Wood-burning boiler for heating the house. Which wood-burning boilers are best suited for heating a private home? Cost of wood boilers for country houses.

We have to live in a time when the price of hydrocarbons, and especially gas, is rising. In this regard, the population is beginning to look for more practical and cheaper heat supply options. One of these options is heating with wood.

In our open spaces have become widespread heating boilers for a wood-burning house:

Additives are sometimes used like a wood stove in the basement or even on the first floor. When placed in a basement and not connected to any duct work, it will perform like a wood slab. The unit must have a minimum of 18 inches of clearance at the rear and sides on any combustible surface and have 48 inches of clearance at the front to load wood. The top of an overhead or wood stove must be at least 18 inches from a combustible wall or ceiling and must have a barometric damper chimney, if used, unless it has been approved by a recognized testing agency for smaller clearances.

- Pyrolysis heat-generating equipment. Widely represented by the brands Buderus, Opop, Atmos, Viessmann;

- Solid fuel boilers on wood long burning. Our market can boast of Lithuanian equipment from Stropuva and others;

- Classic heat generators, capable of functioning on any type solid fuel(Buderus, Dakon, etc.).

It is necessary to pay attention to the fact that to create a heat supply system with a heat source in the form of a wood-fired boiler, more significant capital investments will be required compared to creating a system with gas boilers. But in the future, the cost of producing one gigacalorie of heat will be less for the first system. Thus, investing once during construction more money, we will receive savings in further operation.

If set to wooden floor, under wooden slab or wooden superstructure, an appropriate thermal insulation must be installed. It won't be as effective as wooden superstructure connected to a stove with a blower because heated air will not be forced out of the wood stove.

Are they cheap and don't heat well?

A centrally heated wood kiln is a self-contained wood kiln that has its own ductwork and circulation fan, or an additional unit that uses the same duct system as an oil, gas, or electric kiln. The self-contained, self-ducted type is typically used in homes with electric or hot water baseboard systems that do not have ductwork. Advantage autonomous system is whole house air conditioning, electronic air purification or humidification is easily added.

Where are they used most often?

Wood-burning heating boilers are of greatest interest to the population who live in private houses. These boilers are most in demand among people who periodically live in their dachas.

Among them, there is high demand for medium and low-performance units. This is explained by the low square footage of the living quarters. We think you'll agree that in most cases a private house has less than a hundred square meters area.

This whole house, bake central heating, in which the air conditioner; an electronic air purifier or humidifier can be easily added. It is controlled by two side-by-side thermostats. The benefits of this type of stove are the homeowner's ability to burn wood as the primary fuel without the need to run a wood fire. A gas or oil burner ignites the wood. When the wood burns, the gas or oil burner takes over to keep the house comfortable.

Wood-burning boiler with top combustion of fuel

Sometimes called an outdoor oven. There are some advantages to this system. These systems heat water that is stored between the firebox and the outer casing. Typically these systems work in conjunction with gas, oil or electric oven. A water pump is used to transfer heated water to a water coil located at the top of the primary furnace. When the thermostat calls for heat, the pump transfers heated water to the coil. The furnace blower distributes heat into the rooms. The bad news is that these systems are called " open systems", which water is exposed to air.

Also, such equipment will be very convenient for summer residents, since it does not require special maintenance and is reliable in operation.

Pros and cons

When buying a wood-burning heating boiler, you need to keep a few points in mind:

- Most boilers were designed to burn lignite or hard coal. Consequently, the parameters that are indicated in the technical data sheet, for example, the power of the unit and the burning time of one bookmark, are written specifically for working on coal. For high-quality use of such a universal heat generator that will burn wood, you will need to perform calculations for your fuel and system; this fact must be taken into account;

- To maintain a constant temperature regime in a room heated by wood-burning heat generators, it is necessary to add fuel every couple of hours. You must understand that for the operation of such a boiler, your presence and the construction of a room for fuel will be required;

- Raw materials for firewood may vary from purchase to purchase, because of this, its calorific value will also differ;

- Wood-burning home heating boilers do not work well with automatic control systems for their operation. But if you still want to build an automated system, then you will need to have electric current, and this is already a dependence and a disadvantage. But a way out of this situation may be to build a heating system with natural circulation. If it is organized correctly, it will self-regulate.

This will often destroy the firebox. Many of them lasted only a few years. Due to the high cost of these systems, it removes any savings you would hope for by burning wood. Some manufacturers now use stainless steel, which is a deterrent but not guaranteed. These systems also use a huge amount of wood compared to an indoor oven or wood stove. The downside is that if you let the water cool without keeping enough wood in the firebox, it can take a long time to heat the water, leaving you with insufficient heat for a long time.

Disadvantages of wood boilers

- Such boilers are made of cast iron, so they have heavy weight;

- Waste from the wood processing industry is a low-calorie fuel and the most in demand. To achieve what you want high performance, it is necessary to burn a huge amount of such “waste”. As a result, by chasing cheap fuel you will receive comparable costs when operating a boiler of similar power on natural gas;

- Difficult task is maintaining a stable temperature regime during the operation of such devices. This is due to the lack of a high-quality regulatory mechanism for such equipment;

- Firewood has a low calorific value, therefore, boilers have low efficiency (does not exceed 70%). To obtain such efficiency, combustion chambers are made for the units large sizes, which increase the dimensions of the boiler (on our website there is a video and photo gallery that will confirm this).

Another disadvantage is that these systems are designed to burn wood at low fire rates. Even water at 180 degrees in a water storage system is very cold for wood. When the temperature of the firebox cools, it forms creosote, which is an insulator that limits the heat from the firebox to the water, making the boiler even more inefficient. In fact, State Farm's insurance company requires that a wood boiler be placed at least 75 feet from any building due to the creosote fire hazard.

Universal heating boilers: wood and electricity

Additionally, most of these systems produce so much smoke that many states and local communities have banned them. If a water pump is needed to pump the heated water, the boiler will not produce heat during a power outage or electric pump failure.

Wood boilers

Even with the shortcomings described above, boilers for heating a house using wood have their own segment in the consumer market, and there are no prerequisites for losing their position in the future. Conventional boilers have a lower price compared to pellet, pyrolysis and long-burning boilers.

Advice. If you want to create more quality system heating, then you need to look at pyrolysis boilers, although they are more expensive, they can pay for themselves in a shorter period of time.

They are not popular for several reasons. They are usually used in conjunction with a gas or oil boiler, which uses the same "closed" water supply system. This ensures that air cannot enter the water supply, which could cause corrosion and destruction of the primary boiler as well as the wood boiler. Water in a wood boiler that is only 180 degrees or colder is subject to the same creosote problem as an outdoor boiler. Also, if the wood fire is more than 212 degrees, which causes steam, it heats the water, safety valve blows steam out of your basement.

Pyrolysis boilers

This type of boiler is called both pyrolysis and gas generator. They have become widespread among country houses, in which they do not live throughout the heating season.

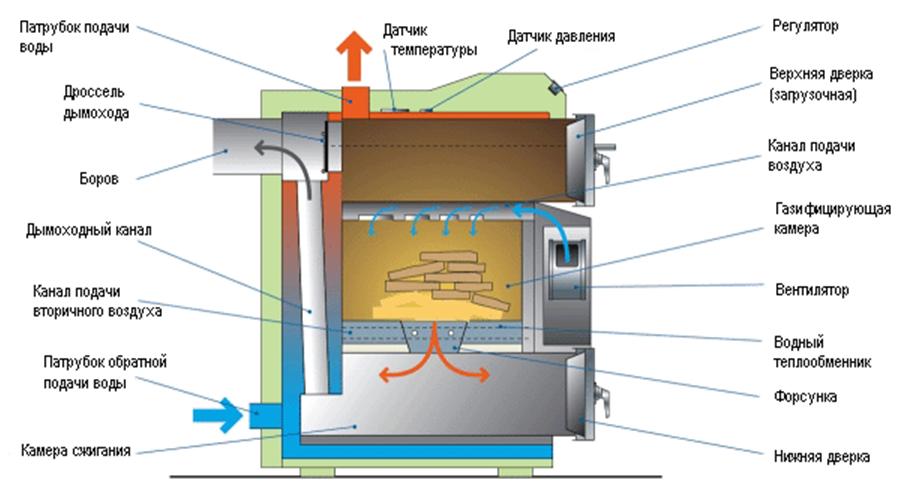

Let's look at the process of its work. Judging by the name, you can already guess that they generate gas, that is, they release it from fuel. The firewood in the firebox smolders slowly, air is added to it and a gas containing a high amount of CO is obtained.

This tends to be a common thorny issue with domestic wood fired boilers. A wood boiler that requires a water pump will not provide heat during a power failure or water pump failure. Or one will save on your gas or oil bill. However, this may not save on overall heating costs. Wood pellets are usually very expensive compared to wood logs. A furnace or furnace that requires electricity will not heat your home in the event of a power failure.

Operating principles of wood-burning boilers for private homes

Corn has the same btu per pound in tree form. Dried corn at 12% moisture weighs about 56 pounds per bushel. You can check the heat loss with the help of a heating specialist or your utility. It would take about 6 bushels per day to provide the same amount of heat as a gas or oil furnace, which would put out the same amount of heat on average.

This mixture passes through a nozzle, which is specially made of ceramic bricks and, getting into the second firebox, burns out. In a word, we get uniform and long-lasting combustion of our fuel.

The advantages include parameters such as:

Another consideration for homeowners who choose a corn stove. You must burn clean corn without penalty. You should have a connection with a corn farmer who is willing to sell a few bags or a load if needed. It is usually difficult to start a corn fire. Many require a lot of maintenance. Corn produces clinker that is more complex than coal, which is difficult to remove.

A wood stove, bottom wood stove, or multi-fuel wood stove provides warmth during power outages because they become gravity stoves, just like our grandparents. Biomass describes anything that grows, but in most cases, biomass heating refers to the burning of wood products, whether logs, chips, pellets or briquettes. As long as something grows in place of the harvested tree, as it almost always does, there is little to no greenhouse gas added to the atmosphere in the long run, unlike burning oil, coal or gas.

- The instructions that come with the equipment allow adjustments to be made over wide intervals;

- The resulting gases do not contain toxins and harmful substances;

- During operation there is practically no soot and ash;

- Almost complete combustion occurs;

- High efficiency– no less than 85%.

The disadvantages are the high price of this equipment and the difficulty of DIY installation.

How does biomass heating work?

This section refers to the most effective and practical ways using wood as an alternative to traditional central heating systems. Stoves can protrude into the room or be "drop-in" or "cassette" varieties that are flush with the wall. Automated pellet heaters - These are manually filled with wood pellets every few days and controlled by a timer and thermostat to warm the room as needed. Some can only operate on pellets, which are often fed through flexible pipe using a suction pump, while others may use chips or granules, with a powerful auger between the silo and the boiler.

What is the difference between pellet chips and logs

The main pros and cons of the three types of fuel are as follows.Boilers with built-in water circuit

Such equipment is a new word in heating engineering. They differ from conventional units in modified versions of their design. The latter includes a water circuit. Such units can not only heat the building, but also supply it with hot water.

The price of such equipment with a water heating circuit is higher than that of conventional boilers (conventional equipment costs about 29,000 rubles). But the high cost is justified by the wide functionality and use of high-quality materials for manufacturing.

Magazines - Magazine systems have fewer wearing parts and are simpler and less expensive. The advantages of chip systems are that they require much less regular intervention than logs, which can be left alone for one month, and that they can be locally sourced, making you independent of global energy markets and price fluctuations.

Features of different designs

They are ideal for landowners with commercial forestry operations near their homes, as the use of low-cost wood for heating can justify the cost of thinning and other beneficial forest management operations. Pellets - wood pellets - are a highly processed product, very dry and dense, a bit liquid-like and occupying a quarter of the area of a chip with equivalent heat content. The blower truck should be located approximately 15m from the pellet store, while the chip trailer should be able to dump the entire lip load into a hopper a few meters from the boiler room.

Modern boilers have compact dimensions, high power and versatility. They are well suited for any heating system. In addition, such devices can be installed both in a private home and in a large industrial building, since the characteristics of the boilers guarantee this.

Briquettes are very large pellets, typically the size and shape of a large tumbler, that are an environmentally friendly and lightweight alternative to logs, home charcoal or anthracite nuts for use in open fires or stoves. When considering which biomass boiler system is most suitable for your home, the main issues to consider are.

Magazines and chips are too bulky to transport more than a few miles economically, while pellets can be shipped worldwide, making them a global commodity without impact great influence on their volumetric value or impact on environment. Log systems should be able to store three years of fuel close to the boiler room, chip silos should be at least 30 m3, and can tanks should be at least 10 m3. Ideally, there will be a 25 m2 area for the boiler installation, as well as next to the fuel store . The tablet bin can be located up to 15m from the chip boiler store structure - there are many ways to lift chips into the above ground chip silo using a blower or high speed augers or conveyors. However, this is all due to the fact that transport company, conducting long time, goes up to an hour, slowly loading its load into the trough, which adds to the energy expended. These systems usually contain a lot of noise and dust. It is therefore strongly recommended that the added investment be made in buried or partially buried silo, which allows vehicle tip the load over the lip and quickly move away.

- Fuel Supply - Fuel supply must be reliable for the foreseeable future.

- A boiler with pellets or shavings must have at least 25 liters per kW.

The problem of gasification in our country is particularly acute. To date, only 65% of Russia's territory has been gasified, while the remaining residents are forced to use alternative ways heating. For many people, firewood, coal and other solid fuels are the only way to heat their home, even in spartan conditions. So the question of whether a wood heating boiler is relevant today is not relevant in itself.

But before we move on to discussing this unit, it is worthwhile to dwell in detail on the types of solid fuels, and which type is more rational.

Types of solid fuels

There are the following main types of solid fuel:

- wood - firewood, waste from the wood processing industry, braces and pellets;

- coal;

- oil shale.

Tree

Firewood was and is the main source of heat. The most preferable are hardwoods, which burn longer and have a higher CPV. Pine and coniferous ones are cheaper, but, accordingly, the efficiency is lower and there is more ash.

Harvesting firewood also causes certain difficulties, while a cube of wood costs from 3,000 rubles. For heating a house of 80-100 sq.m. for winter, 5-6 cubic meters are required. forests.

Modern materials - braces and pellets are more profitable both in price and in terms of calorific value. They are produced from waste from the wood processing industry by pressing with the addition of synthetic adhesives. On average per house is 80-100 sq.m. 3.5-4 tons of pellets are required for the winter at the rate of 4,000 rubles. ton. It turns out that this is 15-16 thousand rubles per season.

Coal

For heating, hard coal is mainly used, since brown coal has a high moisture concentration, large ash residues and a calorific value even lower than that of firewood. Coal dense, contains almost no moisture, while the calorific value is 6700 kcal per 1 kg, which is higher than that of wood. The cost of 1 ton of coal is 1,500 rubles; on average, 4 tons are needed to heat a house. The result will be 6,000 rubles, which is the most rational heating method of all of the above. It should be understood that coal requires specific storage conditions. It produces a large ash deposit; a wood-burning boiler for heating will have to be cleaned daily.

Rules for the organization and location of wood heating

Even in small house a wood-burning boiler for heating should be located in separate room- a boiler room, where, among other things, there is space for storing equipment.

When choosing a gravitational scheme for heating a house, when the property of water to expand when heating and contract when cooling is responsible for organizing the movement of the coolant, the boiler for heating the house is set at the lowest point of the system. If the boiler is responsible for the operation of the boiler, in particular for the movement of the coolant circulation pump, there are no restrictions on the installation of the unit.

If there are problems with the power supply in the house, it makes sense to install a small 12 volt circulation pump on batteries, the power of which is enough to force the coolant to move.

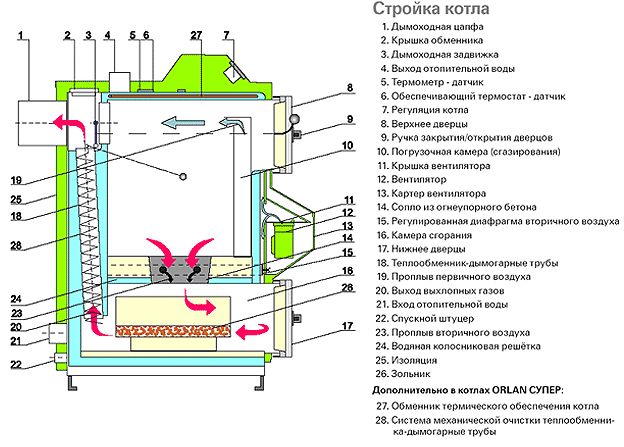

In order to understand exactly how the boiler works, you need to understand its design

Requirements for the room where they are installed wood boilers for home heating:

- ceiling height in the room is at least 250 cm;

- the volume of the room is 8-15 sq.m., where the cubic capacity is at least 15 cubic meters.

- facilities forced ventilation, ensuring the flow fresh air into the room in sufficient volume;

- the length of the chimney channel is from 400 cm, the diameter is at least 10 cm. Special attention given to the height of the pipe at the ridge of the building - at least 100 cm;

- the boiler must be freely accessible from all sides, the room itself must be uncluttered and well ventilated;

- interior decoration must be made of non-combustible materials;

- Firewood and coal should be stored separately in a dry, ventilated area.

Risk of occurrence reverse thrust is the main problem when using wood boilers for heating. To eliminate this defect, it is necessary to provide a special design for the chimney pipe.

Gravity systems for wood heating

In a house where gravity (coolant movement) is planned under its own pressure, the Leningradka system can be used. Its principle is to install one pipe from the boiler, to which radiators are connected in series. Not the most rational system, since the temperature of the coolant decreases as it passes through the radiators, and in the very last link of the system it is practically cold.

This problem can be solved by increasing the diameter of the output work, which will reduce the circulation speed and thereby reduce heat loss.

A similar scheme can only be used for small one-story houses.

In a two-story system, a branched gravity system is considered more rational, the peculiarity of which is the simultaneous connection of several separate circuits to the outlet pipe. Considering that a certain number of radiators will be connected to each of them, the heat will be distributed evenly. In this case, a gravity check valve must be installed, the task of which is to prevent the movement from returning to the outlet pipe.

The length of the circuits must be the same, otherwise the coolant will constantly circulate along a shorter circuit.

Types of solid fuel boilers

Wood heating boilers are divided into:

- classic;

- long burning;

- pyrolysis.

Classic boiler

This is a traditional type of wood-burning heating boiler, consisting of two chambers - an ash pan and a combustion chamber, made of heat-resistant steel, or less often cast iron. It is difficult to call such a boiler convenient - constant presence is required to maintain its operation, but in country houses, baths, small spaces short stay is excellent and quick way create comfortable temperature. Works on wood, coal, wood chips, pellets, etc.

Long burning

The operating principle of this design is based on limiting the access of oxygen during the combustion of wood. In fact, they smolder rather than burn, producing a higher calorific value with the ability to regulate the power output. What’s special is that one load of firewood lasts on average 20-22 hours, depending on the size of the combustion chamber.

Read more about this in our previous article.

Pyrolysis

It also belongs to the category of long-burning equipment, but differs in the principle of separating fuel into solid residue and pyrolysis gas. In two dependent chambers, the combustion process of both the residue and gas occurs simultaneously, due to which the efficiency increases to 85%, and the amount of ash decreases to 7-15%. There is only one drawback to such boilers - the need for practically chamber-drying fuel. Even 20% moisture content of firewood (the norm for furniture production), the boiler will not function normally.

You will find out in our article.

VIDEO: how a wood-fired pyrolysis boiler works

Read also...

- Federal State Budgetary Institution “National Medical Research Center for Psychiatry and Neurology named after V.

- Is it possible to legally avoid paying transport tax?

- Recipes for healthy dishes and drinks made from lingonberries

- Military registration Sample order on the organization of military registration