Features of well masonry brick walls. Insulation of a stone house: well masonry Features of well brick masonry

Well masonry involves the creation of a three-layer structure, in which the gap between the outer and inner brick rows remains empty during the construction phase. After he.

If we talk about what types of insulation are available for such thermal insulation, then almost any options are possible. As a rule, they are cement mortar mixed with straw or sawdust, slag and mineral wool. An excellent and very common solution is to choose a foam base for insulation.

The profitability of this material is explained by the fact that polystyrene foam has a low cost, but its insulating properties are very good. In the cold season it perfectly retains heat inside the building, and in the warm season it keeps it cool.

Advantages of well masonry

This type of insulation, such as well masonry with insulation, has many significant advantages. Let's analyze in detail its positive qualities:

- this method allows you to reduce the amount of brick for work by about 18 percent (compared to solid masonry);

- it is not necessary to use “warm” styling solutions;

- the resulting overlap is light in weight and has medium thickness, that is wall materials save money, and the load on the foundation is softened;

- If installation rules are strictly followed, there is no threat of condensation on the inside walls;

- The thermal insulation turns out to be resistant to fires, that is, fireproof;

- The facade of the house gains aesthetics without any additional costs.

Polystyrene foam as insulation: characteristic features

To really choose reliable material- heat insulator, it is important to find out in advance unique properties. What kind of insulation does it have? specifications?

- Ability to form complex configurations. The structure of the foam is such that with certain processing it easily changes its shape, adapting to specific needs;

- At low density, foam is characterized by high resistance to compression. Thus, he can withstand a fair amount of pressure.

- Has a low level of thermal conductivity.

- The fire resistance of the material is manifested in the fact that under the influence of fire it gradually melts and does not burst into flames, spreading with catastrophic speed. However, it is important to know: combustion leads to the appearance of a poisonous odor, so face protection is necessary.

- Excellent sound insulation ability protects against noise from the street.

- Low moisture absorption prevents the insulation from changing its shape.

- Foam plastic - environmentally friendly pure material. It is absolutely non-toxic and does not crumble into dust under the influence of time.

- Well masonry with insulation is easy to install. This allows you to carry out insulation work yourself, without the involvement of qualified specialists.

- The low cost of polystyrene foam is also a pleasant surprise.

Additional mounting accessories

Thermal insulation of a house with a well type of masonry will require the use, in addition to the foam itself, of the following auxiliary means:

- glue;

- primer;

- putty;

- polyurethane foam;

- reinforced mesh;

- base profile;

- putty knife;

- hammer;

- dowels;

- hammer drill

Insulation installation process

Now, having decided what technical characteristics polystyrene foam has as insulation, as well as having secured the necessary materials at hand, you can finally begin work. The algorithm should be like this:

- We prepare the walls: clean them from dust and dirt, remove interfering elements. Cracks and crevices must be primed and treated with putty. It is advisable to cover the surface waterproofing film(you can attach it with a furniture stapler).

- We mark the bottom line of the insulated wall and apply markings using a level. We fasten the base profile so that the foam does not slide down during fastening.

- We dilute the glue according to the instructions. Apply it with a spatula thin layer along the perimeter of the foam and a little in the center. After about 20 minutes, press it firmly against the wall and level it. Each subsequent piece of foam must be checked with a level.

- For greater reliability, it is also possible to secure the insulation with nails - umbrellas.

- We apply a reinforcing mesh onto the glue on top of the foam. After drying, add plaster.

Well, you have found out what kind of insulation is available in the case of well-type masonry, and what is the advantage of using a material such as polystyrene foam. If all requirements are carefully followed, the result will please you high quality keeping the house warm.

EFFICIENT WELL BRICK MASONRY

Effective well masonry 530mm

Effective well masonry 640mm

Recently, the requirements for the thermal efficiency of buildings have increased significantly. In this regard, almost any solid masonry does not provide the required thermal insulation parameters. One solution to this problem is effective well brickwork.

The well masonry consists of two parallel brick walls, leaving empty space between them. The walls are connected to each other by transverse brick diaphragms located at intervals of 650 - 1200 mm. This creates wells that are filled with insulation.

The most suitable insulation can be used different materials- lightweight concrete, backfill, slab materials. Exist various options effective well masonry, designed for one or another type of insulation. Despite significantly better thermal insulation performance compared to solid masonry, well masonry still has a drawback in the form of those very transverse walls that form cold bridges.

Well masonry should not be confused with lining load-bearing walls with brick. The difference between them is that in effective well masonry the outer and inner walls are rigidly connected and form a single supporting structure. In turn, brick cladding involves the connection of the outer brick with load-bearing wall, only with the help of thin flexible connections. At the same time, the external brick cladding holds on to the load-bearing wall and does not take any loads other than its own weight.

This difference contains another significant drawback of well masonry.

Over time, some types of slab insulation inside the wall may lose their thermal insulation ability and will have to be replaced. If external cladding brick, even if high costs, but still allows this to be done, then dismantling and restoring the outer wall of the well masonry is a much more complex and time-consuming procedure.

u13751.netangels.ru

Well brickwork

In terms of financial costs, the construction of external brick walls by creating a well brickwork can be considered the most economical.

What is the well bricklaying method?

With this method of creating a structure, the outer wall is actually laid out from two independent fences, which are connected to each other by brick

- vertical,

- horizontal.

In this case, so-called closed wells are formed. As the masonry is being created, they are filled with insulation. This method of constructing walls while simultaneously insulating them makes it possible to perfectly protect the insulation itself from external influences and extend its service life. The disadvantage of this method is some weakening of the structural strength of the wall.

Requirements for insulation using the well bricklaying method

Taking into account the fact that in the future it is not possible to carry out repair and restoration work on such well brickwork, special requirements are imposed on the insulation used. The most important and basic among them are:

- high resistance of the material to mechanical deformation,

- high degree of moisture resistance.

The most common insulation materials that meet the above requirements are:

- mineral wool,

- glass fiber wool,

- products made of polystyrene foam, polyurethane foam and other foamed polymers.

Cold bridges: connections between external and internal masonry

It should be noted that the internal and external walls during the production of well brickwork have rigid or flexible mutual connections. These connections belong to the category of so-called “cold bridges” if we consider them from the perspective of thermal engineering. In some cases, they significantly reduce the thermal resistance of the enclosing structure and lead to dismal results in terms of energy efficiency.

The maximum reduction in heat transfer resistance is obtained when creating rigid brick connections. From the point of view of eliminating the negative phenomena caused by the appearance of “cold bridges,” the use of special fiberglass connections can be considered a promising option. They will significantly reduce heat loss. IN in this case we can talk about exceeding them by only 2-3%.

Moisture condensation inside well brickwork

When designing walls created using well brickwork, and their further operation under the established conditions internal insulation, there is another very serious problem. We are talking about the appearance of condensation inside the erected structure. There is a dew point in the insulation, which leads to dampening of the material and a gradual decrease in its heat-insulating properties.

Regardless of the time of year, the insulation does not dry out, since even in summer the outer layer turns into a kind of vapor barrier that prevents moisture evaporation. This deficiency must and can be combated quite effectively. To eliminate condensation it is used newest method— vapor barrier layer with arrangement of an air ventilation gap.

The technology for creating such a layer is as follows:

- the internal load-bearing wall of the future building is pre-built, which is made from standard building bricks or blocks;

- are placed on the anchors thermal insulation boards, which are pre-laid into the masonry of the load-bearing wall itself;

- the slabs are fastened to the masonry using spring washers with a special anti-corrosion coating;

- is being built outer wall with sealing of anchors in the joints of the masonry, which is protected by the selected insulation from adverse external influences and is at the same time the facade of the building;

- the ventilation air gap allows moisture to evaporate and the insulation to dry, increasing the quality of thermal insulation.

You should not think that these days all issues related to well brickwork have been resolved. Walls erected using this method have many advantages, but they are also not without drawbacks that still cannot be eliminated. First of all, this is the high cost and high labor intensity of equipping such walls, as well as the lack of an alternative to insulation.

remonthome.com

Do-it-yourself well brickwork - device, pros and cons

The cost of energy supply is rising, which means modern house must meet the most stringent heat loss requirements. So using a homogeneous material without insulation for walls is an unacceptable luxury today. For example, to ensure the required thermal conductivity, for example, for St. Petersburg, a brick wall must be more than two meters thick! Specific numbers the permissible thermal conductivity is given in SNiP II-3-79, Addendum No. 3 “Building Heat Engineering”.

That is why all kinds of layered wall masonry are becoming so widespread today. Today we will talk about well brickwork, when insulation is laid inside the wall. The thickness of such a wall, which meets all heat loss standards, is 64 cm! At the same time, we save material and reduce the load on the foundation.

Layout of well brickwork

- facing brick.

- Insulation (expanded polystyrene grade PSB-S 25, extruded polystyrene foam Type 35, URSA P30 mineral wool board, TechnoBlock mineral wool board)

- primer layer deep penetration GLIMS-Ground and mounting layer adhesive composition GLIMS-KF.

- solid brick brand M100

- reinforcing frame made of wire with a diameter of 4 mm, class BP1.

- plaster layer GLIMS-GS

- layer finishing putty GLIMS-GYPSUM.

Vertical diaphragms are installed no further than 1170mm apart; reinforcement of vertical diaphragms should be done every 6 rows of masonry. Horizontal diaphragms are installed at the level of support of the floor slabs and under window openings, by overlap of interlocking bricks from the inner and outer layers of masonry. Under the latter, in the seams of the masonry walls and along the underlying layer of cement mortar, reinforcement ties are laid in the form welded mesh made of wire of class VR-1, with a diameter of no more than 4 mm, which simultaneously serves as a brick support during the installation of diaphragms.

Scheme of brick well masonry, with a load-bearing wall thickness of 25 cm:

Installation of a horizontal diaphragm in a well masonry, with a load-bearing wall thickness of 25 cm.

- floor slab (PPS, PC, PNO).

- a layer of finishing putty GIPS-GLIMS.

- layer plaster mixture GIPS-GS.

- solid brick.

- jumpers.

- steel corner.

- face brick.

- reinforcing mesh made of VR-1 wire, 4 mm in diameter.

- layer of thermal insulation.

- primer layer and installation adhesive composition.

- sound insulation layer, 30-50mm thick.

- layer technical insulation, (glassine P-300).

- self-leveling layer of self-leveling floor GLIMS-SL, 20-30mm thick.

- waterproofing film (Yutafol D110 Standard)

- backing layer.

- facial flooring(laminate, linoleum, carpet, porcelain tiles)

Section: Encyclopedia of building materials

Tags: brick, masonry, walls, insulation

sumeu.ru

Brickwork with insulation » well masonry

IN Lately Not only the brick itself is being actively improved, but also the methods of laying it. Both full-bodied and hollow varieties, both single, double and one-and-a-half are used. The presence of pores and voids in brick has a positive effect on sound and heat insulation, and also helps reduce the weight of the structure.

Lightening the structure, however, can be achieved using lightweight masonry. This technique involves reducing the load on the structure frame, saving building materials, as well as increasing the sound insulation and heat insulation performance of the home. There are a couple of varieties. The first option involves a construction of a pair of brick walls, and a material is laid between them, which increases thermal insulation characteristics. The second option involves installing only one brick wall, which is insulated with heat-insulating boards.

Well masonry is brickwork with insulation, the role of which is played by air. The outer wall is only half a brick thick. After it there is a cavity filled with air, followed by interior wall, the thickness of which ranges from one to one and a half bricks. Between the outer and inner walls, every 4-5 rows, dressings are organized with a butt row. When tying the brick, it is quite possible to replace it with steel reinforcing bars, the distance between which will be 50 centimeters. To ensure reliable adhesion to the mortar, the ends of these rods should not reach the edges of the walls by approximately 4-6 centimeters.

Warm brickwork may well have a slightly different design. In general, this is the same well masonry, but the voids are filled with concrete or slag. In such a situation, both the outer and inner walls can be half a brick thick. The empty space is covered with two-row continuous masonry, the distance between which is 4 rows. The role of horizontal rows is to give the wall additional strength. Slags for backfilling must lie on the floor for at least six months. outdoors. This method of masonry is perfect for houses with 1-2 floors.

Slag can be easily replaced with a light type of concrete. This option involves making lintels using interlocking bricks in one row, following a step of 1-3 rows. If the wall is 51-65 centimeters thick, then the bundles can be placed in one row. If the wall thickness is 38 centimeters, the ligaments should be staggered. The voids formed between rows of bricks can even be filled plain concrete, to which broken brick is added. Such a wall can be built even in multi-storey building. Walls that are filled lightweight concrete, have an increased degree of resistance to seismic influences.

More articles on this topic

| Waterproofing brickwork Stonework tends to absorb water, so when it comes into contact with the soil it can become saturated with water. Water may well reach even the height of the second floor along the masonry, causing dampness in the premises. Waterproofing is used to protect the foundation and walls. |

|

| Flexible ties for brickwork Brick construction has always managed to preserve high level popularity, as brick has excellent technical characteristics. However, all the advantages of this construction technique can be negated if the use of flexible connections is neglected. |

|

| Decorative brickwork If you want your home to look original and different from others, then you definitely need to use facing bricks. Read this article on how to install it correctly. |

postroim-dom-sami.ru

Insulation of well masonry

Today, there are many residential buildings with boundary wall structures built according to the “well masonry” type, which require additional insulation. This construct consists of:

Today, there are many residential buildings with boundary wall structures built according to the “well masonry” type, which require additional insulation. This construct consists of:

1) Load-bearing wall (foam concrete, brick), 2) Insulation layer (usually mineral wool), 3) Fasteners, 4) Facing brick, 5) Waterproofing.

So that's the problem, as time goes on mineral wool insulation became unusable (partially crumbled, got wet, etc.), and at the same time ceased to perform its functions, bringing with it a number of problems related to insulation. And how to solve this problem if we are talking about apartment buildings or even private houses and cottages. Should we insulate each apartment from the inside or the entire house from the outside? Let’s assume that outside, it’s again to hang sheets of insulation on the facing brick (not forgetting about technology and using quality materials, which is often not taken into account), then facade material(porcelain tiles, siding, corrugated sheets, etc.). Or all the same from the inside, sacrificing good repairs while losing usable area? Agree, the two options do not fit into the framework of reason, incurring large financial costs and many factors.

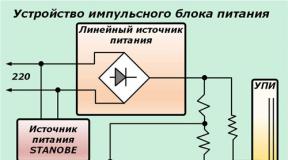

If this question had been asked “yesterday,” we would have had to choose one of two options. But today there is a fairly promising solution to these problems in insulation that solves a number of problems and saves financial costs - this is the use of sprayed thermal insulation based on Ecotermix polyurethane foam. The material is superior to many traditional materials by many indicators. In this case, we will consider cast-in-place thermal insulation material " Ecotermix 555«

Let's take a closer look this technology using an example of a completed object for a clearer explanation. In the house, the thermometer does not exceed +15, the walls freeze, the owner incurs high costs for heating materials for the boiler installation.

Our company's specialists inspected the house. Attention was drawn to the external walls, which consist of foam concrete blocks 250 mm wide and lined decorative bricks, there is an air gap of about 50 mm between the wall and the brick.

This structure of the well masonry of the house did not fulfill its tasks and the thermal insulation was no longer effective for a long time, as described above. It was decided to fill this space with Ecotermix 555 polyurethane foam to restore the heat-saving ability of the structure to the required standards.

The technology for performing the work consisted of drilling 5 holes in the cement mortar joints of the brickwork with a diameter of 10 mm. per 1 m2, without disturbing appearance Houses. After preparing the holes in air gap We downloaded Ecotermix 555, after all the insulation, the holes in the masonry were filled with mortar. The house did not change visually, but the Customer immediately felt the difference. The house became warmer and more comfortable, freezing of the walls was completely eliminated, and the cost of heating materials decreased by up to 50%.

This technology can be widely used in various structures for the purpose of insulation or filling air space in inaccessible places. For example, it is widely used in the “Khrushchev 434” series of house construction, for insulating the under-roof space between two concrete floors to prevent heat leakage through the roof, which results in ice and icicles on the roofs ( constant problem Housing and communal services). It is also used in frame housing construction. Watch the video.

Ecotermix 555 video Thermal insulation technology

More detailed advice can be obtained from our specialists in your region.

Or call the call center:

+7 923 775-13-44 / +7 923 775-13-22

www.termospray.ru

Insulation of a brick house, well masonry. Insulation of the walls of a brick house

Insulation of wooden floors

Read more…

Read more…

insulate brick house

Well masonry

types of insulation

Styrofoam

The properties of any of the insulation materials are such that it retains heat in winter and coolness in summer, since it increases the width of the walls.

New insulation materials expel moisture and steam from the house in a single direction, that is, they do not absorb or allow it to pass inside.

It is estimated that on average about 40% of energy is spent on cooling and heating a residential building, that is, there will be another reason to neglect the annual unnecessary expenditure of money.

The point of the insulation is to use the qualities of a 10 cm wide insulation to increase the thickness of your wall to 100 cm in stone equivalent. And thus reduce the cost of heating the street in winter, and cooling the apartment in summer, since it is warm or cold air will not evaporate through the walls as easily and quickly as it did before. As a result, by insulating a brick house, you will save your money.

Video

rmnt.net

Insulation of a brick house, well masonry. Insulation of walls of a brick house | MRabochiy.ru

Insulation of wooden floors

Floors country houses usually wooden and logs are used as floors.

Floors country houses usually wooden and logs are used as floors.

From spring to autumn, the most noticeable thing is a cold, uninsulated floor made of boards or chipboard.

Read more…

Insulating a balcony using suspended ceilings

If the balcony was not properly insulated before the onset of the cold season, then heat loss during severe frosts will be simply colossal.

If the balcony was not properly insulated before the onset of the cold season, then heat loss during severe frosts will be simply colossal.

Especially it concerns glazed loggias, where the owners moved the entire kitchen.

Read more…

Brick keeps heat in the house very poorly. There is a very popular method that will help insulate a brick house. This is well masonry, when free spaces are specially kept between versts in order to lay insulation later. This role can be played by slag, expanded clay, cement mortar into which reeds or chopped straw, sawdust or other various materials are crushed.

At the same time, the inner and outer versts are tied through a couple of rows with layers of bricks and masonry mesh. So, you can build a house using one of the different types of hand-made well masonry, which has excellent technology: first the front and inner versts are laid out, then a gap of 5 to 10 cm remains between them.

Bandaging is carried out through 5 rows, but this will depend on how many floors there are under the ceiling of the reinforcement belt; The rib sides of the walls are laid with straight brick masonry in the places where doors and windows are installed; the space that has formed between the versts of masonry is filled with slabs of polystyrene foam or expanded polystyrene.

Well masonry

This type of construction of brick walls gives a chance to insulate them by 200 percent, and at the same time there is no need to increase the amount of bricks in the installation.

There is another method for insulating a brick house: laying stone in such a way that small niches, the size of which range from 5 to 7 cm, remain inside.

Such gaps can be left empty, but it will be better if filled with insulation - expanded clay or slag.

Another excellent way to insulate walls is to increase the thickness of the joints formed when laying bricks.

Here you need to simultaneously use warmed solutions or warm plasters, after that you can plaster the wall.

For wall insulation brick house there are different types of insulation. The most common, in my opinion, are: polystyrene foam and mineral wool tiles. At the same time, insulation materials will in no way interfere with your plans to clad your house with ceramic tiles or wood, since it is possible to lay it between the wall and the cladding.

The advantage of mineral wool over white polystyrene foam is that it does not burn, and polystyrene foam is more affordable.

The advantage of mineral wool over white polystyrene foam is that it does not burn, and polystyrene foam is more affordable.

Styrofoam even cheaper and holds heat a little worse, but not so much that it can be discounted.

Well masonry - disadvantages and advantages of its use in the construction of modern residential buildings

Well masonry- This is a structure of three layers, in which the wall is laid out from a pair of separate walls having a thickness of no more than half a brick.

These walls are connected to each other by vertical and horizontal brick bridges, which form closed wells.

The inner layer is most often made of bricks or blocks, and the outer layer is made of ceramic stone, various types brick, silicate, as well as concrete and expanded clay concrete blocks.

Well masonry: Pros and Cons

Advantages of well masonry:

- Reduction in brick consumption by about 18% in relation to its continuous laying;

- Relatively small thickness and weight of the floor, which leads to both savings on wall materials and mitigation of demands on the bearing capacity of the foundation;

- Correct calculations eliminate the danger of moisture condensation inside parts of the wall;

- It is not important to use “warm” masonry mortars;

- Economical ceramic and clinker bricks American format;

- Fire resistance;

- Aesthetic, does not require separate work and costs, finished facade building.

Disadvantages of well masonry:

- Helps reduce the strength of the building and disrupts uniformity.

- Promotes the formation of condensation on the walls of the home, especially in winter.

- It is extremely unstable to temperature changes and can lead to rapid destruction of insulation.

As you can see, there are no clear arguments in favor of choosing or not using this material, so you will have to make your own decision, but you already know what to expect from covering with well masonry.

Well masonry - disadvantages that cannot be ignored

Of course, well masonry has a number of advantages, the main one of which is cost-effectiveness.

But when constructing a large-scale project for a serious customer, before deciding to insulate a building with this particular masonry, you must take into account all the possible risks of using it.

Therefore, we will list the main disadvantages of well masonry so that you understand what you may encounter during construction:

Lightweight well masonry

Lightweight well masonry is made of a pair of walls half a brick wide, between which insulating raw materials are located.

At intervals of 2-5 rows of masonry, the walls are connected with bonded rows. The thickness of the internal load-bearing walls reaches 25 cm. Partitions are placed in half a brick or a quarter. If the partition has a length of more than 1.5 m, then it is necessary to reinforce the masonry, for example with steel wire.

The voids formed between the masonry are filled with concrete, thus creating robust construction, which does not contain insulation.

This perfect option For non-residential premises, which do not require thermal insulation. The filling between the blocks is standard and is carried out in stages as the solution is filled and hardened.

Using universal waterproofing, you can achieve the desired heat concentration inside the structure. This will allow maximum insulation of the walls without increasing the mass of the slab. Lightweight masonry can be used in high-rise buildings, it is safe and quite easy to implement.

Well masonry with insulation

The issue of using insulation materials for well masonry deserves special attention.

The very idea of using an insulating layer in the middle wall structure originated in the mid-twentieth century - various sawdust, moss and peat were used at that time as a means of insulation between brick walls.

Currently, it allows the use of almost any type of thermal insulation materials, however, when choosing it, it is necessary to take into account the impossibility of repair and restoration work.

Therefore, the main requirements for insulating materials are resistance to deformation and humidity. These requirements are fully met, and, as a rule, materials such as glass wool, mineral wool and polystyrene foam are often used.

It is also possible to use expanded clay and sawdust.

Should well masonry be used in construction?

We have voiced all the main characteristics of the use of well masonry in the construction of various buildings, and after studying the disadvantages and advantages, a conclusion is brewing - this material, of course, is easy to use and affordable in price, but the risks are too great and often unforeseen expenses, after discovering inaccuracies in the work, cover the expected benefits.

You can also watch the video: well masonry

How to build a warm house and at the same time save on building materials? For this purpose, there is a well masonry of brick walls. Energy efficiency is one of the the most important qualities modern buildings. It is very difficult to achieve it by simply thickening the walls. To do this, even in moderate latitudes, the brickwork of the walls must be at least 2 m wide.

It is not difficult to imagine how expensive this option is. Therefore, a compromise brickwork technology was developed, which ensures the presence of an additional thermal insulation layer in the brick wall system.

This technology assumes that the brickwork of external walls is made in a “lightweight” version with the formation of internal “wells” filled with insulation. Thanks to this method, the thermal insulation characteristics walls, brick pediment, internal partitions. A variety of materials are used as insulation materials - loose materials (sawdust, slag), slab materials (foam plastic, mineral wool), “light” types of concrete (polystyrene concrete, expanded clay concrete and others). To ensure the required level of strength, parallel walls are fastened together by horizontal and vertical jumpers in brick walls.

The cost-effectiveness of this method determines its popularity. But, following well technology, it is necessary to take into account some nuances. For example, when performing this kind of brickwork in winter conditions, in conditions high humidity You may encounter a decrease in the level of thermal insulation of the wall. Therefore, it is necessary to provide a ventilation gap of at least 10 mm thick between the thermal insulation layer and the brickwork.

Advantages and disadvantages

The construction of brick walls using the well method has its advantages, including the following:

- reduction in thermal conductivity when constructing thinner brick walls;

- no need for additional wall insulation;

- less load on the building foundation while reducing the total mass of the partitions;

- more economical use of materials, cheaper construction costs;

- reduction of construction time.

However, this technology also has its disadvantages, including:

- reduction in the degree of structural strength due to the heterogeneity of the wall;

- risk of occurrence in winter period condensation inside the insulating material due to the temperature difference between the outside and inside the room.

To eliminate these risks, it will be necessary to calculate and install horizontal and vertical diaphragms, as well as cover internal surfaces“wells” with vapor barrier material.

Types of well-type masonry

Existing well types of brickwork differ in the following indicators:

- total wall thickness;

- thickness of external partitions;

- dimensions of “wells” (distance between walls);

- type of insulation material;

- material and method of installation of diaphragms.

IN construction practice The following standards are known:

- total wall thickness - 33-62 cm (depending on the design, dimensions of the “well” and the thickness of both walls);

- wall thickness options - a quarter of a brick, half a brick (only for spoon rows), 1 full brick (when combining bonded rows with spoon rows);

- options for the width of the “wells” - half a brick, three quarters of a brick, 1 whole brick, one and a half bricks.

It should be noted here that most often both the outer and inner walls are laid out in half a brick. Sometimes exceptions to this rule are allowed: for example, the outer wall is built with half a brick, and the inner wall with a whole brick.

Execution technology

Specified installation technology more complex than standard brickwork. However, it is not so difficult that anyone can’t master it. The main thing that needs to be ensured is an accurate calculation of the volume of bricks and the selection of lintels.

- Well installation begins with the arrangement of the base of the wall. It, in particular, includes 2 solid brick rows. The stones are laid with bandaging for horizontal waterproofing foundation.

- After installing the base, they begin to lay out two parallel walls, as well as vertical diaphragms (partitions that connect the parallel walls). In some cases, instead of diaphragms, special pins are installed from metal fittings(diameter 6-8 mm). In this case, the corners can be laid out various configurations- parallel walls of equal thickness, with a thickened outer wall, with continuous installation.

- After laying 5-6 brick rows, the “wells” created in this way are filled insulation material. If slab insulation is used (mineral wool, expanded polystyrene), it is fixed with mounting adhesive (foam), if used bulk material, it must be compacted well.

- Next comes the turn of horizontal brick diaphragms. Diaphragms are 1-3 horizontal rows of bricks thick. With a diaphragm one brick thick, a greater degree of thermal insulation is provided; with a thickness of three bricks, the thermal insulation is less, but the degree of strength is higher. To provide reinforcement to the brickwork, sometimes reinforcement is placed at the bottom of the horizontal diaphragms. metal mesh. In some cases, vertically located brick diaphragms do not completely cover the “well” space, but only half. In this case, the reinforcement of brick walls suffers somewhat, but the thermal insulation coefficient increases.

It is worth paying attention to the fact that the brickwork near the openings is continuous. Under the windows, horizontal diaphragms are made at least two bricks thick.

Instead of a conclusion

The technology of brickwork in the form of a well requires the contractor to accurately count building materials and scrupulously follow the installation rules. If all the requirements for such masonry are met, the walls of the building will not only be warm, but will also be much cheaper.

Today, all over the world, such a branch of the national economy as construction is developing at a rapid pace. Hundreds of new buildings and structures are built every year. The most loved and widespread building materials are the following: concrete, reinforced concrete, plastic, metal tiles, metal-plastic, brick. Brick is undoubtedly the most practical of them. Currently, bricklaying is constantly being modernized, and more and more new methods are appearing. Brick is used for these purposes. different types: full-bodied, hollow, single one-and-a-half, double. Brick is most often used for the construction of residential and public buildings, where the most important thing is maintaining an optimal indoor microclimate.

To insulate brickwork, you can use several options - slag, mineral wool, glass wool, concrete. Masonry is carried out in several ways - three-layer with and without an air gap, or well.

Today, insulation has become very popular. It arose in the middle of the last century. Then moss, sawdust, and peat were used as insulation. IN modern world they are no longer ineffective and have been replaced by more modern materials. Insulation can be used in almost any type of construction where timber, concrete panels, brick walls. The last option is the most relevant. Let's take a closer look at how brickwork is laid with insulation, masonry techniques, and the advantages of this method.

Types of insulation and requirements

Bricklaying is a rather serious and complex task.

Most often, insulation inside brick structures is carried out using mineral wool, expanded polystyrene, and glass wool.

Some craftsmen fill the space between the walls with concrete or fill it with slag. This option also has its advantages, the main one being that this method of masonry increases the strength and durability of the structure. Any insulation must meet the following special requirements.

Firstly, it must be resistant to deformation. This property is especially important. So, under the influence of any natural factors, as well as under the force of gravity, it can change in size and shape.

Secondly, it is moisture resistance. Despite the fact that insulation is carried out inside the structure, moisture can get inside, which often leads to deformation and destruction of the material. And the latter, in turn, will affect thermal insulation properties enclosing structure. Insulation is carried out only with materials that do not allow moisture to pass through or absorb moisture. In addition, excess moisture can cause condensation. Fiberglass is most optimal for flexible connections between fences, as it has low thermal conductivity, high strength and does not allow moisture to pass through. There is one more universal insulation- this is air.

Well masonry

Wall insulation is often used for lightweight bricklaying. This reduces the main load on the building. In addition, this method allows you to save materials, increase the percentage of sound insulation and thermal insulation. Insulation in this case is of two types. In the first case, two brick walls are erected, and the voids between them are filled with an even layer of insulation. In the second case, only one wall is made, and then insulation is attached to it. Currently, well masonry is most often used. It is carried out as follows: first, an internal load-bearing wall is erected using ordinary bricks, after which an external wall half a brick thick is built.

The next step is to install dressings in several rows. For this you can use metal rods. Another type of masonry can be used, in which the voids are filled with slag or concrete. The walls are built half a brick thick. In this case, the slag must rest for some time (six months).

Three-layer masonry with and without gap

With this method, thermal insulation panels are laid in rows between load-bearing structures, they are fixed using anchors that are built into the wall. To prevent the formation of condensation in this case, you will need a vapor barrier. The front layer is laid out from ordinary facing bricks or stone. There is another way in which an air gap is created. This method is the most optimal, since it helps prevent the formation of condensation to a greater extent. The ventilation gap helps the insulation dry out. With this method, a load-bearing internal wall is first built from ordinary brick. Thermal insulation materials are mounted on anchors built into the wall.

In this option, flexible connections with clamps are used, which are needed to connect the insulation panels to the wall and create an air layer. Washers with stainless steel coating. The disadvantage of this method is that it is very labor-intensive.

Equipment and tools

Insulating brick will require tools. You can insulate it inside if you have insulation available (cotton wool, slag or concrete). In addition, you will need a vapor barrier layer. For the masonry itself, it is important to have a mortar based on sand and clay or cement, bricks, a mixing container, a building level, a trowel, a trowel, and shovels. You may need a ladder or grinder for. It is advisable to carry out insulation of bricks in dry and warm seasons to avoid the penetration of moisture that can accumulate between the walls. You can insulate the wall yourself or hire a team of specialists for this.

As mentioned above, moisture can accumulate inside the wall, so it is important to use only moisture-proof materials. The cheapest of them are glass wool or slag. The insulation should be laid flat.

Based on all of the above, we can conclude that when laying bricks, it is best to use insulation. It must meet the following requirements: be moisture resistant and resistant to deformation. It must be inside the structure, between load-bearing walls. You can insulate the walls various materials: mineral wool, slag, concrete, glass wool. There is another very good insulation- this is air. Laying should be done in several ways. The most common of them are well, three-layer with and without an air gap.

In any case, a bandage is made between the walls; it is done using metal pins that are attached to anchors. The space between the walls is filled with an even layer of material. To insulate a wall, you will need equipment and tools. You can purchase them at any specialized store. Therefore, thermal insulation is not a difficult task, but it requires certain knowledge and skills.