Pump for heating the house. Circulation pump for home heating: selection criteria

Most heating systems work fully with circulation pump(colloquially - pumps). The pump maintains the required fluid pressure in the heating circuit. This is its purpose - to keep the required pressure in the system, helping to overcome the hydro-resistance of the circuit elements (pipes, radiators) to the coolant, additionally moving it along the circuit. There are systems with several pumps: one in the heating boiler and one or two in the heating circuit. In the presence of a well-functioning circulation pump, it is not at all necessary to place the heating boiler in the lowest part of the heating circuit.

Design and types of circulation pumps

Most pumps have the following design:

- Frame with attached snail

- Are screwed to the snail circuit pipes

- Mounted in the case electric motor with control board and terminals for connecting electrical wires.

- Rotating part of the engine - rotor with nozzle(impeller) - moves water, sucking it in on one side and pumping it into the pipes of the circuit, on the other side

As a result of the work, some vacuum at the entrance pump and the desired pressure (compression) - at the outlet. All circulation pumps depending on design features are classified into two types:

- "dry" type (with a dry rotor);

- "wet" type (with a wet rotor).

![]() Pumps of the "dry" type are characterized by the fact that their rotor during operation itself does not come into contact with the working fluid of the circuit heating. It is securely isolated from it by a sliding seal - a ring. Such pumps have a fairly high efficiency - up to 75-85%, but operate with a certain level of noise. Such pumps are larger in size than their "wet" counterparts, and require special piping of the circuit. In addition, they usually need periodic maintenance. As a rule, these pumps are used in separate boiler housesproviding heat to several buildings or an industrial enterprise.

Pumps of the "dry" type are characterized by the fact that their rotor during operation itself does not come into contact with the working fluid of the circuit heating. It is securely isolated from it by a sliding seal - a ring. Such pumps have a fairly high efficiency - up to 75-85%, but operate with a certain level of noise. Such pumps are larger in size than their "wet" counterparts, and require special piping of the circuit. In addition, they usually need periodic maintenance. As a rule, these pumps are used in separate boiler housesproviding heat to several buildings or an industrial enterprise.

In wet type pumps, the rotating rotor itself is in contact with the fluid being pumped. heat transfer fluid, and the fixed part of the pump motor - the stator - is isolated from it. By interacting with the liquid, the necessary lubrication of the rotor parts and the noiselessness of the operation of the entire pump as a whole are achieved.

Pumps usually have a built-in step speed controller. Wet-type circulation pumps can operate for years, and sometimes decades, without requiring any maintenance. But they have low efficiency - only 50-65%. Pumps of this type have received most widespread in private domestic heating systems precisely because of their small size and noiseless operation. These aspects are one of a number of others when choosing a circulation pump for the heating circuit of your home. But there are other aspects to choosing a pump. We will consider them.

How to choose the right circulation pump?

Well-functioning pump in the heating system separate house or cottage must meet the following requirements.

With the last point, everything is clear. The smaller the pump and the quieter it runs, the better. From this point of view, circulation pumps are undoubtedly more suitable for installation in a heating system. wet type. Let's take a look at the other points.

Calculation of pump performance

The first three requirements for a pump are closely related and one depends on the other. Performance implies amount of distilled liquid, its consumption at a minimum pump load. To put it simply, the higher it is, the better.

There is a well-known formula her calculation: Q \u003d N / (t 2- t 1)

- Q- consumption (performance),

- N- power of the heating source (heating boiler),

- t1- temperature of the liquid in the "return" pipes of the heating circuit,

- t2- temperature in the flow part of the circuit, i.e. after the heating boiler.

In calculations, the value of t1 is taken within +60 ÷ +70С°, and the value of t2 - +90 ÷ +95С°. This formula allows you to approximately choose the parameters desired pump. It is generally accepted that for 10 meters of the length of the circulation ring of the circuit, you need about 0.6 meters of pump head.

There are already calculated thermal standards. It is considered: for warming up 10 sq. meters of the room requires 1 kW of heating boiler power. If you take thermal power one section of 200 W, then 10 sq. meters will require 5 sections. Usually taken small stock in the form of 1-2 sections. The pump must be able to supply water to all radiators in the building

Pump pressure

The pump pressure refers to the level to which the pump can raise the water in the heating system. It is measured in meters of water column or in atmospheres. This value is usually indicated in the documentation for the pump and on the pump itself(special tag).

Consider GRUNDFOS pump UPS 25-40.

Consider GRUNDFOS pump UPS 25-40.

The manufacturer is quite well known. The number 40 indicates the height of the coolant rise - 4 meters. Which corresponds to 0.4 atm. pressure. It is for this value that you need to select the pump in the first place for your system. What does the number 25 mean? It denotes the diameter of the connected pipes - 25 mm (1 inch). Typically, 25 mm and 32 mm (1.25 in.) pipes are used to connect the pump. Therefore it should look at the full name of the pump- it must match the diameter of the pipes (adapters) in your heating system. Usually, the power consumption is also indicated on the pump in different modes, the number of revolutions and the direction of movement of the rotor and coolant.

External factors influencing the operation of the pump

And, of course, the operation of the pump is affected external conditions. Temperature environment to a greater extent affects the amount of heat needed to heat the room, and hence the operation of the pump. In some rare cases, it also affects the operation of the pump itself - a “frozen” pump does not work like a “warmed up” one. By the way, the pump will start to overheat when it is not right choice- he can can't handle the overload. Therefore, when buying it, you should know the parameters of your heating system and boiler.

The larger the diameter of the pipes - the more water in the system, the more powerful the pump is needed. In addition, the coolant from an antifreeze liquid has a viscosity that is different from the viscosity of water, so the pump should also be selected more efficient and reliable. Fortunately, the choice of circulation pumps is quite large - you can choose the right one for almost every heating system.

From the author: Of course, the pump must be able to handle the load. But you need to take into account the fact whether it will work constantly, or whether it will turn on only at the right intervals. If the circulation pump is planned to be turned on only to feed the heating system and to slightly adjust the pressure, it is not necessary to choose a powerful high-performance pump of the brand. The Wilo N. O. -25/4 pump installed in my basement (see photo) turns on every 3-5 months for 1-2 minutes to raise the pressure by 0.1-0.5 atm. But then again: in a wall-mounted gas boiler, I already have a built-in pump that works all the time. Therefore, all factors must be taken into account.

If your pump will work in tandem with the natural circulation circuit, then the load on the pump may be high. In this case, the greater its performance and pressure, the better. With the wrong choice, the pump may simply not be able to cope with the task assigned to it - it will poorly "push" the system, as a result, the batteries will be barely warm. And the pump itself can overheat and burn out. Also, do not put the pump on 1 inch in 1.25 inch pipes through adapters. In some cases, it will not be able to provide the necessary pressure.

Another parameter of the pump is its consumed electric power . As a rule, it is small - from 50 to 200 watts. Great importance only available when the pump is constantly on.

Does the brand of the pump really matter?

There are many types of pumps from various companies on the market. Almost all of them have the same characteristics. They differ mainly degree of reliability and service life.

There are many types of pumps from various companies on the market. Almost all of them have the same characteristics. They differ mainly degree of reliability and service life.

The most common brands are Grundfos, Wilo, Wester, Wita, ELSOTHERM, Speroni. There are also a lot of different fakes from China or obviously Chinese products. The first two brands on the list are the most reliable. They are distinguished by excellent reliability and noiselessness. You can verify their work by ear only in close proximity (5-10 cm) or by placing your hand on them. Work for years without requiring any attention. But they have one small drawback - high price. Their price is about 2 times higher than for less well-known brands.

Other brands are considered average in terms of price / quality ratio. They work pretty well, problems with them are very rare. Their prices are in the middle range.

Advice: With the right choice, the pump will work without straining. Accordingly, the heating system itself will be distinguished by reliable, full-fledged work and there will be no interruptions in heat in your home.

The opinions of the owners constantly converge on Chinese products: sooner or later, these products begin to make noise, the rotor becomes loose, or the pumps simply burn out. They can work for a couple of months, or they can “hold out” for a couple of years. Their price is, of course, small.

Which one should you choose? Let's just say - never take Chinese pumps. If you do not mind overpaying for a brand - take Grundfos or Wilo. Do not want to overpay for the brand - buy a pump from the middle price category.

2016-05-10 20:32:07

Wow, I learned so much about pumps that my head is spinning. I have such a question, I want to buy a pump, but I only have money for Chinese, cheap. A friend offers to buy a used Grundfos company. Tell me whether it is worth contacting a used pump or not? Unfortunately there are no other options at the moment.

Gone are the days when water heating systems worked without pumps. And today, the efficiency of the heating system is increased precisely due to the installation of the pump. In addition, the room warms up much faster and fuel consumption is reduced. Connecting the pump to the heating system makes it possible to mount towel dryers, thermostats and use pipes of smaller diameter.

Advantages of connecting the pump to the heating system

hosts country houses with a decentralized water supply system, they face the problem of uniform distribution of heat over all heating circuits. For example, if water boils in the boiler, and radiators in distant rooms remain barely warm. In this case, it is recommended to look for the best means to solve the problem.

To improve circulation, there are two suggestions: installing pipes large diameter or updating the system by installing, or rather, inserting a pressure pump into the pipe. There are few people who want to take up the dismantling of pipes, if at the same time they are still walled up indoors. And the cost of the system itself, which includes pipes with a large diameter, is not always liked by the owners because of its high cost. And the price of the pump for the heating system is much lower.

Therefore, it becomes necessary to install a pressure pump. Circulating pumping devices are established on the heating systems working at all types of fuel - on firewood, coal, black oil. Updating the heating system by inserting a pump into the heating system will help you:

- To equalize the temperature in the pipes;

- Eliminate the appearance of air pockets that prevent the coolant from circulating normally;

- Make an increase in the area of action of your heating system.

Rules for choosing a pump for a heating system

For installation in a heating system, it makes no sense to purchase quite powerful pump, because you will not use it to its full potential. Also, it will make loud noises. The owner who buys the pump is advised to remember that the power of the device should be 10% higher than the value that was obtained as a result of your calculations.

The ability of pumping equipment to meet the needs of the heating system depends on many parameters. For example, on the diameter of pipes, maximum pressure, water temperature, coolant density:

- The flow rate of the coolant Q, which passes through any section of the thermal system, is calculated in the same way as the fluid flow rate for boiler equipment. That is, equate the value of the coolant flow rate to the boiler power parameters. With a boiler power of 20 kW per minute, about 20 liters pass through it.

- Radiators with a power of 10 kW will pass 10 liters per minute. When calculating the water flow in each ring of the heating system, take into account the power of the batteries.

- The fluid flow in the pipes is determined by the diameter of the pipelines. The smaller the diameter, the more resistance will occur in the path of the coolant.

The longer the pipeline, the more powerful the pressure pump for the heating system should be. This suggests that for every 10 meters of the heating system, 0.6 meters of pressure are needed from the pump. To ensure the productive operation of the ring at 100m, a pump head of 6m is required.

Classification of pumps for the heating system

Two types of pumps are used to move the energy carrier in the heating system:

- dry pumps. The rotor in such equipment does not come into direct contact with the energy carrier. When considering such equipment as an installation in a heating system, pay attention to some of its features. The power plant of the pump with the so-called "dry" rotor does not come into contact with the energy carrier during operation. The seal, located in the unit, is necessary for hermetic separation of the pump from the motor. The main advantage of these pumps is high efficiency- about 80%. Therefore, their use is advisable when constantly pumping a large volume of water. The equipment is used primarily for large retail premises, factories, plants and multi-storey buildings. Due to the rather strong noise that is generated during operation, such pumps are not suitable for private homes.

- Wet pumps. Their working part is in the water they pump. With the help of water, the engine is cooled, and all its components are lubricated. Electricity flows through the stator. Thus, it is well protected from the impact of the coolant by a stainless non-magnetic glass. The main advantages specific to injection pumps with a rotor in the water: for a long time exploitation, infrequent after-sales service, low noise, compactness and low weight, easily replaceable blocks, the pump is installed in the heating system directly on the pipes. Of course, among all the pluses there is a minus. Such devices demonstrate a rather low efficiency, which is 30-50%. A pressure pump with such a rotor is usually used in heating systems of houses and city apartments. It must also be remembered that pumps should not be used to supply drinking water and food-related issues.

Pump installation technology in the heating system

Preparatory work

For installation in a heating system, it is recommended to buy pumping equipment, which includes detachable threads. If there are no such parts, you need to buy yourself. Don't forget the deep filter. You should also prepare check valve to ensure the normal operation of the heating system.

After selecting a pump for a heating system, it is recommended to purchase a set special keys to install it, stop valves, a small piece of pipe. Its diameter should be the same as the diameter of the riser.

Choosing a location for the pump

When connecting the heating pump, choose such a scheme so that you can periodically service the system. It is desirable that you have an approach to it. If in earlier models of “wet” pumps, some parts could fail due to contact with water, now systems are produced in such a way that they are not at all afraid of water. Even at different high and low temperatures. This makes it possible to install pumping equipment on the return or supply pipeline.

To increase the pressure in the discharge section, it is necessary to install a pump near the place where the tank is connected in the section of the falling pipeline. Such a scheme makes it possible to create high temperatures in this area of \u200b\u200bheating. Before installing the pump in the heating system on the bypass pipe, check that the unit can withstand a strong pressure of high temperature water.

For more effective work equipment "warm floor" the pumping unit is placed at the site of the supply of heated water. Thanks to this, such a problem as the occurrence of air congestion will be eliminated. To restore the heating system with membrane tank put the bypass with the pumping unit on the return line. It is advisable to bring it closer to the expansion tank.

Pump installation rules

Proper installation of the pump in the heating system requires compliance with several rules:

- Install on both sides of the pumping equipment Ball Valves. They are required to ensure that the pump is dismantled if it becomes necessary to service or repair it.

- In the heating system, a filter is usually installed in front of the pump, which cleans the water from mechanical debris coming with the coolant.

- To remove accumulated air, install a special valve at the top of the bypass, which can be automatic and manual.

- When installing the pump for flushing the heating system, the direction indicated by the arrow on the pump must be observed. Remember that the direction must match the direction of fluid movement.

- In order not to damage the “wet” pump, if suddenly the motor is not completely immersed in water, the device is mounted horizontally.

- The terminals of the pump unit must be at the top.

- In the heating system for everything threaded connections you need to install gaskets, pre-treat with sealant.

- For safe use connect the pump for the heating system to a socket that has a ground connection. Before installing the pump, do not forget to carry out the steps that are related to the provision of grounding.

Pump installation principles

When inserting a pump into a heating system, pay attention to the following principles:

- First, drain the water and clean the system. The heating system, which was long-term operation, rinse several times, filling with water and emptying, to successfully clean off contamination.

- Next, embed the pump into a specially designated place, according to the plan. In this case, you need to look at the direction in which the energy carrier is moving. It is usually indicated by an arrow on the pump.

- After complete installation produce energy filling.

- Check the system for its functionality. If there are still some errors, then at this stage you need to correct them.

- Further, unnecessary air is removed from the system using the central screw. The correctness of the action is signaled by the outgoing water, which emerges from a special hole.

- De-aerate the manual pump every time before turning it on. Turn on the pump for 5 minutes and open the valve. This procedure is carried out several times.

- The pump turns on after filling the pipes with water. The system must be running. Remember that there should be no air left in the pipes.

- In order to automate the operation of the pump and protect equipment from improper operation buy an automatic pump. When connecting the pump to the mains, it is recommended to use an automatic fuse with a flag. It will perform two functions - a switch and a fuse. The fuse is installed at a distance of 50 centimeters or more from the boiler.

- To install an additional pump in a heating system where there is already one, keep in mind that it turns on after the thermal relay trips. In order for both devices to work synchronously, you need to connect the second pump, also connect to thermal relay. Also, an additional one can be connected to the main pump by means of a parallel connection.

Now you know how to install a circulation pump, and how to equip a heating system with two pumps. When taking into account all the rules and features when performing such work, you can forget about the problems of uneven heat distribution in the system and the formation of air gaps.

How to properly install the pump in a heating system that is already operating using natural circulation?

How to install a pump in a heating system designed for a new home? What shut-off valves can be used, and which ones should not be used? Let's try to find out.

Why you need a pump

Let's start with the main thing: we will find out whether it is necessary to install a pump for heating, if it has been working properly for many years without it. What will change?

pros

- The inertia of the system will sharply decrease. If, with natural circulation, at least an hour can pass between the ignition of the boiler and the noticeable heating of the radiators far from it, then with the forced injection of the coolant, the house will begin to warm up in a matter of minutes.

- The temperature of the heaters will even out. A feature of any gravitational system is the unequal heating of radiators closest to the boiler and farthest from it. The coolant, which circulates rather slowly, has time to cool down before it describes a full circle along the contour.

- If, during laying, they are somewhere mounted with a negative slope, this will not affect the circulation. Installing a pump in a heating system will dramatically increase the pressure drop, and the air pockets that are inevitable with a counterslope will no longer be a hindrance.

However: continuous murmuring with air in the circuit can be annoying. Functionality is functionality, but it is still better to take care of the ability to bleed air from everywhere.

Minuses

Do systems with a circulation pump have negative sides?

- The price of a kilowatt-hour of electricity is steadily growing, and the pump consumes it. Although a little - no more than 100 watts at maximum speed.

- If the heating system is designed only for forced circulation, the very first long power outage will prepare an extremely unpleasant surprise for the owner of the house. Overheating of the coolant by the boiler can cause the destruction of the heating circuit, and stopping the circulation can lead to subsequent defrosting.

conclusions

If with electricity consumption electric pump to do something is problematic by definition, then the second problem is solvable. Moreover, the solution is obvious: when designing a system, it is necessary to include in the project the ability to work due to natural circulation.

We put the pump

Position relative to the horizon

How to properly install the pump for heating in terms of its service life? Surely there are factors that can lead to accelerated wear of the mechanics.

The instruction is related to the peculiarities of the operation of the mechanical part of the device. The design of a heating pump used to create individual heating systems of moderate power implies continuous cooling of the rotor and shaft with bearings by a circulating coolant.

To prevent air pockets from leaving the bearings without lubrication and cooling, the motor shaft must be located strictly horizontally.

Water filtration

It is highly desirable to install a sump before the pump. Its function is to filter out the inevitable sand, scale and other abrasive particles that destroy the impeller and bearings of the circulation pump.

Since the diameter of the tie-in for the pump is usually small, an ordinary coarse filter is quite suitable. The keg intended for collecting suspensions should be directed downwards so that it will not interfere with the circulation of water, even when it is already partially filled.

Attention: on most filters, the arrow indicates the recommended direction of water circulation during installation. Yes, the filter will perform its function even if installed incorrectly; however, it will have to be cleaned much more often, and it will be much more difficult to remove ALL the sediment.

Location of the pump in the circuit

Formally modern pumps they work equally well both on the supply and on the return in any part of the heating circuit. However:

- The higher the coolant temperature, the lower the life of bearings and all plastic parts of the device. From this point of view, embedding it is still on the return pipeline, directly in front of the boiler.

- The expansion tank is recommended to be mounted on the section of the circuit with the coolant flow as close to laminar as possible. After the pump, the flow will inevitably be turbulent. Hence the second amendment: the circulation pump crashes in front of the boiler and after the expansion tank.

The optimal condition for an expansion tank is a water flow with a minimum of turbulence. In front of the pump, the jet in the circuit is almost laminar.

bypass

Do you remember our thoughts about the fact that it is highly desirable that the heating could work even when the electricity is turned off? Albeit with less efficiency?

How to install a heating pump with your own hands so that it does not interfere with natural circulation?

Let's think out loud for a bit. The gravity system is characterized, first of all, by the minimum difference between supply and return. Therefore, for an acceptable circulation rate, a minimum hydraulic resistance of the circuit is required.

What increases it?

- Turns and bends of the contour.

- ANY shut-off valve.

By the way: it is from this point of view that only modern ball valves should be used in any autonomous heating system. Unlike their screw counterparts, they offer minimal resistance to water flow in open form. To understand why this is so, take a look at this type of open valve.

- Reduced pipe diameter.

Conclusions?

- The pump cuts parallel to the main circuit without opening it. For the operation of the gravity system, the diameter of the circuit must be at least DN32; the diameter of the pump tie-in is much smaller.

- Between the tie-ins, a valve is installed that completely closes the main circuit when the pump is running. Otherwise, it will work, chasing water in a circle between the tie-ins.

- Before the pump and after it, valves are mounted that allow you to cut off the faulty device and dismantle it in the event of a malfunction without resetting the entire heating.

Such a tie-in scheme has a weak point - the need to manually switch from the pump to the bypass when the light is turned off. Yes, if you're at home, it's hard not to notice a power outage; but what if all your family members are away?

The solution is a check valve. In normal mode, it closes; as soon as the pressure in the main circuit before the pump has become greater than after it, the valve is open. As always, there are subtleties.

All spring check valves exhibit a noticeable head loss: the water must overcome the resistance of the spring. Which, of course, goes against our goals. Exit - ball valve installed horizontally. Its resistance to water flow will be minimal, as will the pressure required to open the valve.

Conclusion

The most common problem that owners of country houses have to face in the cold season is the uneven distribution of heat in the heating system. natural circulation hot water in the circuit is often not enough: the liquid in the boiler reaches the boiling point, and the batteries in the back rooms remain barely warm. Modernize existing system not so difficult - you just need to arrange a forced water exchange using special equipment. But where to install the circulation pump so that it works as efficiently as possible?

Correct and incorrect installation of the circulation pump

Functions of the circulation pump

Let's start with the fact that there are two ways to improve the situation with the heating of a private house - installing pipes of a larger diameter or installing a pump. The first option is used extremely rarely, since it involves a complete redesign of the system. It can only be considered when building a new house, and even then there are few who want to spend finances on an expensive network. It is much easier and cheaper to equip a new or existing system with a circulation pump.

What does the tie-in of the unit give:

- The inertia of the system is reduced, as a result of which the house warms up much faster.

- The temperature of pipes and radiators located at different distances from the boiler is equalized.

- The influence of the counter-slope is leveled, the problem of air jams will disappear.

Important! It is not necessary to design a heating system designed only for forced circulation. A prolonged power outage will cause the coolant to overheat.

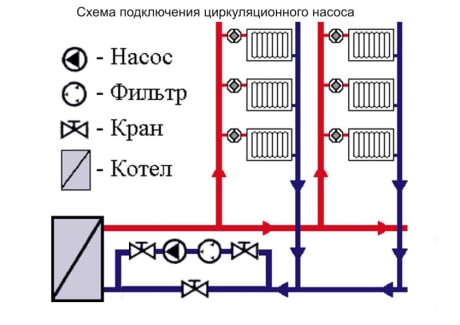

Circulation pump connection diagram

Location of the pump in the circuit

Where to install the circulation pump? Formally, modern equipment works equally well on any part of the circuit - both on the supply and on the return. However, it is better to take into account certain nuances:

- Heat reduces the resource of bearings and plastic elements of the device, so it is better to embed it on the return pipe (in front of the boiler).

- The expansion tank must be mounted on a pipe section with a uniform water flow, and the pump will inevitably add turbulence. For this reason, the equipment is recommended to be placed in front of the boiler, but after the expander.

Important! Before installing a circulation pump, make sure that it is capable of handling boiling water.

- To facilitate installation, it is better to purchase a device with a detachable thread. Otherwise, you will have to select adapters.

Among other things, you will need a deep filter, a check valve, valves, a bypass, a set of wrenches and a factory installation manual for the pump.

What is a bypass for?

Where to install the circulation pump so that it does not interfere with natural water exchange? The gravitational heating system is characterized by minimal differences between the supply and return pipelines, and for optimal speed, minimal hydraulic resistance is required. Any turns and bends of the circuit, stop valves and a decrease in the pipe clearance can worsen the situation.

Important! For autonomous system heating, only modern ball valves are suitable, which fully open the clearance in working order.

You can buy a ready-made bypass in the store

Bypass - a piece of pipe installed between the direct and return wiring - serves just to reduce Negative influence circulation pump for hydraulic resistance. The equipment crashes according to the following scheme:

- The pump is installed parallel to the main circuit, while the diameter of the bypass pipe must be smaller than the diameter of the main pipe.

- Between the tie-ins, a valve is mounted, which should close the main circuit. Otherwise, the equipment will distill water between tie-ins without directing it into the system.

- Protective valves are installed on both sides of the device. They allow you to cut off a non-working device and dismantle it if necessary.

- A check ball valve must be installed on the bypass - in the event of a power outage, it will transfer the system to natural circulation.

Important! If natural circulation is not provided, it is necessary to install a circulation pump with a source uninterruptible power supply. These can be external batteries powered from a backup source.

Installing a pump in an old heating system

Old heating system With natural circulation sooner or later begins to "sabotage" their duties. Rust, scale and sludge appear in the pipes, which reduce their clearance and prevent hot water from moving along a given contour. Before installing the circulation pump, it is necessary to carry out resuscitation measures:

- Replace old expansion tank to the membrane model. In this way, you prevent further corrosion and can reduce heat loss.

- Closed expansion tank must be equipped with a safety valve that will relieve emergency pressure when the system overheats.

- Thoroughly flush the entire pipeline by connecting it through hoses to the water supply. Take the time and effort - you need to wash as much rust and sludge as possible.

Professional flushing of the heating system

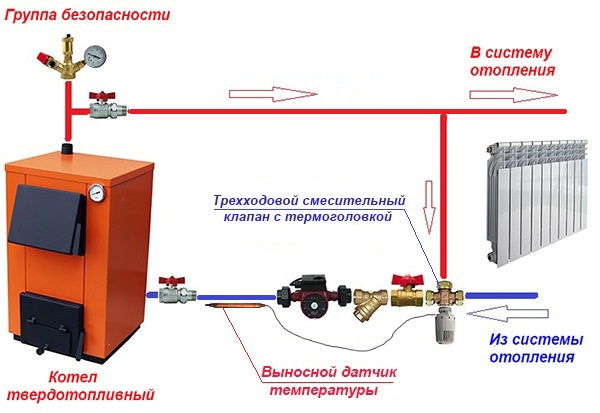

Important! If your heating system is running on solid fuel boiler, it is better to install the circulation pump on the return line so that it does not overheat from too high a temperature.

To check the correct installation of the equipment and evaluate its performance, the system is filled with water. The central screw on the body of the apparatus is opened to remove air pockets. As soon as water appears, the pump can be started.

Spend installation work you can do it yourself if you have sufficient knowledge and are confident that you can apply correct scheme installation. If you have any doubts, contact the experts. It is better to spend a small amount of money on calling an installer than to eliminate the consequences of amateur performance in severe frosts.

Video: installing a circulation pump

In order for the heated water to flow more cheerfully through the pipes, a circulation pump is installed in the heating systems of private houses. This solution provides tangible benefits, which we will briefly introduce to you. But the main issue that concerns homeowners and is highlighted in this material, - where it is better to put the pump and how to properly install it. After all, the main part of the disputes and doubts is caused just by the place of insertion of the unit. And at the same time we will figure out how to connect it to the house electrical network with your own hands.

30 years ago, so-called steam heating was widespread in private houses, where a heat carrier was used that circulated through pipelines and batteries by gravity, and a gas boiler or wood-burning stove served as a heat source. Pumps for pumping water were used only in district heating networks. When more compact units appeared, they migrated to private housing construction, as they provided the following advantages:

- The speed of movement of the coolant has increased. The heat generated by the boiler has become faster delivered to the radiators and transferred to the premises.

- Accordingly, the process of heating the house is significantly accelerated.

- The higher the flow rate, the more throughput pipes. This means that the same amount of heat can be delivered to the rooms through lines of smaller diameter. Simply put, pipelines have become half the size thanks to forced circulation water from the pump, which is cheaper and more practical.

- Highways can now be laid with a minimum slope and make arbitrarily complex and extended water heating schemes. The main thing is the correct selection of the pumping unit in terms of power and pressure generated.

- The household circulation pump for heating made it possible to organize underfloor heating and more efficient closed systems working under pressure.

- We managed to get rid of the ubiquitous pipes passing through the rooms and not always in harmony with the interior. Increasingly, heating communications are laid in the walls, under flooring and behind suspended (stretch) ceilings.

Note. A minimum slope of 2-3 mm per 1 m of the pipeline is needed to empty the network in case of repair or maintenance. Previously, it was made at least 5 mm / 1 m.

At pumping systems there are disadvantages, where without them. This is the dependence on electricity and its consumption by the pumping unit during heating season. Therefore, with frequent power outages, the circulation pump must be installed together with an uninterruptible power supply or connected to an electric generator. The second drawback is not critical, if you choose the power of the device correctly, then the electricity consumption will be acceptable.

For reference. Leading manufacturers heating equipment, such as Grundfos (Grundfos) or Wilo (Vilo) have developed new models of units that can save electricity. For example, if you buy and install an Alpfa2 circulation pump from the Grundfos brand, it will automatically change performance depending on the needs of the heating system. True, its price starts at 120 USD. e.

New generation products from Grundfos - models Alpfa2 and Alpfa2L

New generation products from Grundfos - models Alpfa2 and Alpfa2L Where to put the pump - for supply or return

Despite the abundance of information on the Internet, it is quite difficult for the user to understand how to properly install the pump for heating in order to ensure forced circulation of water in the system own house. The reason is the inconsistency of this information, which causes constant disputes on thematic forums. Most of the so-called specialists claim that the unit is placed only on the return pipeline, citing the following conclusions:

- the temperature of the coolant at the supply is much higher than at the return, so the pump will not last long;

- the density of hot water in the supply line is less, so it is more difficult to pump;

- the static pressure in the return pipe is higher, which makes it easier for the pump to work.

Interesting fact. Sometimes a person accidentally enters a boiler room that provides central heating apartments, and sees the local units embedded in the return line. After that, he considers such a decision to be the only correct one, although he does not know that in other boiler houses centrifugal pumps can stand on the supply pipe.

We answer the following statements point by point:

- Domestic circulation pumps are designed for a maximum coolant temperature of 110 °C. In a home heating network, it rarely rises above 70 degrees, and the boiler will not heat water more than 90 ° C.

- The density of water at 50 degrees is 988 kg / m³, and at 70 ° C - 977.8 kg / m³. For a unit that develops a pressure of 4-6 m of water column and is capable of pumping about a ton of coolant in 1 hour, the difference in the density of the transported medium of 10 kg / m³ (the volume of a ten-liter canister) is simply negligible.

- In practice, the difference between the static pressures of the coolant in the supply and return lines is just as insignificant.

Hence the simple conclusion: it is allowed to embed circulation pumps for heating both in the return and in the supply pipeline of the heating system of a private house. This factor will not affect the performance of the unit or the heating efficiency of the building.

Boiler room made by our expert Vladimir Sukhorukov. Convenient access available for all equipment, including pumps.

Boiler room made by our expert Vladimir Sukhorukov. Convenient access available for all equipment, including pumps. Exception - cheap solid fuel boilers direct combustion, not equipped with automation. When overheated, the coolant boils in them, since burning firewood cannot be extinguished at once. If the circulation pump is installed on the supply, then the resulting steam mixed with water enters the housing with the impeller. The further process looks like this:

- The impeller of the pumping device is not designed to move gases. Therefore, the performance of the apparatus is sharply reduced, and the flow rate of the coolant drops.

- Less cooling water enters the boiler tank, which causes overheating and even more steam.

- An increase in the amount of steam and its entry into the impeller leads to a complete stop of the movement of the coolant in the system. An emergency situation arises and as a result of an increase in pressure, a safety valve is activated, ejecting steam directly into the boiler room.

- If measures are not taken to extinguish the firewood, then the valve cannot cope with the pressure relief and an explosion occurs with the destruction of the boiler shell.

For reference. In cheap heat generators made of thin metal, the response threshold safety valve is 2 bar. In higher quality TT boilers, this threshold is set at 3 bar.

Practice shows that no more than 5 minutes pass from the beginning of the overheating process to the valve actuation. If you install a circulation pump on the return pipe, then steam will not get into it and the time interval before the accident will increase to 20 minutes. That is, installing the unit on the return line will not prevent the explosion, but will delay it, which will give more time to fix the problem. Hence the recommendation: it is better to install pumps for wood-fired and coal-fired boilers on the return pipeline.

For well-automated pellet heaters, the installation location does not matter. You will learn more information on the topic from the video of our expert:

Installation schemes in various types of systems

To begin with, let's specify the place where to put the flow pump, which ensures the circulation of water through the boiler and forcibly directs it to the radiators of the heating system. According to our, whose experience is trustworthy, the installation site must be chosen in such a way that the unit is convenient to maintain. At the supply, it should be after the safety group and the fittings cutting off the boiler, as shown in the installation diagram:

In order for the equipment to be removed and serviced, shut-off valves must be installed

In order for the equipment to be removed and serviced, shut-off valves must be installed On the return line, the pump must be placed directly in front of the heat generator, and in tandem with a filter - a mud collector, so that you do not have to buy and install extra taps. The piping scheme of the pumping unit looks like this:

Use 1 less tap for return mounting

Use 1 less tap for return mounting Recommendation. The circulation pump can be installed in this way both in closed and in open system heating, there is no big difference. The statement applies to collector system, where the coolant moves to the radiators through separate pipes connected to the distribution manifold.

A separate issue is an open heating system with a circulation pump, capable of operating in 2 modes - forced and gravity. The latter is useful for homes where power outages often occur, and incomes do not allow owners to buy an uninterruptible power supply or generator. Then the apparatus with shut-off valves must be placed on the bypass, and a tap should be inserted into a straight line, as shown in the diagram:

This scheme can work in forced and gravity mode.

This scheme can work in forced and gravity mode. An important point. On sale there are ready-made bypass units with a pump, where instead of a tap on the duct there is a check valve. Such a decision cannot be called correct, since the check valve spring type creates a resistance of the order of 0.08-0.1 bar, which is too much for a gravity heating system. Instead, you can use a petal valve, but it must be placed only in a horizontal position.

Finally, we will explain how to install and connect the circulation pump to a boiler that burns solid fuel. As mentioned above, it is better to put the unit on the line going from the heating system to the heat generator, which is shown in the diagram:

As you can see, the piping uses a pump connected to the boiler circulation circuit with a bypass and the important role of these piping elements is described in detail

Installation rules

The design of a household circulation pump from any manufacturer provides for its fastening to pipelines or shutoff valves by means of union nuts (American women). This allows you to quickly dismantle it if necessary, for example, for replacement or repair. When installing the pump unit, observe the following recommendations:

- Place the device on any sections of pipelines - horizontal, vertical or inclined, but with one condition: the rotor axis must be in a horizontal position. That is, installation "head" down or up is unacceptable.

- Please note that plastic box with electrical contacts was on top of the case, otherwise it will be flooded with water in case of an accident. Yes, and it will not be easy to maintain the product. This is easy to achieve: unscrew the screws securing the casing and turn it to the desired angle.

- Be aware of the direction of flow indicated by the arrow on the body.

- To ensure that the product can be removed without emptying the system, install shut-off valves before and after it, as shown in the diagrams in the previous section.

A visual aid in which position the pump unit should stand

A visual aid in which position the pump unit should stand Advice. It so happened that the load from the weight of the circulation unit will fall on 1 or 2 ball valves (depending on the orientation of the site in space). Hence the recommendation: do not save money and buy high-quality shut-off valves, whose body will not crack over time from mechanical stress.

About installing additional units

Typically in a closed or open system radiator heating where a single boiler serves as a heat source, it is enough to install one circulation pump. In more complex schemes, additional units are used for pumping water (there may be 2 or more). They are placed in such cases:

- when more than one boiler plant is used to heat a private house;

- if a buffer capacity is involved in the piping scheme;

- the heating system has several branches serving various consumers - batteries, underfloor heating and an indirect heating boiler;

- the same, using a hydraulic separator (hydraulic arrow);

- for organizing water circulation in the contours of underfloor heating.

Proper piping of several boilers operating on different types fuel, requires that each of them has its own pumping unit, as shown in the diagram of the joint connection of an electric and TT boiler. How it works is described in

Piping of an electric and TT boiler with two pumping devices

Piping of an electric and TT boiler with two pumping devices In the scheme with buffer capacity it is necessary to install an additional pump, because at least 2 circulation circuits are involved in it - boiler and heating.

Buffer capacity divides the system into 2 circuits, although in practice there are more

Buffer capacity divides the system into 2 circuits, although in practice there are more

Separate story - complex scheme heating with several branches, implemented in large cottages on 2-4 floors. Here, from 3 to 8 pumping devices (sometimes more) can be used, supplying the coolant floor by floor and to different heating appliances. An example of such a circuit is shown below.

Finally, the second circulation pump is installed when heating the house with water warm floors. Together with the mixing unit, it performs the task of preparing a heat carrier with a temperature of 35-45 °C. The principle of operation of the circuit below is described in detail.

Reminder. Sometimes pumping devices do not need to be installed for heating at all. The fact is that most electric and gas wall-mounted heat generators are equipped with their own pumping units built into the housing.

Connecting the circulation pump to the mains

There are several ways to connect the power to the machine:

- through a conventional differential machine;

- thermostatically controlled;

- connection to the network together with an uninterruptible power supply unit (UPS);

- power supply of the unit from the boiler automation.

Warning. Often, homeowners simply plug the pump into a regular outlet by connecting the wires to the purchased plug. We cannot recommend this approach, because connection without grounding and a safety device is dangerous. In the event of a malfunction with the device or filling it with water, you risk an electric shock.

Scheme with a differential automaton

Scheme with a differential automaton The first connection scheme is quite simple and any user can assemble it with his own hands. Requires a differential circuit breaker rated 8 A, wires and contacts. Connect to ground in this circuit as well as in all others.

To automatically stop the movement of the coolant when cooled to certain temperature, used circuit diagram connection of a circulation pump with a thermostat. The latter is attached to the supply pipe and breaks the power supply when the water temperature drops below the set value.

Accession phase wire to the pump through the contact thermostat

Accession phase wire to the pump through the contact thermostat Attention! So that the thermostat does not lie and turns off the circulation in time, it must be attached to the metal section of the line. Polymers do not transfer heat well, so when mounted on plastic pipe the device will not work properly.

There are no difficulties in connecting the power supply through the UPS, for which the latter has special connectors. It is also worth connecting the heat generator itself to them, if it needs electricity. But connecting the pump to the boiler control panel or to its automation is a more complicated procedure. Here it is desirable to have knowledge and skills in the field of electrical engineering.

The boiler is also connected to the uninterruptible unit if it needs electricity.

The boiler is also connected to the uninterruptible unit if it needs electricity. At what speed should the pump in the heating system operate

The purpose of forced circulation is efficient heating at home due to the reliable delivery of heat to all consumers of the system, up to the farthest radiator. To do this, the pump unit must develop required pressure(otherwise - pressure), which is ideally calculated by design engineers according to the hydraulic resistance of the pipeline network.

On most household pumps there are from 3 to 7 rotor speeds, due to which the performance and the generated pressure can be increased or decreased. In order not to torment you with hydraulic calculations, we offer the following method for selecting the optimal speed:

- Find a laser surface thermometer (pyrometer). Bring the heating system into operation.

- Measure the surface temperature of the pipe at the boiler inlet and outlet.

- If the temperature difference is more than 20°C, increase the rotor speed. Repeat measurement after 30 minutes.

- If the temperature difference is less than 10 °C, the water flow rate must be reduced. The task is to achieve a delta between supply and return of about 15 ° C.

3 rotation speeds is a minimum, sometimes 7 or more

3 rotation speeds is a minimum, sometimes 7 or more Advice. Do not switch the pump to a different circulation speed "on the fly". Disconnect it from the network, move the regulator to another position, and then put it back into operation.

A pyrometer can be dispensed with when thermometers are installed on the supply and return lines. If the adjustment limits do not allow you to enter the range of 10-20 ° C temperature difference, your system is not working efficiently due to an incorrectly selected circulation pump. Too much cold water in the return line gives an increased load on the boiler and fuel consumption. Too hot water means that it flows too fast and does not have time to transfer heat to the heaters.

For reference. The leading European brand Grundfos (Grundfos) offers the latest generation of circulation units Alpfa3, which can independently select performance depending on the load and in this way adapt the work to changing conditions. With their help, you can even balance the heating system, as our expert will tell you in the next video:

Conclusion

Now you know exactly how to properly install the circulation pump in the water heating system and connect it to the mains country house. This will keep you from committing different kind mistakes leading to minor and major troubles. Again, you can do the installation and piping of the unit with your own hands. The only difficulty is to embed it into steel pipelines connected by welding. But even here there is a way out: find a set of lerok for manual cutting pipe thread, cut a piece of pipe with a grinder and mount the pump assembly. The main thing is to have the desire and time to fulfill it.