Boilers on solid fuel of long burning pyrolysis. Long burning pyrolysis boiler. Homemade pyrolysis boilers for long burning

When restoring or building a small house in the countryside, many people often think about alternative uses. furnace heating. The issue of not only achieving maximum comfort, but also rational economical spending becomes relevant. natural resources. To date, the best alternative to solid fuels are pyrolysis boilers. long burning. The question immediately arises, why exactly such heating equipment, and what does “pyrolysis” have to do with boilers?

Solid fuel boilers with pyrolysis combustion are otherwise referred to as gas generators. The main advantages of such boilers are the ability to control the power of work and high efficiency, which can reach 85%.

A distinctive feature of solid fuel boilers with pyrolysis combustion is that they burn not only firewood, but also wood gas released under the influence of high temperature. With such combustion, very little ash remains and there is practically no soot. Pyrolysis combustion provides a high temperature in the furnace bunker, as a result of which not only wood gas is released, but also its further passage through the nozzle. The gas burns with a clean, beautiful white or yellowish flame.

The disadvantages of pyrolysis boilers include their higher price compared to traditional solid fuel boilers, as well as the need for electrical power. Any type of wood, wood briquettes and wood waste, the moisture content of which does not exceed 20%, can be used as fuel for gas-generating boilers.

The indisputable advantage of pyrolysis boilers is the ability to work throughout the day with a single fuel load. Of course, the duration of work with one tab is determined by a number of factors:

- Air temperature outside

- Set room temperature level

- Fuel moisture

- Degree of building insulation

- Conformity building codes heating system

In any case, pyrolysis boilers are much more efficient than traditional ones. solid fuel boilers. The question immediately arises, what is the basis of such a statement?

First of all, when burning firewood, especially if it is waterlogged, it is not possible to achieve a high temperature, which is quite possible when burning wood gas. In addition, much less secondary air is required to burn the gas, resulting in a higher temperature and improved fuel combustion efficiency. The possibility of automating the process is similar to the automation of liquid fuel and gas boilers, making it much easier to control the combustion process of pyrolysis gas.

How does it work

The principle of operation of a gas-generating boiler is based on the dry distillation of fuel (or pyrolysis combustion), the meaning of which is that with an oxygen deficiency under exposure conditions high temperatures splitting of dry wood occurs with the release of the volatile part. It is this volatile part that is called pyrolysis gas, and the solid residue is called coke or charcoal.

Pyrolysis of wood occurs in a wide temperature range from 200 to 800 degrees. The process is exothermic in nature, that is, it proceeds with the release of heat, as a result of which there is an improvement in the drying of the fuel and its heating, and the heating of the air that enters the burner zone is also performed.

Thermal energy is obtained as a result of the combustion of pyrolysis gas released at a high temperature, which is mixed with atmospheric oxygen. It should be noted that during the combustion process, the pyrolysis gas is in contact with active carbon, due to which there are practically no harmful impurities in the flue gases at the outlet of the boiler.

In general, it can be said that the main components of the flue gas at the exit are water vapor and carbon dioxide. At the same time, emissions of carbon dioxide into the atmosphere are three times less than during the operation of similar boilers operating on coal or wood.

At pyrolysis combustion a minimum of ash and soot is formed, which reduces the cost of operating the equipment, which is associated with more infrequent cleaning.

Something about fuel

To provide long-term operation pyrolysis boiler and its operation with maximum power, the most dried wood should be used as fuel.

For example, 1 kg of wood with a moisture content of 15-25% has a calorific value of about 4 kW / h, the same amount of fuel with a moisture content of 25-40% - 3 kW / h. If the moisture content of wood exceeds 50%, then 1 kg of wood will have a calorific value of less than 2 kWh.

Obviously, the amount of energy released is largely determined by the moisture content of the wood. Excess moisture causes low heating, poor combustion, and smoke. Regular use of “wet” firewood as fuel significantly reduces the life of not only the chimney, but also the boiler itself. The power of the boiler can be halved, at the same time, the consumption of low-quality fuel can have a similar indicator only in the direction of increase.

The scheme of operation of the pyrolysis boiler can be simplified as follows:

- Loading firewood or wood waste into the preflow

- Thermal sublimation of fuel

- Supply of generator gas to the combustion chamber

- Flue gas heat recovery by heat exchanger

- Control of the air supply to the pre-stream required for the pyrolysis process

Price

From the above material, it becomes obvious that the pyrolysis boiler is a modern and effective solution heating system issue. Despite the mass of such obvious positive aspects of the operation of pyrolysis boilers, many are still stopped by their high price.

The price of the most primitive domestic gas-generating boiler is more than a thousand dollars, and the cost of imported analogues is even higher. So it turns out that the main task of designers is to make such effective equipment more affordable.

Can be DIY

If there is no money to buy a pyrolysis boiler, then this is not a reason to refuse such equipment. You can order the manufacture of a boiler by specialists, which can be a little cheaper, or you can try to make such a boiler yourself. True, for this you will have to get drawings, and on the Internet, unfortunately, there are not so many of them.

Blago boiler

Inventor Blagodov Yu.P. speaks very flatteringly about his offspring - the Blago boiler, giving a lot of arguments in favor of his invention.

Pyrolysis boilers Blago differ from their standard counterparts in the following characteristics:

- Increased loading chamber size

- Enlarged chamber doorway

- Ability to work with both a smoke exhauster and natural draft

- No direct pull gate

- No manual adjustment

- The presence of a plate gas-tube heat exchanger

- Heating of the air supplied to the combustion chamber

- Comfort and ease of cleaning

- More high efficiency

- High-quality steel is used for the manufacture of the boiler

- The lining is made using high-quality fireclay

- No smoke when reloading fuel

- Excellent price-quality ratio - technical parameters

The Blago pyrolysis boiler is not only adapted to weather conditions and the needs of our customers, but can also confidently compete with imported counterparts, often surpassing them in many technical, physical and economic parameters.

View of the finished Blago boiler

The pyrolysis boiler Blago is very similar to its Polish prototype IRLEH, the difference is only in the improved quality of the afterburning of pyrolysis gases, which is realized by supplying heated air.

Blago boiler size for houses from 100 to 200 sq.m.

Thanks to the combination of the ignition valve with the loading door, as well as the installation of an additional hinged door, it was possible to significantly increase the fire safety of the equipment, which is due to the impossibility of the release of pyrolysis gases and their self-ignition outside the boiler. Thanks to this, you can not worry about the operator's inattention, even if he does not open the kindling chamber before opening the loading door, pyrolysis gases will still not be able to enter the room. This is due to the fact that when the loading door is open, the hinged door will play the role of a fuse, which will prevent the spread of gas into the room and direct them towards the chimney.

System fire safety The device is designed in such a way as to prevent any abnormal situation that may arise through the fault of the operator. Logs from half a meter long can be placed in the combustion chamber, while the duration of the boiler on one tab can reach 10 hours.

Boiler "Teplolov"

Another type of heating water-air boilers are boilers of the "Teplolov" type. These are fairly simple and reliable devices that are designed to organize the heat supply of buildings. for various purposes. Waste lump wood, pressed briquettes and wooden logs can be used as fuel. At the same time, the length of the logs should be in the range of 0.38-1.0 m, their diameter should be not less than 0.1 m and not more than 0.25 m.

The minimum allowable size of briquettes is 3/30 cm. Small wood waste, including sawdust, can be burned together with logs, while their amount should not exceed a third of the volume of the loading chamber.

A large loading door and an increased chamber volume reduce labor costs for chopping firewood. Wood can be used as fuel, the moisture content of which does not exceed 30%.

The type of arrangement of the Teplolov boilers, as well as the principle of fuel combustion, has some differences from standard solid fuel boilers. The operation of the equipment is based on the principle of thermal decomposition of fuel. During the process in the loading chamber, against the background of oxygen deficiency and high temperature, pyrolysis gas is released, the combustion and heat transfer of which are similar to the operation of the Blago pyrolysis boiler presented above. The efficiency and CO2 emissions are also close to those of Blago boilers.

The design of the boiler "Teplolov"

The boiler "Teplolov" consists of two chambers located one above the other. Fuel is loaded into the upper chamber, which is a fuel bunker, and here it burns with the release of natural gas.

It is thanks to gasification in the first chamber that the wood is dried and the air is heated, which is then sent to the combustion chamber. In the lower chamber, pyrolysis gas is burned, and ash is also accumulated here. The chambers are interconnected by a special gasifying nozzle. The boiler output is controlled by the dosage of secondary air blowing.

The positive characteristics of the Teplolov pyrolysis boilers include a fairly precise adjustment, which is not often implemented in standard solid fuel boilers. A sensitive temperature controller makes it possible to accurately set the temperature of the coolant. Heating the air entering the combustion zone makes the operation of the boiler more economical, and pyrolysis combustion minimizes the amount of waste and increases the life of the equipment. The power of the boiler can reach 40-50 kW, and the operating time on one load is determined by the quality of the fuel and can reach 12 hours.

As a heat carrier, you can use both water (water-heated floor or traditional hanging batteries) and air. The latter option looks more promising, as it allows you to warm up the room more quickly. Another positive point can be considered the absence of the need to deliver the coolant and reduce the cost of ensuring the tightness of the pipes.

Coolant leakage will not bring any losses, the system can be stopped and resumed at any time. This aspect is quite relevant for owners country houses and cottages, where people do not live permanently, because the air in the pipes cannot freeze, which often happens with water, and destroy the heating system.

The movement of the coolant is based on natural circulation – hot air rises up the pipes, and the influx of cold air occurs by gravity.

The finished boiler "Teplolov" costs about 1400 euros. If you have drawings that you can purchase from the creators of these boilers and do the work yourself, this figure can be halved.

Long-burning pyrolysis boilers are perfect for heating a residential building. The first thing to note is their versatility. Today there are models with different designs. Their characteristics and dimensions are very different.

In maintenance, these devices are simple and do not force the owner to make great physical efforts. Additionally, it should be noted that pyrolysis boilers are economical. Wood in them can be used with a moisture content of up to 50%.

Boiler device with controller

A distinctive feature of this type (the scheme of a long-burning pyrolysis boiler is shown below) can safely be called a volumetric chamber, which is designed for fuel combustion. It closes with a metal door. In some cases, it is installed with a window. In such a situation, it is possible to observe the combustion process and, if necessary, report firewood for the formation of pyrolysis gas.

Next to the chamber there is an entrance that connects the device to the house's plumbing system. A special air supply mechanism is hidden behind the side panel of the boiler. With it, you can adjust the traction. The damper of the unit is installed under the air drive. The control unit is located at the top of the structure, and the heat exchanger is located under the casing and is reliably protected. The device is equipped with a fan for exhaust. It should also be noted the branch pipe, which is necessary to remove excess pyrolysis gases. The design of the device itself can be equipped with wheels that are needed to transport the boiler.

Fused Models

This kind of long-burning pyrolysis boilers, as a rule, have a double combustion chamber. In this case, the device is equipped with a special sensor that controls traction. The fuse itself is mounted on the side panel of the device. For air supply there is a special network that connects to the tee. The outer contour of the boiler has a protective cover. This type of device is connected to the plumbing system through special connectors that are located at the bottom of the structure. The main frame of the boiler supports the ash pan.

How to make long-burning pyrolysis boilers?

The drawings will help you make your own this device. Although this is quite difficult and requires some experience. In order to build home-made long-burning pyrolysis boilers, you first need to look for a combustion chamber. As a rule, they are made of steel. Directly the design of the device can be used cast iron. In this case, you will need to weld additional supports. An ash pan should be installed under the boiler chamber. At the same time, it must be protected by a net. The air damper is generally made in a small size. In this case, it will be easier to adjust the traction.

For air supply, a drive system must be installed. It consists of two plates that are connected to each other. The boiler heat exchanger must be installed last. The door, like the combustion chamber, should be made of steel. In this case, it will be able to withstand large thermal loads. A fan is installed next to the firebox. As a result, part of the pyrolysis gases will be removed from the boiler.

Consumer reviews about Bosch boilers

The Bosch company is quite famous, and its products are different good quality. The average power of the boilers is at the level of 80 kW. This is enough to heat a residential building with total area up to 900 sq. m. Heat exchangers in many models are made of cast iron. The thickness of the metal is quite large. Firewood no longer than 40 cm is used as fuel for boilers. The manufacturer provides manual loading in all models. The combustion chamber depends on the modification of the device.

The consumer has the opportunity to choose any size for their convenience. On average, chambers are produced with a total volume of up to 400 liters. Management in all models is mechanical. In order to control traction, a lever is installed on the top panel. In offline mode, the boilers are able to work for about 7 hours. To connect to the water supply, the device has two 70 mm connectors. According to the owners, you can load large firewood. In maintenance, boiler models are quite simple. In order to clean the ashes, you just need to open the door and take out the drawer. This should be done at least once a week.

Features of the Atmos models

For large cottages, these long-burning pyrolysis boilers are ideal. They differ primarily in their design. The thickness of the metal itself is insignificant, but there are additional stops. No special tools are required to install the boiler. To connect the device to the water supply system, there are standard threaded connectors. Of the shortcomings, it should be noted rather poor management. In some cases, the draft regulator may be stuck. As a result, the air flow cannot be controlled. There are still certain problems with the ash pan in early models. It is rather difficult to pull out, and the doors sometimes do not close well.

On one load of wood, the boiler is on average able to work for about 5 hours. Some models are equipped with an auto-off system. Also, consumers were pleased with high-quality cooling heat exchangers. Models of the DC series are best suited for home heating. According to experts, "Atmos DC100" is the best long-burning pyrolysis boiler of this company.

What do they say about boilers "Teplodar"?

Russian long-burning pyrolysis boilers of the Teplodar company are distinguished by their performance. Their efficiency reaches 90% in some cases. The average power of the units fluctuates around 14 kW. This makes it possible to heat rooms with a total area of not more than 140 square meters. m. Reviews indicate that the maintenance of the model is quite simple. To connect the device to the water supply system, branch pipes are provided at the bottom of the structure. Management in many models is mechanical.

Of the shortcomings, consumers note bad doors. In this case, this greatly complicates the loading of the camera. At the same time, firewood is suitable only up to 30 cm in size. You can choose a suitable boiler in size. The auto-off system is not installed on all models. The frames in many modifications are durable, but the wheels for transportation are of poor quality. As a result, the oven may be unstable.

Expert opinions on the products of the company "Protech"

Long-burning pyrolysis boilers of this brand are famous for their powerful ventilation systems. In this case, gases will never enter the room. There is enough fuel for the device for for a long time. Control units are installed in different modifications and differ in their characteristics. If we consider the boilers of the first series, then they are characterized by standard schemes. The damper can only be adjusted in two positions.

Thus, it is rather problematic to control the air flow and adjust the temperature in a residential building. If we consider the boilers of the second series, then completely different blocks are used there. First of all, they are distinguished by their versatility. Additionally, you can make fine adjustments to the damper of the device. As a result, traction adjusts fairly quickly.

Consumer reviews of Dacon models

Long-burning pyrolysis boilers of this brand are distinguished by their economical fuel consumption. They are also completely environmentally friendly and do not harm human health. Loading chambers in many models are quite voluminous. Due to this, you can bookmark firewood with great comfort. Their efficiency reaches 80%. Of the shortcomings, reviews note only poor contours. In general, they are made from thin sheet metal and temperature are kept weakly.

Exhaust fans are installed in a variety of ways, and they depend on the power of the unit. Ash pans are mounted quite convenient, but in some models they are of small volume. As a result, the owner has to remove the ashes very often. Boilers do well with large pieces of wood. Without electricity, these devices can work, but paired with other heating devices are operated more efficiently. When the fuel in the chamber runs out, the device will turn off automatically. It will be difficult for the consumer to choose a compact model of this brand. Basically, the manufacturer is engaged in the manufacture of powerful units for large rooms.

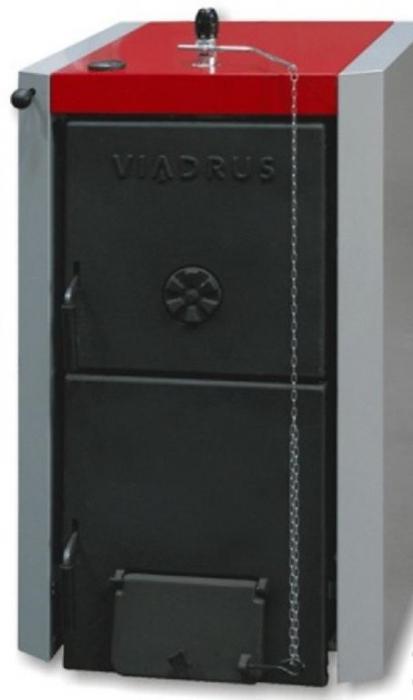

Overview of boilers "Viadrus"

"Viadrus" is famous all over the world for its quality. According to the characteristics, the products of this brand are similar to the Teplodar models. Heat exchangers are made exclusively from refractory steel. The air flow is controlled mechanically. The average power of devices fluctuates around 25 kW. The bunker is designed for a volume of up to 90 kg. The heat transfer efficiency of the device is 90%. Features include interesting models who have hob. All this gives the owner the opportunity to cook various dishes without spending electricity at all.

Fireboxes in all models are of frontal type. Boilers are able to work on chips and chips. On average, the heating area is 120 square meters. m. On one load of fuel, the unit is able to hold out for about 7 hours. As a result, we can say that pyrolysis boilers (solid fuel) for long burning of this brand are most suitable for summer cottages and small cottages.

Pyrolysis boilers with and without a water circuit are highly efficient equipment for high-quality and fast heating of premises. The advanced technologies underlying manufacturing, absolute safety, high heating speed and other advantages make these devices a separate group of modern heating devices that have already managed to occupy a worthy niche in the market, acquire a wide audience of fans and positive reviews.

The essence of pyrolysis

The firewood laid in the boiler chamber gradually burns out and smolders. At the moment of insufficient oxygen, in addition to heat, smoke and a certain amount of combustible gases are formed. Unlike wood fuel, anthracite almost entirely consists of carbon, which allows us to speak about a smaller heating effect and the release of only carbon monoxide. The composition of firewood is dominated by cellulose (carbohydrates) and contains a decent amount of water, so this type of fuel emits a wide variety of substances.

Comparison of the device of boilers

The combustion time of gases is minimal, and soot is practically not formed during the combustion process, which has a positive effect on the efficiency of the heater. To activate the gas evolution process, the boiler should be well heated. Most often, a special design is used for this. Despite the fact that gas-fired boilers are somewhat more expensive than conventional solid fuel models, these costs will more than pay off in the near future.

Device and principle of operation

The design of the boiler includes 2 chambers: the lower one is designed for pyrolysis, and the upper one is for combustion of gases released during the combustion process. Since all processes proceed under the influence of high temperatures, all elements and the boiler body must be made of heat-resistant materials. Most often, manufacturers resort to cast iron because of its super strength, good resistance to corrosion and temperature effects. Often there are also boilers made of steel, which heat up very quickly and also cool down quickly. Such designs provide for the presence of a special ceramic coating that protects the steel from burning through.

pyrolysis boiler

The working principle of the pyrolysis boiler is the process of generating pyrolysis gas from solid wood when temperature regime from 200ºС to 800ºС and lack of oxygen and subsequent afterburning of the evolved gases, which are mixed with secondary air already in the afterburner compartment.

For this:

- solid fuel resources are placed in the loading chamber;

- using the regulator, the combustion mode is selected and set, upon reaching which the boiler performs the functions of a furnace;

- after the combustion chamber is warm enough, the regulator switches to the pyrolysis mode. At this moment, air access is blocked, due to which the wood gradually smolders and the space is filled with a large amount of carbon dioxide;

Pyrolysis boiler with bottom chamber

- gas moves to the second chamber, which is usually located at the top of the boiler, but in some models it may be at the bottom;

- mixing with oxygen, the gaseous substance is burned, while an additional amount of heat is released, which heats the room.

Important! Since long-burning pyrolysis boilers with a domestic water circuit are modern and productive heating appliances, then they provide for the possibility of easy and effective control over the combustion process. In addition, they solve the problem of creating favorable conditions for the formation of the maximum amount of emitted gases and heat.

Fuel

Equally productive solid fuel boilers can operate on any solid fuel - it can be peat, coal (both black and brown), ordinary wood, fuel briquettes. Since all the mentioned raw materials have their own distinctive features and quality, then their complete combustion time is also excellent. For example, the burning time of soft wood is 5 hours, hardwood - 8 hours, and the burning time of coal reaches 10 hours.

Wood is one of the most affordable fuels.

In this regard, the opinion of experts is also curious: they all unanimously assert about high performance boilers that work on hard and dry wood. To achieve maximum performance, good heating of the room and long-term trouble-free operation of the equipment, it is recommended to use dry firewood, the length of which does not exceed 60 cm, and the humidity is 20%.

Important! The color of the pyrolysis gas is almost white, while no side substances should be formed during combustion. However, with excessive high humidity solid fuel the appearance of tar, soot, a sharp decrease in the calorific function of the equipment and even its spontaneous attenuation is not ruled out.

Comparing wood and other solid fuel raw materials, which can only be used for the uninterrupted operation of a pyrolysis boiler, with gas, one can note the availability and environmental friendliness of the former, the high cost, and in some cases the impossibility of building a gas pipeline.

As for solid fuel, there is plenty of it in every Russian region, and for its transportation, only a highway and a capacious transport will be required. For many residents countryside pyrolysis boilers operating on solid fuel resources are a real salvation.

Advantages of pyrolysis boilers

Before purchasing and installing such heating equipment, you should carefully identify and analyze all the pros and cons of a particular model or type of boiler.

The pyrolysis boiler is quite efficient and at the same time easy to operate.

So, a long-burning pyrolysis boiler, compared to other heating devices, has a number of undeniable advantages:

- the fuel consumed is affordable and freely available;

- high efficiency when using firewood and quick heating of the room, regardless of its dimensions;

- high rate of heating of the coolant;

- long work with one loading cycle;

- affordable functionality and simple adjustment of the intensity of combustion;

- ease of maintenance;

- good stability of work and long, maintenance-free operation;

- ease of installation of the pyrolysis boiler, no need for laying and connecting the pipeline;

- heat loss is very small;

- easy cleaning of equipment due to the formation minimum quantity ash in the chamber and chimney during operation;

- the minimum volume of emissions allows not to pollute the environment.

Installed pyrolysis boiler

Pyrolysis boilers for long burning, unfortunately, are not without drawbacks. One of the main drawbacks is the price of the device. Regardless of the manufacturer and design features of pyrolysis boilers, they are all somewhat more expensive than other solid fuel appliances.

In addition, these boilers are single-circuit devices that are not designed to heat domestic water. Another drawback, which was already mentioned earlier, is the sensitivity of the equipment to the moisture content of wood: at high levels of humidity, the efficiency and efficiency of the device may decrease. It is impossible not to note the impressive size of the unit. And finally, the regulation of the intensity of combustion is possible only in manual mode, full automation is not provided.

Factors of efficiency of pyrolysis boilers

The performance of heating equipment, the efficiency and speed of heating the premises, in addition to fuel resources and their humidity, are also influenced by the following factors:

Choose a boiler depending on the characteristics of the room

- room temperature;

- the temperature level to be reached;

- presence (absence), as well as the quality of building insulation;

- specifics of the current heating system.

How to choose the right boiler

If you have the opportunity to buy inexpensively or prepare wood in advance, then you can safely and for a long time without doubting the high productivity of work, buy and install a long-burning pyrolysis boiler at home.

If you are not at all sure of this possibility, then we recommend that you pay attention to the boiler, the furnace of which combines 80% pyrolysis combustion of solid fuel resources and 20% conventional. These devices are considered combined, since they allow you to burn not only traditional firewood, but also wood and coal waste, peat waste, as well as any other fuel mixture, the humidity of which will be less than 50%. Such a combined heating device it is able to burn about 80% of solid fuel in the pyrolysis mode, and the remaining 20% - in the mode of the most ordinary boiler that runs on solid fuel resources.

Pyrolysis boiler device

When buying a boiler, be sure to visually evaluate the volume of the loading chamber. The best option a device will become, the loading capacity of which will be able to fit wood 65 cm long. The coating of the chambers is also of no small importance: the presence of ceramic concrete guarantees the integrity of the compartments at maximum heating, protects the walls from burning through and ensures the necessary combustion of raw materials.

Attention! Check out technical specifications the equipment you like. Special attention pay attention to the indicator of the duration of combustion of fuel resources: the average duration of combustion should not be less than 10 hours.

Pyrolysis boiler operation: video

Pyrolysis boilers for heating: photo

Most pressing question in winter cold - this is heating. And many, whose household is located outside the city, cannot use gas, and sometimes even electric devices due to the lack of backbone networks or their insufficient power.

In this case, the most important choice is solid fuel equipment. And most often, long-burning pyrolysis boilers are used for heating.

Why they? The answer to this question was their design features and operating principle.

What is wood pyrolysis?

In order to appreciate the capabilities of long-burning devices, it is necessary to find out what is the uniqueness of this process. Pyrolysis is the decomposition of wood into gaseous products and dry residue (charcoal).

But this process is possible only without air access and at a sufficiently high temperature. Hardwoods are most often used as fuel for such equipment, although conifers can also be used.

Principle of operation:

Usually, the vessel in which pyrolysis takes place is a retort, which is a closed structure with a low oxygen content inside. It is equipped with a branch pipe necessary for the removal of the resulting gases, which are then condensed and burned.

To more clearly imagine the process of operation of such equipment, consider its design features. the best way to learn all the nuances that long-burning pyrolysis boilers have, is to watch video materials. They show all the main components of the unit and explain their differences from traditional models.

Gas generating heating equipment

The principle of operation of such units is based on the combustion of gas that is released from firewood under the influence of high temperature and with a minimum oxygen content. In this case, the wood is separated into gas and coke, which is almost pure carbon and is the final product of gas generation.

Because of this principle of operation, the equipment is called gas-generating or solid fuel. Today, a long-burning pyrolysis boiler, reviews of which can be found on the net, is becoming more and more in demand. And such popularity was brought to him, first of all, by his unique abilities and high efficiency.

The gas emitted during the operation of pyrolysis boilers is cleaner even in comparison with wood. It is burned in furnaces, where it is converted into condensate and mixed with air coming from the nozzle.

The gas emitted during the operation of pyrolysis boilers is cleaner even in comparison with wood. It is burned in furnaces, where it is converted into condensate and mixed with air coming from the nozzle.

The temperature in this case can reach 700º C. The only nuance in their work is the humidity of the firewood. Different models have their own values, but only with completely dry fuel this boiler has an efficiency of about 85%.

At the start-up stage, pyrolysis boilers operate as usual until a certain temperature is reached, and only after warming up are they transferred to the required mode using special gate valves (valves).

Design features

Solid propellant devices of this type consist of a firebox divided into 2 chambers:

- Downloads

- combustion

In the first, the process of pyrolization of firewood takes place, and in the second, the gases released are burned with minimal heat removal at the same time. Between the fireboxes there is a grate with briquettes. Primary air moves from top to bottom through the layer of wood. This principle of operation, called top blowing, is the main difference between pyrolysis devices and all other models.

Watch the video, start the boiler:

Fireboxes having such a design are characterized by increased aerodynamic resistance and have forced draft. Moreover, it can be performed both with the use of a blower fan and with the help of a smoke exhauster. This option is used for small devices.

Long-burning pyrolysis boilers have a lot of advantages, among them:

- Possibility of using the heat obtained not only from the combustion of firewood, but also from the gas released during this

- Minimal ash formation and total absence of soot

- Higher efficiency than traditional models, so they maintain the required temperature for longer

- The time of work on one tab for many is more than 8 hours

- Minimum content of harmful impurities in exhaust gases

- Power control from 30 to 100%

- The possibility of recycling rubber and polymers without harming the environment

Consumers have already managed to appreciate all these qualities and prefer gas-generating models. This is evidenced not only by the ever-growing demand for pyrolysis boilers of precisely long burning, reviews of which note ease of operation and good economic benefits.

The disadvantages of these devices include their dependence on electricity, big sizes and exactingness to the wood used (firewood must have a certain moisture content).

Main types of fuel

Gas generating equipment can operate on:

However, it is required that their humidity does not exceed 40%. But dry wood is considered the ideal fuel for pyrolysis apparatuses, only in this case the maximum power of the apparatus will be achieved. For example, when burning 1 kg of firewood with a moisture content of 20%, a power of 4 kW is achieved, and if the humidity reaches 50%, then only 2 kW.

Comparing the obtained results, we can conclude that the efficiency of the device directly depends on the moisture content of the fuel. This indicator must be taken into account by those who decide to buy long-burning pyrolysis boilers for heating their own homes. When choosing a model, pay attention to permissible humidity firewood, this will help to avoid errors in further operation.

Why a pyrolysis apparatus?

The duration of the operation of heating equipment depends on many factors:

- room temperature

- type of fuel

- heat-saving properties of the building

- correct system design

And if we compare conventional solid fuel apparatuses and pyrolysis boilers long burning, then there is no doubt that the latter is most effective. After all, in the process of burning firewood in it, you can get such high temperatures that are impossible when using conventional solid fuel equipment.

This feature is associated with the principle of operation of the apparatus, namely, the combustion in it of not only firewood, but also gases released during their combustion. At the same time, the combustion of pyrolysis gas does not require such large volumes of secondary air as when operating a conventional solid fuel boiler.

Does it have any disadvantages?

If you decide to install a long-burning pyrolysis boiler in your house, then in addition to its advantages, you should also learn about the disadvantages. In terms of design and ability to heat a room, it is far superior to traditional models.

If you decide to install a long-burning pyrolysis boiler in your house, then in addition to its advantages, you should also learn about the disadvantages. In terms of design and ability to heat a room, it is far superior to traditional models.

However technical features, which made it possible to extend the time of work on one tab up to 8 hours, led to an increase in the cost of equipment by an average of 2 times. Therefore, the price for modern pyrolysis boilers is quite high. This somewhat restrains the growth in demand for devices of this type.

If you are thinking about which heat source to use in winter period in a house where there is no access to the gas main, you can pay attention to Russian pyrolysis. Even if you have access to the gas supply line, the cost of fuel can be quite high. It is very inconvenient to use coal or firewood, and electricity is expensive.

When to Use a Pyrolysis Boiler

If you have the opportunity to use pressed briquettes or wood as fuel, then as optimal solution there is an installation that uses the principle of pyrolysis combustion. The efficiency of such a device is quite high, however, it may be problematic to purchase an industrial model, since the prices for these units are high today. If you are one of those craftsmen for whom the manufacture of such a design is a simple process, then it is worth understanding this issue in more detail.

What is pyrolysis combustion

If you are interested in a long-burning pyrolysis boiler, then this can be called very justified. It is not very convenient to use firewood as fuel, since under normal conditions they are consumed quickly, and a significant part of the heat is simply not used. This entails the need to load them into the furnace or boiler constantly. Pyrolysis also involves the creation of such conditions under which the fuel is consumed very slowly, giving off a large amount of heat. A similar effect can be achieved when the process is run at low oxygen levels. This makes it possible to obtain combustible gas, coke and ash. The gas in the described installation is mixed with oxygen and burns at high temperatures, releasing a large number of heat. Thus, the principle of operation of the boiler includes two stages. First, with a limited supply of air, wood burns, then the gas-air mixture reacts. Such a two-stage principle of operation uses not only a long-burning pyrolysis boiler, but also wood stoves and solid fuel generators.

If you have a pyrolysis boiler, you will need to properly adjust its operation, which eliminates the possibility of damage to the heating system at home. The high cost of factory units can be called justified, this is due to the fact that when they are created, high-quality material is used that can withstand high temperatures. We are talking about 8 mm alloy steel, heat resistant iron, but this list cannot be called complete. The second factor that affects the high cost is a rather complex control system that ensures efficient operation. In order to achieve the maximum burning effect, it is necessary to take into account the initial moisture content of firewood and the heating temperature, since the process of water evaporation affects the amount of energy released. To control the process, you need to control the amount of air that is supplied to the device. The long-burning pyrolysis boiler has a fan, due to which air is supplied. For its operation, it is mandatory to have access to electricity. The presence of this element turns the device into an electrically dependent unit. Source is used when disabled uninterruptible power supply or similar device.

Design features of the pyrolysis boiler

If you will be manufacturing a long-burning pyrolysis boiler, then you should familiarize yourself with its features. Among the main elements, one can single out a combustion chamber, pipes for draining and supplying water, a fan installation site, air holes, smoke channels as well as regulators. For a private house, it is recommended to use equipment with a power of 40 kW. If this indicator needs to be reduced or increased, then the parameters of the unit should be changed. If it's about small house, then the power can vary from 25 to 30 kW. If you make small units, then you can save not only money, but also time.

Preparation before assembly

The best long-burning pyrolysis boiler is the one that you make yourself. After all, you will know exactly what features it has, which means you can handle repairs if necessary. For the manufacture of such a complex device, it will be necessary to prepare a wide range of materials and tools, including an electric drill, electrodes, the diameter of which is 125 millimeters, 4 mm metal sheets, a set of profiled pipes, a fan, as well as welding machine. In the latter case, it is best to use the model direct current. You will need a grinder with a diameter of 230 millimeters, as well as a set of pipes of different diameters. The master will also have to prepare several strips of steel, each of which must have a different thickness and width.

Long-burning pyrolysis boilers, prices for which can be 40,000 rubles, should be made of sufficiently thick steel; 4 mm sheets should be used for this. But in order to save money, 3 mm steel can be used for the case.

Work technology

In this type of boiler, the feed opening should be slightly higher than in conventional boilers. It is important to install a limiter that allows you to control the amount of air entering the fuel chamber. With it, it will be possible to report briquettes and firewood in a timely manner. For the manufacture of the limiter, you can use a pipe with a diameter of 70 millimeters, its length must exceed the length of the unit body. Homemade long-burning pyrolysis boilers must have a steel disk that is attached to the bottom of the limiter by welding. This disk will form a gap with the walls of the pipe, it should be 40 millimeters. To mount the limiter in the cover of the device, you need to make a hole. As for the fuel inlet, it must have rectangular shape. It is closed with a door, which has a special metal lining, it will ensure a secure fit. Below there should be a hole to remove the ash. The pipe through which the coolant will move inside the boiler must have a bend, which will improve heat transfer. It is possible to regulate the volume of coolant that enters the boiler by means of a valve, it is installed outside.

What to look out for

Household long-burning pyrolysis boilers can be started after manufacture, the absence of carbon monoxide in the combustion products will indicate that the design is functioning correctly and is executed accurately. During operation, you will need to regularly monitor the condition of the seams, cleaning the structure from accumulated soot and ash. Experts advise using pyrolysis boilers with air heating systems, replacing them water heating. The air will be conveyed through the pipes, returning along the floor. Such a system will not freeze when the temperature drops, which can happen when the owners of the house leave. In this case, you will need to drain the coolant.

Conclusion

On sale you can find Atmos long-burning pyrolysis boilers, their cost can be equal to 65,000 rubles. However, you can make such equipment yourself.