly insulate the roof of a house in order to avoid mistakes that will ultimately lead to damage to wooden structures.

The most popular insulation in private housing construction is mineral wool. This is an easy-to-install, non-flammable material that can be purchased at a low price. But the structure of the wool itself promotes the accumulation of moisture, which causes a significant decrease in the thermal insulation properties of the material, and also, over time, provokes rotting of the elements of the rafter system. Thus, when creating insulation, it is important to provide proper ventilation and steam and waterproofing of the roofing pie.

Installation of a pitched roof heat insulator is carried out from the attic side during the construction or repair of the roof. If repair work is being carried out, before laying the insulation, it is necessary to check the condition of the rafters - rotting elements must be replaced with new ones. It's also worth processing everything wooden structures fire-retardant composition.

The pitched roof pie includes:

- finishing roof covering;

- hydrobarrier (layer of waterproofing material);

- heat insulator;

- vapor barrier;

- interior decoration (optional).

Proper roof insulation requires high-quality air exchange, for which it is necessary to create air gaps between:

- under-roof waterproofing and roofing;

- insulation and water barrier;

- vapor barrier and internal lining (if provided).

Air circulation (free inflow and removal) is ensured by special vents, one of which should be located in the roof overhang, and the second under the ridge.

Materials for thermal insulation of pitched roofs

Roof insulation technology involves the use various materials. The most popular heat insulators include mineral wool and glass wool (in slabs or rolls), slab polymer materials– polyurethane foam, polystyrene foam. The principles of their installation are similar, but it is worth noting that installing slab material is much simpler and more convenient.

As waterproofing, roofing material or a waterproofing membrane is usually used, which is impermeable to water, but capable of removing moisture from the insulation. The vapor barrier layer can be made of:

- roofing felt;

- polyethylene film;

- glassine;

- foil materials laid with foil towards the attic.

To create a roofing pie with high functional characteristics, it is recommended to use a special vapor barrier membrane to create a vapor barrier: it removes condensation outside from the insulation and does not allow steam and moisture to pass into the roofing pie.

Stages of work on insulating a pitched roof

The roof insulation scheme is quite simple. First of all, you need to measure the distance between the rafters. The slabs of cotton wool insulation should be cut according to the results obtained, adding 1 centimeter. This will allow you to fasten the heat insulator between the rafters. This stage of work is greatly simplified if the roofing system is initially designed and installed based on the use of slab insulation boards of a certain width.

If there is no waterproofing between the rafters and the already installed roofing, you should first secure a water barrier. The membrane should envelop the rafters; it is most convenient to fasten it with a construction stapler to the rafters themselves and to the roof sheathing in the openings between them. The waterproofing must be installed under the eaves at the bottom of the roof to ensure moisture drainage. It should be taken into account that with this method of fastening the hydrobarrier, the insulation must be installed without the necessary air gap. For this reason, it is recommended to use a superdiffusion membrane as a waterproofing material.

If there is a waterproofing layer under the roofing, nails are placed on the rafters in increments of about 10 cm. The nails should be located at a distance of 3-5 cm from the waterproofing layer. It is necessary to stretch a polyethylene thread or cord between the nails, tamping them to the end. This will help create an air gap between the hydrobarrier and the insulation. If the heat insulator is planned to be fixed with a cord, and not with lathing for internal cladding, nails must also be driven along the outer edge of the rafters.

If, when deciding how to insulate the roof of a house, you chose cotton slab insulation, then the prepared elements must be slightly compressed and inserted between the rafters. When using stiffer foam boards and similar materials, it is important to accurately adjust them to size so that the slabs fit tightly into the opening. It is recommended to carry out insulation in two layers. If you have to mount not solid sheets into the opening, but narrower fragments, joining them along the length or width, you need to make sure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to install two layers of insulation, additional timber is nailed to them.

If, when deciding how to insulate the roof of a house, you chose cotton slab insulation, then the prepared elements must be slightly compressed and inserted between the rafters. When using stiffer foam boards and similar materials, it is important to accurately adjust them to size so that the slabs fit tightly into the opening. It is recommended to carry out insulation in two layers. If you have to mount not solid sheets into the opening, but narrower fragments, joining them along the length or width, you need to make sure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to install two layers of insulation, additional timber is nailed to them.

The heat insulator is fixed between the rafters using a stretched cord secured to pre-filled nails. Or, as a fastening, a lathing made of slats is used, intended for mounting the interior lining of the room. The slats are nailed to the rafters in increments of 30-40 cm. In this case, the vapor barrier is stapled to the rafters before installing the sheathing: the thickness of the slats allows you to create the necessary air gap between the vapor barrier and the sheathing.

When installing a vapor barrier, special attention is paid to the tightness of the layer. The panel is laid with an overlap of at least 10 cm, the joints should be taped with adhesive tape in two layers. It is necessary to install the vapor barrier around the chimney and at the junction with the walls as efficiently as possible. At the final stage, the sheathing is installed using wood-based or plasterboard boards.

How to insulate the roof of a house correctly: video, insulation diagram, methods

Find out how to properly insulate the roof of your house. Look at the video on how to insulate the roof of a house using various schemes, methods and types of insulation

How to properly insulate the roof along the rafters?

There are frequent cases when owners of private houses want to turn an ordinary attic into an attic with insulation for the roof. Such changes are directly related to the modification and insulation of the existing roof.

Waterproofing is laid in the openings between the rafters

In addition, roof insulation oriented towards any system will be associated with providing ventilation and installing high-quality vapor and waterproofing.

1 What is the best way to insulate the roof along the rafters?

Today, the most common method of insulating pitched roofs is rafter roof is one in which thermal insulation is provided by foam plastic.

In this case, you need to lay the insulation to the rafters on a pitched roof following a certain system.

The insulation between the rafters, which ensures the stability of the roof structure, can be fixed in one of the two most common ways, and you can use mineral wool.

Despite this, many rightly believe that it is better to insulate the rafter structure of a pitched roof with foam plastic to insulate the attic of a private house.

It should be remembered that when insulating rafters on a pitched roof with foam plastic, its fastening will be oriented at a certain distance.

Installation of insulation must be carried out from the bottom up

There are now a lot of materials for insulating rafters and roofs in general. Most people use foam plastic to insulate roofs, and especially the rafter part.

Providing thermal insulation of roofs and its rafters with foam plastic has a number of undoubted advantages, however, you should find out what other materials and their types can be used to form reliable thermal insulation of the roof, because in addition to foam insulation there are several more equally proven and reliable options.

It is worth noting that many are inclined to believe that thermal insulation of roofs with foam plastic is a cheap and reliable option, while mineral wool is significantly inferior to the presented method.

To understand what methods of improving the roof and insulating the roof using polyurethane foam will be the most effective, you need to know how this work is carried out and what materials for roofs are most in demand.

Indeed, along with the method based on foam insulation, innovative roof thermal insulation technologies such as spraying polyurethane foam are offered.

In order to figure out which materials and their types to use to ensure the heat resistance of the roof, you should consider each of them individually.

2 Features of the materials used

Mineral wool, according to many, is the immediate leader among those materials that can be used for roof insulation.

She has whole line advantages compared to previously announced polystyrene foam. Properties such as non-flammability and high level The fire safety of roofs when used speaks for itself.

The presented material has a high degree of elasticity and can be laid on the roof between the rafters with orientation at any distance.

Subsequently, the mineral wool retains its original shape, and the distance between the slab positions does not change.

Proper roof insulation

Since during installation there are no gaps between the beams and the presented building material between the elements on the roof, its use is the most relevant. The main advantages of this material for roof modernization include:

- Low cost;

- Public accessibility is like insulating an attic from the inside;

- Ease of installation;

- Good thermal insulation qualities.

The main disadvantage of mineral wool is its increased degree of hygroscopicity. The material actively absorbs moisture into its structure, which leads to it getting wet.

The distance between the fibers of the substance changes and the product rapidly loses its thermal insulation properties by 60-80%.

Therefore, before insulating with cotton wool, you need to take proper care of its waterproofing.

Expanded polystyrene is now gaining quite high popularity, and, according to many experts, it is absolutely undeserved.

We nail nails along the rafters at a distance of 7-8 cm from the waterproofing film

The fact is that strengthening roofs using it is quite fraught with serious consequences in the event of a sudden fire of the material.

When ignited, the product begins to spray fiery drops in all directions. During installation, over time, the structure of the material is subject to crumbling, and the distance between it and the roof increases, which leads to a deterioration in the heat-insulating properties.

In most cases, the foam is hidden under a layer of plaster or screed. Extruded polystyrene foam is essentially the same modified polystyrene foam.

It is used in places where the fastening requires a high degree of rigidity. This material can also burn, but does not support the combustion process.

It is perfectly capable of maintaining its original shape, and its structure is not subject to crumbling during installation. The undoubted advantages of extruded polystyrene foam are expressed in:

Roof rafter system

- Moisture resistance;

- Durability;

- Light weight;

- Strength;

- Hardness;

- High thermal insulation performance.

Polyurethane foam began to be used for roof insulation relatively recently. This material is presented in the form of gas-filled plastic.

Filling is carried out using a special unit, and the undoubted advantage is the complete absence of cracks and gaps.

Submitted by construction material It is not flammable, has a relatively low weight and holds its shape well.

Spraying can be carried out at a distance equal to the gap between the rafters, which helps remove cold bridges.

A significant drawback is its pronounced vapor permeability. Because of this, you need to take good care of creating supply and exhaust ventilation.

Laying insulation between rafters

Ecowool, also called cellulose wool, also began to be used for insulation relatively recently.

It is not without its advantages: it does not burn, is environmentally friendly, is lightweight and can be blown into all the cracks. In addition, the presented material is not able to absorb moisture.

2.1 Nuances of installing insulation

This technology will be discussed using the example of laying mineral wool in a layer of 250 mm. All types of work related to the presented method of roof insulation are most rationally performed in the early stages of building a house.

Otherwise, the attic support will need to be removed along with the outdated roofing material.

After the rafter structure has been completely assembled, but the installation of roofing material has not yet begun, it is necessary to ensure a high level of waterproofing of the roof.

For this purpose, a waterproofing superdiffusion membrane is laid on top of the installed rafters, as when insulating the roof of a building with mineral wool.

It is important not to confuse its sides. This is due to the fact that one of the sides is not capable of passing water, and the other is not reverse side does not allow steam to pass through.

Insulation and waterproofing of roofs of complex shapes

The membrane must be laid so that the outer surface is on the side that is characterized by its high degree of moisture resistance.

Installation begins from the eaves overhang located below and moves to the top of the roof.

The overlap should be oriented at a distance of 10-15 cm, and the joints should be glued using special construction tape.

It is forbidden to lay the waterproofing film under tension. This is due to the fact that when winter comes, it can shrink, which will lead to damage in the places where it is secured.

Based on this, the material is spread with a slight overhang, which is 2 cm per 1 m. The film is attached to the rafters using special staples and a construction stapler.

If such a tool is not available, then you can use galvanized nails equipped with a wide head.

The next stage involves the formation of a ventilation gap. Excess vapor contained in the insulation material will subsequently escape through it.

On top of the waterproofing layer, a sheathing is made of wooden slats, the thickness of which may depend on the width of the ventilation gap itself.

Roof insulation along rafters

The slats are secured using galvanized self-tapping screws. After this, roofing material is installed on top of the sheathing.

2.2 How to lay insulation between the rafters?

At the beginning of the installation process, you should unpack the mineral wool and let it sit for some time so that the material takes the shape required for work. Next, the canvas or slabs are cut into the sections required for installation.

In this case, the parameter for the width of the mineral wool sheet must exactly correspond to the distance between the beams, to which an additional 20-30 millimeters should be added in order to create tension.

Mineral wool can be cut using a regular construction knife. However, it is worth remembering that all work must be performed with gloves, a respirator and thick clothing in order to avoid contact of microparticles with unprotected areas of the skin.

After this, the fabric of the product is pushed into the space between the rafters. In the process, the edges of the material that is located near the rafters are slightly bent.

To do this, you need to lightly press on the middle section of the canvas, as a result of which the edges will straighten out. At this stage, the roof insulation process can be completed.

Insulation of a metal roof

As a result, rafters made of wood and the insulation between them will be reliably protected from the harmful effects of moisture that can penetrate through damaged areas of the roof.

WITH inside the insulation will be reliably protected from the effects of steam emanating from the room, and the entire presented structure will be repairable.

If there is a need to inspect the condition of the rafters, then first you will have to dismantle the sheets of plasterboard, then remove the sheathing and vapor barrier film, and then reinstall them.

If you need to insulate the roof in an old house, and there is no desire to remove the already laid roofing material, then you can attach a waterproofing membrane to the inside of the attic.

In this case, you will need to wrap the surface of the rafters with a membrane and wrap it inside the space between them.

You will need to lay a layer on top insulation material. Insulation of a soft type roof is carried out using the same technology that was described above.

Roof insulation from the inside

The difference is that the sheathing, which forms the gap between the waterproofing membrane and the roofing material itself, is supplemented with a layer of moisture-resistant plywood. A soft roof is attached on top of a layer of such plywood.

2.3 Roof insulation under rafters

The scheme, thanks to which insulation is produced under the rafters, is used in residential buildings quite rare.

As a rule, it is implemented during the construction of structures industrial type, which are equipped with reinforced load-bearing elements made using metal.

The presented diagram can be used in case of reconstruction of a construction site.

At the same time, during the work process it should be taken into account that the area of the internal space of the room will be significantly reduced.

This option can also be used in cases where increased requirements are placed on ventilation.

This applies to rooms with a high degree of humidity. When insulating roof slopes using this scheme, the importance of the thermal insulation material is lost.

Insulation of the attic roof slopes between the rafters

This is due to the fact that due to the high degree of openness, the vapor barrier layer may be damaged.

Premises with this type of insulated roof must be frequently ventilated, or special roof fans with high power must be installed in them.

Roof insulation along rafters: installation, how to secure

Roof insulation along rafters - description of technology. What is the best way to insulate the roof along the rafters?

How to insulate a roof, choosing materials for a pitched and flat roof

In order for the roof to perform its functions efficiently and serve for a long time, it must be insulated. There are a lot of materials and methods for installing a heat-insulating layer, and the choice suitable technology always done individually. This article will discuss how to properly install insulation on the roof of a private house.

The need for roof insulation

Of course, the final decision about whether the roof needs to be insulated is made by the owner of the house - but before that, you need to weigh all the pros and cons. The latter include additional costs for arranging the roof and the effort required to install the heat-insulating layer.

However, the financial expenses and efforts made will pay off in the future. The main advantage of roof insulation is that after installation, the level of heat loss of the entire building is reduced by an average of 15%. If the under-roof space is not intended to be used as a residential space, then the roof itself does not need to be insulated - the thermal insulation of the roof of the house in this case will be mounted on the attic floor or the ceiling of the living premises. To prevent the structure from rotting, you will need high-quality ventilation roofs.

Roof insulation will be most relevant when arranging a residential attic, especially if the building is located in a region with a harsh climate. In such cases, if the attic will be used all year round, you will have to pay special attention to the issues of its insulation and heating. Less stringent requirements are imposed on the insulation of summer attics.

How to properly insulate a flat roof

When insulating a flat roof, you need to take into account that thermal insulation can be on both the inside and outside. It is advisable to start with external insulation, and after the first winter decide whether it makes sense to insulate the roof along the rafters from the inside.

A flat roof roofing pie consists of:

- Vapor barrier layer;

- Insulation layer;

- Waterproofing layer;

- Bulk layer.

For arrangement external thermal insulation Most often, basalt mineral wool is used, which is optimally suited for these purposes. However, you can choose from any type of rigid insulation - for example, expanded polystyrene would be a good option. It is also worth remembering that roof coverings that are prone to fire cannot be insulated with polymer heat insulators.

Insulation of a pitched roof

Thermal insulation of a pitched roof is installed on the rafter system. Before laying insulation on the roof, it is necessary to design it in advance in order to avoid installation errors.

A pitched roof consists of the following elements:

- Roofing;

- Waterproofing layer;

- Thermal insulation;

- Vapor barrier material;

- Interior finishing (optional).

Mineral wool is most often used as a thermal insulation material, which has high performance characteristics and is relatively inexpensive. The main disadvantage mineral insulation is the ability to absorb moisture, due to which the thermal insulation properties are lost over time. In addition, the presence of moisture under the roof leads to the gradual destruction of wooden parts.

To compensate for the described disadvantage, the structure must be supplemented with ventilation, hydro- and vapor barrier. The insulation itself on the roof of the house is laid on the underside of the roof during its arrangement or repair. If we are talking about repairs, then damaged wooden elements should be replaced, and new ones are treated with protective compounds before installation.

In addition, for effective insulation and reliability, the roof must be well ventilated, so it is necessary to install ventilation ducts between:

- A layer of waterproofing and finishing coating;

- Thermal insulation and waterproofing layer;

- Vapor barrier material and internal lining.

Materials for insulating pitched roofs

Various materials can be used to insulate the roof, the most popular of which are:

The characteristics and features of the materials differ, but they all adequately protect the roof from temperature effects. It is only worth noting that it is best to select materials produced in the form of slabs - they are much more convenient to install.

To construct a waterproofing layer, ordinary roofing material or a special waterproofing membrane is most often used, which does not allow water to pass through, but ensures the removal of moisture from the heat insulator. When installing waterproofing, you need to ensure that the tightness of the material has not been compromised.

However, if we are talking about a high-quality vapor barrier layer, then the best option would be a vapor barrier membrane, which works on the principle of one-way moisture transmission - condensate is removed from the insulation and does not enter internal cavities roofing pie.

Algorithm for roof insulation - how to lay thermal insulation

Installation of a roof with insulation comes down to the following sequence of actions:

- First, the installation step of the rafter legs is measured. The heat-insulating material slabs are cut in accordance with the obtained dimensions, but 1 cm is added to them - this will allow the insulation to stay in place on its own. You can simplify this stage of work when installing a new roof by calculating it so that the distance between the rafters corresponds to the width of the insulation boards.

- A waterproofing layer must be installed in the space between the rafters and the finishing coating. The membrane must be attached to the rafters so that it envelops them. Can be used for fixation construction stapler, with which the waterproofing is attached to the rafters and sheathing. Waterproofing material must be brought to eaves overhangs so that the collected moisture goes beyond the roof. The described method of fastening does not allow for proper ventilation, so only a special waterproofing membrane should be used as a material.

- If waterproofing is already installed under the upper part of the roof, then nails are driven into the rafters every 10 cm so that the distance between them and the membrane is at least 3-5 cm. The driven nails allow you to stretch a cord along the line of which the air gap will pass in the space between waterproofing and thermal insulation material. If the insulation itself is attached using a cord, then the nails will also need to be hammered along the outside of the rafters.

- When using insulation materials produced in the form of slabs, installation is reduced to inserting them into the space between the rafters (naturally, they will have to be compressed a little so that they fit into the gap). Before properly insulating the roof, more rigid materials must be carefully adjusted to fit the gaps in the rafter system. For maximum efficiency, it is worth installing two-layer insulation.

- When installing narrow fragments that require joining along one of the planes, you need to make sure that the joints of the first and second layers of thermal insulation do not coincide with each other. The thermal insulation layer should not extend beyond the rafters, and if this happens, then additional timber will have to be placed on the rafters.

- To attach the insulation, a cord stretched between nails or a lath made of slats can be used. These slats need to be nailed to the rafters at a distance of 30-40 cm from each other. In this case, the vapor barrier layer must be attached before the sheathing is installed - due to the thickness of the slats, an air gap is provided.

- When installing a vapor barrier, you need to make sure that the material is installed hermetically. To do this, the joints must be covered with two layers of adhesive tape. Special attention you need to pay attention to the points where the material connects to the wall and the chimney. When all structural elements are installed, you can proceed to the final stage - installation of the sheathing.

Roof insulation is a very important part of the structure, which allows you to increase the thermal efficiency of the roof. Knowing how to properly install insulation on a roof and high-quality performance of all work will allow you to create a reliable and high-quality structure that will perform its functions throughout the entire period of operation.

Roof insulation: how to properly insulate the roof along the rafters, how to lay insulation, installation of thermal insulation, how to lay

Roof insulation: how to properly insulate the roof along the rafters, how to lay insulation, installation of thermal insulation, how to lay

Every owner of a private home faces roof insulation work. Those who are doing this work for the first time will face a long process of familiarization with different technologies and studying properties modern materials. The task of roof insulation is to create a cake from insulation and waterproofing films. Regardless of the type of roof structure, the durability and efficiency of insulation is determined by the correct choice of materials and compliance with the sequence of laying each layer of the roofing cake.

Why do you need to insulate your roof?

A third of a home's heat loss occurs through the roof. Therefore, high-quality roof insulation primarily saves money on heating the house.

The infrared photo clearly shows that there is no heat loss through the insulated roof

Insufficient waterproofing and insulation of the under-roof space leads to the formation of dampness. She penetrates load-bearing elements roof frame, resulting in a reduced service life.

Insulating a pitched roof allows you to turn the attic into a full-fledged living space.

Common materials for roof insulation

All materials used for roof insulation are divided into two types:

- Cotton (or fibrous). This group includes basalt (stone) wool, glass wool, and slag wool. Products of this type have different characteristics of rigidity, density, crease resistance and are produced in the form of rolls or plates. Cotton insulation is considered non-load-bearing materials.

- Foam. These materials are made from foamed polymers and are available only in the form of slabs. They have high rigidity and are classified as load-bearing materials.

Features of cotton materials

Cotton insulation has the ability to transmit moisture vapor, but should not get wet. To prevent water condensation from being retained in the thickness of the material, its fibers are coated with a water repellent. Thanks to this, moisture is not absorbed by the fibers, but flows out or is ventilated by air currents.

Mineral wool

Due to its vapor permeability, mineral wool is considered the best material for insulating roofs with wooden rafters, as it promotes the natural exchange of moisture between wood and air.

Basalt wool is produced in the form of slabs, which are conveniently mounted in cells between the rafters

Basalt wool is produced in the form of slabs, which are conveniently mounted in cells between the rafters But the ability to transmit moisture vapor also has a negative side: it is necessary to use a waterproofing film to protect the insulation from the roof side and a vapor barrier film to protect from warm humid air from the residential premises.

On waterproofing film Condensation will accumulate. If it lies close to the cotton insulation, then moisture will penetrate into its thickness. This will lead to the insulation getting wet and mold appearing in it. Therefore, when using conventional vapor-proof films for waterproofing, it is necessary to leave a gap of 2–3 cm on each side between the insulation and the film. This space is called the ventilation gap. After condensation, moisture will be removed from the surface of the waterproofing membrane natural circulation air.

Instead of conventional waterproofing films, you can use a superdiffusion membrane. This material allows you to do without a ventilation gap, which will simplify the process of installing insulation. Such a film will save space and allow you to lay insulation over the entire height of the rafter beam, completely filling the cells.

Basalt insulation

Mineral wool often means basalt insulation. However, due to the special arrangement of the fibers, basalt wool has higher thermal protection and is practically not susceptible to the formation of fungi and mold. This dense material does not cake, does not compact, and is not subject to combustion over time.

Basalt wool retains heat better and does not react with oxygen, which usually causes mold to form.

Basalt wool retains heat better and does not react with oxygen, which usually causes mold to form. Basalt wool It is most often used to insulate pitched roofs by installing it in the cells of the rafter structure. The advantage of all cotton materials with this installation method is the ability to completely fill the cells without cracks or cold bridges.

This material has also become widespread by analogy with basalt insulation. It is available in both rolls and mats different thicknesses(up to 150 mm). Therefore, you can always select the material in accordance with the configuration of the roof frame cells to minimize waste during cutting. But in terms of density, thermal conductivity and compression resistance, glass wool is inferior to basalt insulation.

Glass wool has worse thermal insulation properties, but is cheaper

Glass wool has worse thermal insulation properties, but is cheaper The main argument that allows glass wool to compete with basalt insulation is its low price. Therefore, many craftsmen prefer this material, despite the well-known ability of glass wool to slide down the slope over time, forming cracks and severely irritate the skin when working with it.

Slag wool

Made from blast furnace slag. Of all cotton materials, it has the widest operating temperature range (up to 300 o C). Slag wool also has the greatest hygroscopicity, so it is not used for insulating facades.

Slag wool absorbs water well, so it must be carefully protected with a waterproofing coating

Slag wool absorbs water well, so it must be carefully protected with a waterproofing coating Slag wool has the most “dirty” base, therefore it is not recommended for use in residential premises. This material is usually used for insulation industrial buildings and pipelines.

Plate materials

Different types of polymers are used to make board materials. These are polystyrene, foam plastic, polyurethane.

An important characteristic of slab materials is rigidity and vapor permeability. The technology for using insulation in a warm roof pie also depends on this. The ability to transmit moisture vapor depends on the method of molding polymer foam boards in production:

To insulate the roof between the rafters, slab foam materials are not used, since it is difficult to cut the material precisely according to the cell dimensions. The inevitable cracks will become bridges of cold. In addition, if the rafters are not mounted taking into account the dimensions of the material, a large amount of waste will appear during cutting.

Pitched roof insulation technology

A pitched roof can be insulated in the following ways:

- Installation of insulation between rafters.

- Formation of a continuous layer of insulation on top or under the rafters.

- Combined method.

Insulation between rafters

The easiest way is to install insulation with single-layer ventilation using a superdiffuse membrane. For this method, insulation is purchased, the thickness of which is equal to the depth of the cell:

Superdiffusion membrane is attached closely to the insulation

Superdiffusion membrane is attached closely to the insulation If you have an old waterproofing film and you plan to use a film with low vapor permeability (microperforated film) for padding underneath, then the gap between the insulation and the film should be on both sides. To do this, it is necessary that the panel is not completely recessed into the cell, but with a distance of 2–3 cm from the edge. The same gap must be left on the attic side. The thickness of the insulation should be 5 cm less than the depth of the cell. The support for the panel can be padded slats around the perimeter of the cells or pieces of wire stretched over nails:

- A thin strip (2 cm) is placed along the upper edge of the cell, and nails are driven in at a distance of 2 cm from the upper edge of the beam.

- Nylon threads or wire are wound crosswise around the nails. Now, when laying the insulation into the cell, the necessary gap will remain between it and the film.

- Exactly the same operation is performed after installing the mineral wool panels. The threads on the bottom side will prevent the material from sagging or moving in the cell.

To create a ventilated gap, the thickness of the insulation must be less than the depth of the cell between the rafters

To create a ventilated gap, the thickness of the insulation must be less than the depth of the cell between the rafters Insulation with foam slabs must be done in two layers. This is done in order to cover the gaps at the joints. In this case, the joints of the slabs of the second row should be shifted relative to the joints of the first row.

It is necessary to select the thickness of the foam insulation so that it does not extend beyond the rafters. If the material (or two layers of it) protrudes from the cells, the rafters must be extended with timber.

Video: laying mineral wool between rafters

The disadvantage of insulation between the rafters is the presence of cold bridges along the perimeter of the cells. Therefore, many owners use combined insulation methods, additionally installing a layer on top or under the rafters.

For insulation over rafters, foam boards that have sufficient rigidity are ideal. This material copes well with the load that it will experience under the roofing material, so most often in new buildings a continuous layer of insulation is mounted on top of the rafters from the outside. This is much more convenient than screwing panels from the inside. In addition, you can save interior space. And if you do not combine the laying of slabs with insulation between the rafters, then the open parts of the timber inside the attic will be original element interior

Foam insulation is not afraid of moisture, so there is no need to waterproof the under-roof space