The whole truth about induction heating: is the game worth the candle? Homemade induction heating boilers Do-it-yourself induction boilers for home heating

Many residents of private and apartment buildings, trying to save on electricity, are looking for the most profitable option to heat their homes.

That is why people are increasingly installing induction boilers with their own hands.

The main advantages of such an installation are that it is economical and durable, and you can mount it yourself.

This design can be assembled by hand

Boiler device

Before proceeding with the assembly, it is necessary to understand the principles of operation of the device. It should be noted right away that they are similar to heating elements, which are responsible for converting electrical energy into heat.

Do-it-yourself installation of an induction electric boiler does not require a complete replacement of the heating system, since it works on the principle of an electric inductor, which includes two windings:

- primary;

- secondary.

The primary circuit is engaged in the conversion of electrical energy into eddy current, but the magnetic field created by this process goes to the secondary winding, where heat is generated.

In this video you will learn how to make an induction boiler with your own hands:

The main element in the device is the body. It consists of the following parts:

- core;

- outer case;

- electrical insulation;

- thermal insulation.

In industrial devices, the winding is cylindrical. A self-made induction boiler has a toroidal winding. It is assembled from copper wire. The body is surrounded by ferromagnetic steel with a thickness of about 1-1.5 cm. All this can significantly reduce the weight of the unit and increase efficiency.

If we compare a home-made device with any other equipment that runs on gas or liquid fuel, then we can distinguish it the following nuances:

- the heat carrier has double heating;

- faster heating of the room;

- minimum indicator of inertia;

- due to magnetic induction, scale does not form;

- The device does not need to be cleaned.

It is also worth noting that the coolant in a do-it-yourself induction heating boiler receives about 97% of the heat energy. This increases productivity and reduces energy costs.

This is all you need to make it.

This is all you need to make it. Installation work

Initially, you need to prepare a drawing. It is easiest to make an induction boiler with your own hands, having a heating system diagram at hand. If everything is ready, then you can start the workflow. In this case, any special equipment or too expensive material for manufacturing is not required. It will be enough to have a minimum experience with an inverter-type welding machine. All actions are performed as follows:

- First you need to cut the stainless wire into several pieces. Their length should be about 5 centimeters, diameter - 7 millimeters.

- To make the case, you will need a plastic pipe with a diameter of 50 mm.

- Now you need to cover the bottom of the prepared pipe with a metal mesh. It is desirable that it be with small cells, then pieces of stainless steel cannot pass through them.

- Fill the body with existing wire. Then tightly close the second opening of the pipe using the same mesh.

- The next step is to wind the copper wire around the middle part of the body, making about 90 turns. This must be done as tightly as possible.

- Now you need to connect the tie-in adapter to the structure. You can use both plumbing and heating systems.

After completing these steps, the following should happen: water passes into the heater through the first adapter, heats up quickly, and then enters the radiators through the second adapter, thereby heating the entire dwelling.

Thus, it is quite easy to make induction heating of a private house with your own hands. Moreover, this design does not require a separate boiler room. To do this, you just need to cut a piece of pipe near the entrance to the radiator and weld a home-made heater to this place.

After that, you need to correctly connect the finished coil to the 18-25 A inverter, and also fill the system with coolant. The main thing is not to connect without a thermal carrier, since the plastic shell of the device will simply melt, and all previously performed actions will be in vain. Also, do not forget about grounding, it will allow you not to worry about safety.

Boilers of this type are easy to assemble, install and further operate. There are rules that will help you easily equip in the house do-it-yourself induction heating:

- diagrams and drawings are necessarily used during work, this is the only way to get boilers that will function efficiently and smoothly;

- home-made units can only be used in closed heating systems, when air circulation operates due to the operation of the pump;

- the wiring of the heating system, working in conjunction with the device, is made exclusively from a plastic or propylene pipe;

- to prevent possible troubles, it is necessary to install the heater correctly (it should be at a distance of 30 centimeters from the walls and 80 centimeters from the surface of the floor and ceiling).

In addition, it is required to equip the pipe with a special blast valve, with which it will always be possible to remove excess air from the heating system, normalize pressure and provide optimal working conditions.

Boilers of various types are used in modern water heating systems. If we consider electric water boilers, then they are divided into three main categories according to the method of heating the coolant:

Electric water boilers in the heating system

Classification

- TENovye. In such boilers, water or other liquid is heated with the help of TENs - special heating elements.

- Electrode. The heat carrier is heated by means of electrodes. Since water is a conductor of electricity, an electric potential is created in the boiler chamber between the two electrodes, and as a result, the water is heated.

- Induction. The design of this boiler for heating a private house resembles a transformer, in which a metal core acts as a heater, which is located in a magnetic field. This is a relatively new type of electric boilers, which is becoming more and more popular every day.

Industrial induction boiler

Advantages

Each type of electric boiler has its own advantages and disadvantages. If we consider induction boilers, then we can distinguish the following advantages:

- Water in such boilers heats up much faster compared to other boilers. This is due to the fact that no time is wasted on heating the heating elements themselves or the electrodes.

- Such boilers have an efficiency almost like that of a transformer: many times more than other types of boilers. Moreover, it does not change throughout the life of the product.

- During the operation of the heater, a slight vibration occurs, so less scale is formed in such boilers.

- The service life of such a factory-made device is approximately 20-30 years, since it has very few parts that can break.

Flaws

Of the disadvantages of this device, two can be distinguished: cost - such devices are quite expensive today, but it can be assumed that in the future the price will fall. Moreover, a good home master will be able to make such a device on his own, reducing the cost of the finished product at times, a magnetic field is formed near such a boiler, the effect of this field on a person has not been fully studied, therefore it is not recommended to install it in residential premises.

Having considered all the good and bad sides of the operation of this type of boiler, you can decide to install such a device in the heating system of a private house. If the head is in place, and you don’t want to spend extra money on a purchase, then you can make it yourself.

DIY manufacturing

Before you make such a device, you must first understand how it works. In fact, induction furnaces have existed for a long time and until recently were used in production for melting metals in a magnetic field. This furnace works like a transformer: a current of high frequency, about 1 MHz, is supplied to the primary winding. The second is short-circuited, the role of the core here is played by a melted piece of metal. That is, if a dielectric, for example, plastic, enters a magnetic field, then it does not affect it in any way, the metal will immediately melt. This is what distinguishes such furnaces from heating elements, in which everything is melted.

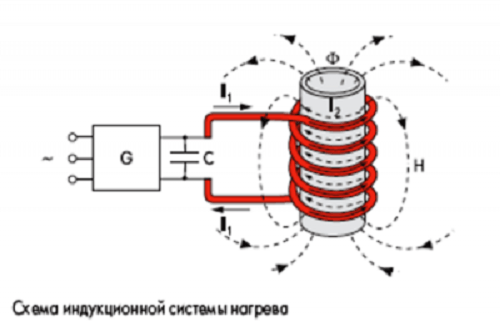

The principle of operation of such a boiler is shown in the figure below. The arrows show the movement of magnetic fields inside and outside the winding.

The principle of operation of the induction boiler

In the manufacture of an induction boiler, you can go in two ways: the core is a piece of pipeline, in the middle of which there is a metal core of wire segments. A radial or toroidal winding is wound around the pipeline, through which an alternating current of high frequency is passed, the boiler is a container for water, which is heated by an industrial induction cooker.

To manufacture a device of the first type, you need to take a piece of pipe with a diameter of 50 mm, in which an adapter is soldered on one side, and inside the passage is closed with a pre-cut circle from a metal mesh. Then, pieces 7 cm long are cut from a metal wire with a diameter of 5-8 mm. These segments are laid in a pipe and covered with a mesh so that they do not enter the heating system. On the other hand, an adapter is soldered to the pipeline for inserting the boiler into the heating system. 90 turns of copper wire with a diameter of 1.5-1.7 mm are wound on this pipe. In this case, it is necessary to ensure that the turns are evenly spaced and as close as possible to each other.

For winding, you need to take a new wire, since with the old wire the product may not last long.

The figure shows a variant of such a boiler.

Plastic pipe boiler

To power the boiler, you can use either an induction hob or a welding inverter. When using a tile, the winding is connected instead of the output coil of the device. It is better to use a welding inverter with smooth current control. If a welding inverter is used, the output current is selected empirically, so that the winding does not overheat, and at the same time the boiler works well.

It is possible to connect a boiler of this type only if there is water in the system, since without a coolant such a boiler will simply melt.

For the manufacture of a different type of boiler, first of all, it is necessary to purchase an induction cooker of the required power. After that, you can begin to manufacture a tank for the boiler. The tank is made in the size of 600 × 500 × 50 mm. For this, a square pipe 5 cm wide is taken. 12 pieces 500 mm long are cut from it. 10 pieces are welded together with walls to make a comb with dimensions of 500 × 500 × 50 mm. In the two remaining pieces, one wall is cut out and welded with their cut side to the outlets of the comb pipes. After that, four 5 × 5 cm squares are brewed, and the tank is ready. Inlet and outlet pipes are welded diagonally on both sides. A tile can be screwed to the back wall of the resulting container so that the control panel protrudes from the tank.

Before attaching the tiles and connecting the boiler to the heating system, check the welded structure for leaks. To do this, one outlet must be drowned out, and in the other - water must be supplied under pressure. If there are no leaks at a pressure of 5 atmospheres, then you can work on, if there is, you need to digest it.

The figure below shows one of the options for such a boiler, where the welded structure is visible in the foreground, from behind which the control panel of the induction furnace peeks out.

Boiler with induction furnace

When operating devices such as an induction boiler, you need to know the following:

- Such boilers must be used in forced circulation water heating systems, since water must constantly circulate in the boiler.

- It is better to install the boiler in non-residential premises, since a magnetic field forms around it, which can adversely affect the human body.

- A relief valve must be present in the heating system, because if the pump fails, the core on the boiler will simply break.

- The distance from the floor and ceiling of the house to the boiler must be at least 80 cm, and from nearby objects - 30 cm.

- The welding inverter must be grounded to avoid electric shock.

- An RCD must be present in the inverter connection system, which will prevent accidents when working with the boiler.

Do not install the boiler in a residential area, as it is an unsafe device for humans, as it emits a harmful magnetic field, and is also an electrical and explosive device.

Induction boiler in the home heating systemVideo

Heating boiler. Video

You can learn about the features of installation and operation of an induction heating boiler from the video below.

In conclusion, we can say that boilers of this type are still an innovation in heating systems, but they have already proven themselves quite well in the heating equipment market. In terms of efficiency, they are inferior only to infrared heaters. However, unlike infrared heaters, induction boilers can be made independently, which makes them more accessible to a wide range of consumers. Moreover, if there is a choice between heating elements and induction, then, most likely, it is necessary to make a choice in favor of the latter, due to their obvious advantages. In terms of reliability, energy efficiency, economy, they are not inferior to any heating element boiler.

In contact with

Would you like to furnish your home with efficient yet cost-effective heating? Then be sure to pay attention to modern induction boilers. Such units are characterized by high performance and at the same time have an extremely simple design, so you can easily handle the assembly of an induction heating boiler with your own hands. The operation of the equipment in question is based on the use of induction electrical energy.

Such boilers are absolutely safe and environmentally friendly. During their operation, no by-products are released that can harm a person and the environment.

By design, such boilers are a kind of electrical inductors, which include two short-circuited windings.

So, the internal winding is responsible for converting the incoming electrical energy into special eddy currents. An electric field is formed in the unit, which subsequently enters the secondary coil. The latter simultaneously performs the functions of the heating element of the heating unit and the boiler body.

The secondary winding is responsible for transferring the generated energy directly to the heating medium of the heating system. Special oils, non-freezing liquids or pure water are used as a heat carrier in such installations.

The internal winding of the heater is exposed to electricity. As a result, some voltage appears and eddy currents are formed. The generated energy is given to the secondary winding, after which the heating of the core begins. Upon reaching the heating of the entire surface, the coolant will begin to give heat to the radiators, and they to the heated rooms.

Is it rational to assemble the boiler yourself?

Induction heating boilers have the simplest design, there are no difficulties with their assembly. However, you will definitely have to at least carefully study the proposed instructions and make an effort to properly assemble a quality unit.

The reward for your efforts will be efficient and financially profitable heating equipment. To assemble the boiler, you do not need to buy any expensive components - all the necessary elements are sold in ordinary construction, household and other specialized stores.

With proper assembly and proper handling of the finished unit, it will quietly last 20 years or more. The main thing is to do everything in strict accordance with the instructions.

Super-complex tasks are not set for you, and it is almost impossible to make any critical mistakes when assembling an induction boiler according to the instructions.

Assembly of a simple induction boiler

To assemble an induction boiler, you do not need to use any difficult-to-handle tools and expensive materials. All you need is to have at least a basic understanding of the operation of an inverter-type welding machine.

First step. Cut stainless steel wire or wire rod into pieces about 5 cm long. The required diameter of the wire used is 7-8 mm.

Second step. Prepare a plastic pipe to assemble the body of the device. A product with a diameter of about 50 mm will suffice.

Third step. Close the bottom of the main pipe with a fine mesh metal mesh. Select a mesh with such cells so that pieces of loaded stainless steel or wire rod cannot pass through them.

Fourth step. Completely fill the body with wire or rod, and then close the free opening of the tube with a second metal mesh.

Fifth step. Carefully and as tightly as possible, wind about 90 turns of copper wire around the middle part of the case.

Sixth step. Connect special adapters to the heater body for tapping into the heating or plumbing system. The scheme is extremely simple: water enters the heater through one adapter - heats up almost instantly - exits the heating system through the second adapter - batteries and pipes give off heat to the serviced room.

As a result of such simple manipulations, you will get an inexpensive and extremely easy-to-assemble device for efficient heating. The advantage of using a homemade induction boiler is that there is no need to allocate a separate boiler room for its installation. You simply cut out a part of the pipe near the entrance to the radiator and fix your homemade heater in its place.

Important: do not turn on the heater if there is no coolant in the heating system. In such a situation, the plastic body of the heater will simply melt and all your work will go down the drain.

Be sure to securely ground your homemade heater.

The device of the vortex induction heating unit

The assembly of such a unit will require you to have certain skills in handling a welding machine, as well as a three-phase transformer. The advantage of the vortex heater is the absence in its composition of elements that are not capable of enduring intense loads for a long time. That is, the risk of an early failure of the boiler is reduced by an order of magnitude.

Also among the advantages of the considered unit should be attributed the absence of detachable connections. This allows you to completely forget about the risk of leaks.

A homemade vortex induction boiler operates in an almost silent mode. This allows you to mount it anywhere you want. There are no harmful emissions either, so you don’t have to worry about the need to equip a reliable boiler room and install a chimney.

First step. Weld a pair of metal pipes with a diameter of about 2.5 cm to each other so that the result is a round product. The resulting workpiece is both the heating element of the boiler and its core.

Second step. Install the resulting circle in a plastic pipe of a suitable size.

Third step. Wind on a plastic case from materials you already know. Thanks to such a winding, the efficiency and productivity of the unit will be significantly increased.

Fourth step. Place the plastic housing in a good quality insulating bag. It will prevent possible leakage of electric current and will contribute to a significant reduction in heat loss.

Heating will be carried out due to the contact of the coolant with the same winding. Winding and all further actions are performed in the same way as in the case of an ordinary induction installation, discussed in the previous instructions.

Important notes on installation and use of the boiler

Homemade induction boilers are extremely easy to assemble, install and operate. However, before you start using this kind of heater, you need to know a few important rules, namely:

It is strongly recommended to equip the boiler nozzle with a blast valve. Through this simple device, you can, if necessary, rid the system of excess air, normalizing the pressure and ensuring optimal operating conditions.

Thus, from inexpensive materials with the help of simple tools, you can assemble a complete installation for efficient space heating and water heating. Follow the instructions, remember the special recommendations, and very soon you will be able to enjoy the warmth in your own home.

Successful work!

Video - DIY induction boiler

So I give everyone an example of both China and the West ..

While I had a welder weighing more than 40 kg, the counter did not hold well and the plugs flew out, I could not transport it without a car, and my navel tore for transfer, I dreamed of small devices and welding aluminum with an ordinary welder. And all smart electronic engineers did not shake their brains, and referred to smart formulas.

But then the West poured in, followed by China .. And the Miracles began!!! And now the LED lamp gives approximately the same luminous flux, but takes 10 times less electricity, Welding machines are almost 20 times lighter!!! I now have such an inverter 2.5 kg, it works with electrodes from 1 mm2 to 4 mm2 in cross section, and it consumes three times less electricity. And I don't care about the laws of J. Lenz, or whatever they are. I got more economical, practical, profitable products and tools. And that means it works, in spite of our smart people and smart girls from the 17th century !!! I personally need practical things that save my budget. And, by the way, in terms of heating and the power of these heaters .. they came up with MONOPOLIES from the Government those formulas that did not exist under the system of supply and distribution and the State Construction Committee of the USSR. Then the power of paid thermal energy was calculated and paid for by the output power of each section of the heating battery, which was also measured in Gcal. I worked in the supply chain and dealt with a range of over 10,000 items. And therefore, I’m just fooling from the fact that now they don’t consider it from the hot water flowing per unit time, and the difference in temperature loss at the inlet at the outlet, but they count it by kW per 1 m2 instead of 1 kW of one section of a cast-iron or aluminum battery, and refer to convection heat walls, ceilings, and other load-bearing structures. It seems that these carriers also emit heat, which also needs to be taken into account when consuming the coolant. But not by the sensor on the section, and not by the volume of the passed coolant per unit of time. Namely, these units should consider the cost of money for the production and return of this heat. But who will check it at the Government level?? He needs to collect more money from the population through the monopolies of Lukoil and other resource companies. That is why these few calculation norms have been introduced for calculating payment from the population, which includes smart debaters. And therefore, smart people who believe who are on 1 m2, then on the induction of the walls .. please, it’s better to be silent.

This fee is for the Owner's heating costs when choosing a heater. It needs to be covered, and not to show knowledge of the THEORY of the 17-19 centuries ...

Look outside, and look at the Calendar. Now is the 2nd decade of the 21st century. And the satellites from Venus are returning .. And you are sitting there, on the heating elements ... Well, you are sitting. I choose Induction heating and water heater. My pension says so.

When choosing a boiler for heating a house, the owners are guided, first of all, by what heating source is available for the room. Gas is the cheapest fuel, but far from being supplied to settlements. Electricity is the most common, but not the cheapest. An induction heating boiler produces a fairly high efficiency, with less electricity consumption, compared to other electric options.

The basis of the principle of operation of the boiler is the creation of heat from electrical energy. The action of electromagnetic induction is as follows - we pass a current through a coil wound with wire, an electromagnetic field arises around this winding. The metal core placed in the coil (having the property of being attracted by a magnet) will begin to heat up quickly.

Heat Generator Mechanism: It is an electrical inductor, consisting of a primary, a secondary winding and a core. Processing electricity into eddy currents, the primary winding directs the electric field to the secondary winding, which in turn transfers energy to the carrier. Under the influence of an electromagnetic field, eddy currents are formed in the body and core. They heat up the metal. Water takes heat from the core and distributes it throughout the building.

The operation of the induction cooker is based on the same principle. Such tiles are much more economical than conventional electric stoves. This is achieved by avoiding heat loss when transferring heat from the heater to the cookware. Marketers today designate induction heating boilers as advanced developments created on a new principle. But in reality, this is not entirely true. Inductive principles have been applied since the last century for melting furnaces. Also, no new materials are used for the manufacture of boilers.

M. Faraday discovered the phenomenon of induction in 1831.

Induction options are safer, compared to other heating boilers, they practically do not need maintenance. They do not contain dynamic parts, and as a result, they do not have mechanical wear. With sufficient cooling, the life of the coil is not limited. Such boilers do not require a separate room. Compared with, they practically do not need preventive work.

Advantages of an induction boiler:

- Constant circulation of the coolant;

- No heating elements;

- Noiselessness.

An inductive electric boiler is able to heat not only the area of a small private house, but also industrial premises, while not requiring large installation and maintenance costs. The induction heating boilers on the market are not cheap. The reason is in the sensors of the system. The inverter used in the control system increases the cost of the heating boiler.

How to make an induction heating boiler with your own hands

Opponents of the installation of induction boilers cite the law of conservation - 1 kW of electricity is able to generate thermal energy also no more than 1 kW. Yes, any water heater, consuming 1 kW of electricity, also produces 1 kW of energy. But not all of it is thermal. Induction water heaters are more productive in the production of thermal energy, in comparison with heating elements. Making a homemade inductive water heater is not difficult. The materials used in this case can be found without much difficulty and at a low price. The circuit of such an inductive device is quite simple.

To convert electricity into heat, you need:

- Inductor;

- AC 50 Hz;

- The core of the material to which the magnet "sticks";

- Drawings of an induction heating boiler (not a problem to find).

For the body of the induction boiler, you need to take a pipe with a diameter of 5 cm. The pipe is filled with pieces of wire, 5-7 cm, with a diameter of not more than 7 mm. To connect the boiler to the pipe system, you will need adapters. The scheme of the heating system will help determine the characteristics.

It is better to install an automatic shutdown of electricity in the event of a coolant leakage. In this case, the electromagnetic field will not disappear if the power supply is not turned off, and the case with fasteners will simply melt.

We make an induction coil - the main heating element. To do this, we take a copper wire, wrap it around the body, approximately 85-99 turns. We keep the interval between turns equal. The simplest induction boiler is ready. Such an inductor can be installed anywhere in the pipeline. The induction steam generator works on the same principle.

Learn about the advantages and disadvantages of a double-circuit boiler in the following material:

Modernization of induction heating

Induction heating systems often have favorable reviews. Silence, efficiency and longevity are the indisputable pluses of the heating system. One of the varieties of the system is the operation of an induction water heater for heating. An induction water heater can be bought and installed in a piping system.

You can choose a scheme for induction heating with your own hands. In this case, you can save your money well.

But, for more efficient operation of the induction system, it is important to know some of the nuances. Installing the induction cooker in the structure, it is connected to the charger, batteries and inverter. An inverter is a device that converts direct current into alternating current. Its use reduces the amount of electricity consumed for the heating system to virtually zero.

For less energy consumption, you need:

- 4 kW inverter;

- 2 batteries 250 Ah;

- Battery charger.

We connect 2 batteries synchronously, and charge to them. They generate direct current and feed it to the inverter. The inverter converts direct current into alternating current. Then the inverter transfers the current to the induction cooker, and the charger continuously charges the batteries. Thus, the consumption of the charger at 24 V is the energy consumption of induction heating at home. The cost of the pump is calculated separately. Induction heaters are used only in versions with forced circulation.

Description of inverter heating boiler

The inverter boiler has become available to the domestic consumer, unlike industrial enterprises, relatively recently. At the heart of the boiler device are 2 main cylinders placed in the outer one. The option of such a boiler is safer. With proper installation, fire safety is orders of magnitude higher compared to gas, coal and wood boilers.

The principle of operation of the inverter boiler:

- The coolant flows in the inner cylinder;

- A cylinder that passes current through itself provides heating of the coolant;

- The outer cylinder acts as a heat insulator;

- The boiler is based on electromagnetic induction.

The mechanism of the inverter boiler virtually eliminates coolant leakage. An important quality is that any option (water, antifreeze, oil) can be used as a coolant. The advantage of using antifreeze is that when the boiler is turned off in winter, the battery will not freeze or burst. Low power inverter boiler models often have the ability to run on battery power, which significantly reduces energy costs.

When installing an inverter boiler in a heating system, it is important to properly connect the ground.

The inverter system will allow you to quickly dial the desired temperature, and provide an economical consumption of electricity. Such systems are successfully used in the production of split systems. The inverter air conditioner has a much longer service life than standard split systems.

Do-it-yourself induction heating boiler (video)

Induction devices are practical and economical systems that do not require difficult installation and maintenance. As a rule, small dimensions allow installation in any premises, and do not require restructuring of the heating system. The fire safety of induction heating boilers allows them to be used in country houses, even if the owners do not appear there often.

Read also...

- Education of the USSR: prerequisites, stages, significance When the USSR was created

- Education of the USSR: briefly about everything What led to the formation of the USSR

- Socialist-Revolutionary Party: who are they? Their goals and program. Political parties at the beginning of the 20th century Socialist-Revolutionaries party program table briefly

- Vitaprost rectal suppositories: how to use the drug correctly You can take Vitaprost without a doctor's prescription