Solid fuel water boiler. Features of pyrolysis boilers. Video: presentation of solid fuel boilers of long burning series "Bourgeois-K"

Solid fuel boiler long burning with water circuit for heating country house would be the best option. Such equipment is gaining more and more popularity today. And this is not strange, because not every settlement can connect to the gas pipeline. Often there is simply no gas pipeline outside the city, and you have to look for alternatives heating systems. One alternative is to use electrical equipment, but such air heating in the house will be very expensive. Economical and yet effective solution there will be the use of solid fuels, long-burning boilers have proven themselves especially well. If such devices are also equipped with a water circuit, then you can easily provide comfortable temperature conditions in the house.

The pump pumps deliver the generation pulse from the falling demand front for melting. We move the control valve if it melts or the summer valve runs out. First, we need a valve and a subsequent pump. If we have more outdoor temperature but they are not ideally located, we will use less. We create a time program to control the hot water temperature. In all cases there are four temporary breaks per day. We can create a time program in terms of days such as daily, weekly, domestic and wedding days or user-defined.

When choosing equipment, you need to pay attention to several factors:

- To study the principle of operation of a solid fuel device with a water heating circuit;

- Get to know the possible additional equipment, which can significantly increase the performance of the boiler;

- You should also find out what are the advantages and disadvantages of this heating equipment.

After familiarizing yourself with these three nuances, choosing the best boiler will be much easier. Also, you can finally decide whether a long-burning unit is suitable for you, or it is better to buy an electrical device.

In this timer, the operator enters the value you read from the output variable from the equithermal curve. Thus, many functions can be performed. If it is out of bounds, this change is set to the boundary value. We will activate the regulation to the value if the demand is for meltdown. This function must be disabled when heating from low temperatures, otherwise the algorithm will not work properly.

By setting two or more currents at different temperatures, we observe a sufficient distance from this place for the purpose of misalignment High Quality media. If we make a binding to the heating zone, so as not to close the sleeper closure when the heating zone is closed, and not create such misleading information that someone is closing heat pipe manually, the pump does not turn off the pump, and thus the water pump and pump, and the heated water is heated at this time, even if the heating water does not flow into the heating circuit.

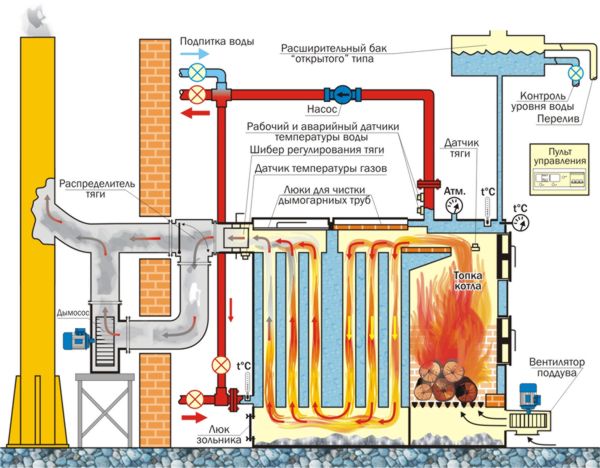

Solid fuel boiler device

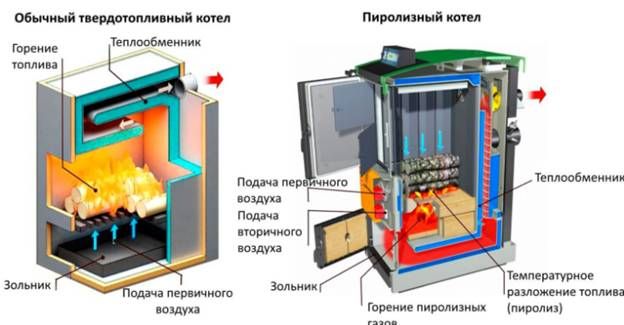

If we compare such a unit with a furnace, then the principle of operation of the equipment is also different. In the oven, thermal energy produced by the combustion of wood or coal and the subsequent transfer of temperature brick walls. In boilers, heat also appears due to the combustion of solid fuel, but the gases do not go outside through the chimney, but remain in the system, where, thanks to a special principle of operation, they remain and are burned in the chamber. This allows you to save fuel and increase the performance of the device.

Comfortable sleepers and thermostats are probably the most helpful for temperature, but they're not the most obvious. For snowy snow, it is more important to follow the installation procedure, since when it is installed, the temperature can change from the actual temperature to the riser. If we place devices in horizontal pipeline, we do not put them above and below the pipeline, since in most cases there is no average temperature of the medium. We mount the instrument strongly, minimally so that it cannot be moved by hand. Some equipment comes with mounting brackets that are not suitable for the application and can therefore be replaced with a high support package.

- We will remove the color from the mosque so as not to interfere with heat transfer.

- Place the heat conductive paste on the mist.

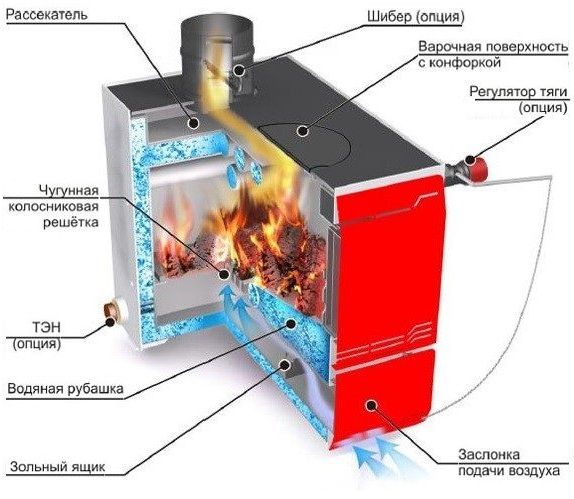

The long-burning boiler consists of the following elements:

- Device case;

- Several combustion chambers;

- Heat exchange element;

- Ash pan;

- Grate.

The design of the unit is really very simple, you can easily assemble such a boiler yourself if you have basic welding skills. Do-it-yourself construction and installation will help save a lot of money. Of course, not everyone feels confident in welding, and factory boilers look prettier and more reliable, so you should also familiarize yourself with the models that are currently popular on the market.

The end of the sleeper must be made on the axis of the pipe, that is, in the middle of the pipeline, and in some cases not touch other sections of the pipe. Remove in this way with a heat-conducting paste to retain the warmth of the heat as much as possible. “The programming of the control system is described in a logical sequence so that it can be applied to various systems". The goal was to create a "helper in your pocket" for designers, programmers and methods of assembly and control.

The solid fuel boiler market has recently come under legislative pressure to improve the efficiency and safety of boilers and to create pollutant emissions. All subsidies currently prepared will be linked to these conditions. Boilers for hot water are prepared for this condition in advance. Let's look at the news that are presented on the designs.

Equipment Features

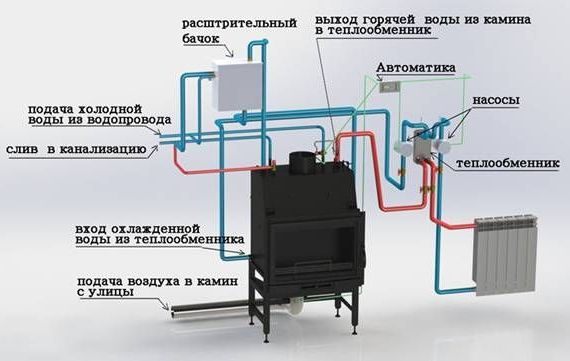

Such a boiler is significantly different from other options for heating equipment. The main and most functional difference is the water circuit of the device. This is what allows the boiler not only to heat the air in the house, but also to ensure uninterrupted supply of hot water in the house.

Immediately it is necessary to say about the price. At solid fuel boiler heating, it is slightly higher than that of standard models, but given the functionality, efficiency of operation and other nuances - the money paid fully pays for itself with comfort.

Boilers of the highest emission class from traditional domestic manufacturers

The manufacturer offers nine model boilers built in the emission class. The boiler unit of the boiler ensures continuous modulation of the boiler over the entire output voltage range from 5.5 to 19 kW. This is the way to achieve high work efficiency. Along with the lambda probe, which optimizes the combustion process, the boiler achieves very low emissions.

Key options include automatic ignition, flue gas removal, automatic exchange switch, lambda probe and turnstile powered pellet drives. These automatic boilers designed for the production of objects, the heat loss of which does not exceed 28 kW. Coppers can work from 7, 2 kW. The boiler uses a completely new retort concept that ensures the correct operating parameters of the entire boiler. Severe is built on the principle of lower filling, and the combustion itself can be compared with combustion in a metal drive.

Another fairly significant advantage of the equipment is that a boiler of this type has small dimensions and at the same time high power. Long-burning devices can be installed not only in small country houses, but even in industrial premises, there will definitely be enough power for heating.

Fuel is supplied from the fuel supply to the retort and rotor. The tag is stored at both ends for better fueling, and the end of the wire under the retort is modified so that the fuel is printed as easily as possible on the circular rotor, where it burns as much as possible. Both round and retort are made of high quality cast iron.

Approximately 20 models for manual and automatic wood combustion are available in the assortment. The boiler allows fueling - a piece of wood or wood pellets - and is offered in several versions - one of which is a regasification boiler without the idea that the pellet can be taken and installed later. Another option is to add an oil burner. The boiler itself is made in the form of a body with three chambers located in the same position. Two chambers are drilled for wood gasification, the smallest chamber is equipped with the necessary burner and ceramics for optimum combustion quality.

Fuel

When choosing heating equipment one of critical factors become the availability of a particular fuel. So, if there is a timber processing plant near your village, then a lot of production waste will probably accumulate there. Wood cuttings, bark, sawdust, all this can turn into excellent fuel. It is the waste that becomes the main source of heat for the enterprise itself and the nearest settlements. Sawdust and tree bark can be pressed into briquettes, which are perfect for long-burning boilers. When the object has a lot of wood chips, bark, and sawdust small sizes, you can start the production of pellets and granules.

The combustion systems are separated from each other by water vapor and thus they do not affect themselves, and thus the boiler achieves high fuel efficiency by heating the fuel individually. The outlet of flue gases into the chimney is marked with one outlet through the neck, thus providing one chimney.

The boiler has a nominal power of 24 kW, which can operate in adjustable power ranges from 7 to 26 kW. The boiler has a built-in fuel feeder for 250 liters of wood pellets and is certified in the emission class. The boiler body has steel structure with cast iron beds. The retort is inserted into the lower part of the boiler body and a ceramic catalyst is placed above it. The shape of the catalyst will lubricate the flue gas back to the burner, which will ensure perfect fuel burnout and flue gas combustion.

Traditional types of fuel are called ordinary firewood, coal and peat briquettes. Each of the materials different temperature combustion, and some boiler manufacturers advise using only one type of fuel for quality work equipment:

Subsequently, the flue gas is fed to back wall boiler body, from where it enters into a tubular exchange with the turbulators and, therefore, by burning the flue gases into the chimney. Power options offered range from 15kW to 42kW rated power. As standard, the boiler is equipped with an anti-air fuel system.

Boilers for burning alternative pellets

It was interesting to compare the systems as manufacturers deal with burning high quality pellets and how they approach building holes. The boilers are designed to burn low-grade wood pellets without any problems, pellets containing bark, mosaic pellets and other soil materials. Generally, vegetable fuels cannot reliably burn fixed artillery or retort structures. The company has specialized for several years in the combustion of pellets and agropal and offers several models in both hot and cold versions.

- Tree of all kinds.

- Any coal.

- Peat briquettes.

True, there are many universal models on the market for which the type of fuel used is not important, materials can be alternated or even mixtures can be made from them. Also, long-burning boilers are divided according to power, combustion principle, autonomy, etc.

The boiler is certified for pellets in emission class 5, for pellets in the class. In predetermined cycles, the engine will ensure that the fuel moves on the shaft and that it is completely destroyed. This hunting system is also designed for fuel that sparks when burned. Fuel automatically ignites electrical system hot air. The air required for fuel is supplied by two fans overpressure. The boiler system of the boiler provides accurate fuel and air supply to the boilers and combustion chambers based on boiler water temperature, flue gas temperature, outdoor temperature and outdoor temperature.

Material

It should be noted that today the market has different variants solid fuel boilers of long burning. There are many differences between them, and it is important to choose really high-quality equipment.

Be sure to pay attention to the properties of the heat exchanger, the type of fuel supply (there are models with manual loading, and there are those where the whole process is automatic). Equally important is the material from which the boiler is made. Today in the production of such equipment are used:

Granulation also in the interior

The asbestos fuel ash is transported to the end of the lift by moving the holes and is directly removed from the bottom of the combustion chamber directly to the outer tank of the boiler from the outside. Furnaces with warm air have a built-in 32 kg tablet that provides unmanned operation for 50 hours. Room stoves, fireplaces and flaps are one of the main design "options", these stoves are offered in several color solutions, including a combination of tile materials.

- Cast iron. Usually a cast-iron body for those models that are designed to heat large industrial premises. The advantages of cast iron are long term services and high strength, there will definitely be no problems with repairs;

- Steel. Compared to cast iron options, such a boiler will cost less;

- Combined variant. In such boilers, manufacturers have tried to provide the unit best performance multiple materials.

The ovens feature high efficiency of 91% and adjustable power from 1.8 to 8.1 kW. The aesthetic advantage is the rear exhaust smoke and vertical panel management. The ovens can automatically regulate the temperature - modulate the fan speed and feed pellets.

Biomass boilers from foreign manufacturers

The boiler has high efficiency 95% at full load and partial power. The controller is configured for a touch screen and interacts with a built-in lambda probe with automatic recognition of fuel quality. Equipped with equidistance control system, automatic sliding rods for ash removal without ash and built-in hydraulic module consisting of two circulation pumps for heating circuit or boiler. Of course, this is automatic ignition, or shift and emission parameters that correspond to the emission class.

One of the most important parameters boiler equipment is the performance (power) of the device. If you save and buy not enough powerful model, then in winter time the boiler will not be able to heat the room. If you install a boiler that is too powerful, the fuel consumption will be excessively large, and this is uneconomical.

The boiler is equipped with a pneumatic blower, which ensures an optimal combustion cycle and a long boiler life. Another feature is the wear of the flue gases around the channels in case of overflow, which takes care of the clean environment around the boiler during fuel filling during operation. The boiler also boasts a special anti-stationary space casing that can be easily replaced in case of damage. All components of the boiler are solid and with an emphasis on a sufficient size of the chamber and ashtray.

The main advantages of this type of boilers

Such solid fuel boilers have really become very popular, and all thanks to the important advantages:

- Economical work. Firewood for the boiler is inexpensive, but at the same time they burn for a very long time and generate heat;

- Affordable price. If we compare the cost of a solid fuel unit, which is equipped with a boiler, and the cost of a model with a water circuit, then the second one will be much cheaper. Also important point is the low price of fuel, because coal, firewood or peat are significantly lower than gas or electricity;

The pellets are filled with it at the bottom, without any disturbance of the flame. During the combustion process, the pellets are gasified and the gases enter the secondary unit from of stainless steel where secondary air is supplied. Basically, it is a modular gas burner that uses wood pellet gas.

These very hot gases then circulate around indoor unit, which leads to tertiary combustion. Hot gases pass through heat exchange and give their energy hot water. Market for solid fuel boilers in recent times is subject to legislative pressure to improve the efficiency and safety of boilers, and to produce lower pollutant emissions. In addition, any grants currently planned will be subject to class 5 compliance. Manufacturers of boilers to this state of preliminary preparation.

- Wide area of use. Long-burning boilers are used as the basis of the heating system different rooms. You can even heat industrial facilities. A wide range of boilers with different characteristics will allow you to choose best model in terms of cost and power;

- Beautiful appearance. Factory options are usually presented in the form of fireplaces, so the equipment will not only perform its direct heating functions, but also improve the interior of the room;

- Offline work. The unit can perform its functions even without being connected to the mains. This is very convenient for suburban villages, where there are often interruptions in the supply of electricity;

- Easy Installation and operation. You can handle the installation even without outside help, this does not require special knowledge or tools. There will also be no problems in operation, just read the instructions once, and you will understand the operation of the unit.

Varieties of long-burning boilers

Interested in which solid fuel boiler to choose for a private house? To answer this question, you must first familiarize yourself with the main types of boilers and their performance characteristics.

Long burning devices

Units of this type are made in such a way that the process of fuel combustion goes from the top to the bottom. Firewood is also loaded from above. When operating this type of boiler, you will have the opportunity to adjust the intensity of combustion, for this you only need to adjust the air supply system. One of the main advantages of a long-burning boiler is that it can work for 24 hours without loading firewood.

The design of such devices is a little complicated, it consists of an air flow heating chamber, a telescopic element and a distributor. There are also models on the market that have an automatic thrust adjuster, but the final price of the product also depends on the presence or absence of such an element.

Pyrolysis units

In boilers of this type, there are two chambers at once, one is used for the combustion of solid fuel, and the second burns gas that is released from wood and, in fact, is created in the first chamber. The combustion temperature becomes higher, and the efficiency increases accordingly, there is less waste, and pyrolysis boilers considered even more economical. But there is one caveat, to use such a boiler, you need fuel with a moisture content of about 20%.

Universal Devices

These devices are not in vain called universal, because absolutely any type of solid fuel can be used for their operation, and when you change the burner, you can even use diesel fuel or natural gas. Such equipment will be practically indispensable at a time when the house is not yet connected to the gas supply network and to electricity.

But it is worth saying that such boilers have many disadvantages, they have a rather high price, it is difficult to connect such equipment. When using solid fuel economical universal boilers you can’t name it either, they really work effectively only on liquid fuel. But when firewood or coal is used, then universal devices significantly lose in efficiency to pyrolysis stakes. It is also worth noting that all boilers have a security system that prevents the structure from igniting or stopping work.

The main characteristics of the pyrolysis boiler

The two chambers of such a boiler are separated only by a grate, on which solid fuel. Initially, air flows through these chambers from the bottom up. It is the possibility of two types of blast that distinguishes the pyrolysis boiler from the usual version. This whole system works with the help of forced draft, which is created by a smoke exhauster.

How to use the boiler is very simple:

- First you need to lay out solid fuel on the grate;

- After ignition of the material, it is necessary to close the door, at this stage the smoke exhauster starts its work;

- A high temperature is created inside the chamber, at which wood gas and other volatile elements are released;

- All these gases are sent to the second chamber;

- There they mix with secondary air and burn. In this process, thermal energy is released, which again goes to the first chamber.

In this way, it is possible to constantly maintain high temperature, which appears during the pyrolysis process. Therefore, the boiler is called pyrolysis. In this case, heat can be used to heat any coolant.

Pros and cons of pyrolysis devices

In order to accurately determine the type of boiler used, it is necessary to pay attention to the positive and negative sides pyrolysis models. Among the advantages are the following characteristics:

- The dual air supply system, which is in such a device, increases the long-term burnout of one batch of firewood up to 12 hours. This is very important, because in traditional models, the “refueling” of the boiler with firewood must be carried out every 3-4 hours. Therefore, in traditional boilers and fuel consumption is greater.

- Complete combustion of firewood. When the fuel is completely burned in the boiler structure, much less ash remains after heating. Caring for such a design is much easier, because it is cleaner than traditional models.

- In such boilers, two-stage combustion operates, which reduces the amount of air, and provides more efficient work equipment.

- Two fireboxes will also help you control the combustion process and make changes to it. This function allows you to automate the equipment, and it will perform its functions as well as gas boilers. In a conventional wood-fired boiler, this will not work.

- Even large logs can be used as fuel. Therefore, you do not need to spend a lot of effort on chopping wood.

All these characteristics allow us to conclude that long-burning pyrolysis boilers with a water circuit are more functional and more economical than other solid fuel-operated equipment.

To be completely fair, it is necessary to name the disadvantages of such equipment:

- Pyrolysis models heating devices with a water circuit cost much more than conventional boilers;

- Such devices will not be able to perform their functions without a smoke exhauster, so energy dependence is also a disadvantage. In settlements where power outages constantly occur, it makes no sense to install pyrolysis boilers, because without light the heating system will not work;

- At the time of buying Special attention you need to pay attention to the reputation of the manufacturer, it will not be superfluous to read the reviews about the devices. It often happens that only characteristics are declared in the passport data, but in fact the operation of the boiler does not correspond to them;

- When such equipment is turned on at 50% power, tar will appear, which will clog the communications of the gas ducts;

- In order for such equipment to work as efficiently as possible, it is necessary to mix the heated water with the liquid that is sent back to the unit design. The fact is that when the temperature of the return liquid is less than 60 degrees, condensation will appear, and even corrosion may occur.

Installation

First of all, you need to prepare a base for the boiler that will be safe, reliable and durable. In most cases, a reinforced concrete foundation is used, other options are also possible, but on the surface of the base you should definitely put steel sheet which is not afraid of high temperatures and fire. Also, experts advise using a level during the installation process so that the foundation under the boiler is even.

During installation, the following requirements must be observed:

- Do high-quality ventilation;

- Inside the room where the heating equipment is installed, the air temperature should be at least 10 degrees;

- Be sure to build a chimney;

- Make a separate exit to the outside;

- A certain distance must be observed from the walls to the long-burning boiler. All requirements for choosing the installation location can be found in the relevant standards.

It is worth considering that all of the above requirements are not only recommendations for installing the boiler, but also rules fire safety. It is better to contact a specialist during installation, who will do everything in accordance with existing norms and requirements.

Equipment selection

Of course, the design of the boiler is very important, because it will depend on general interior premises. But experts advise, first of all, to pay attention to performance characteristics devices:

- Power. We have already said that choosing the right boiler for power is very important for efficiency and savings. In this case, it is necessary to calculate the heat loss. You can use the traditional formula (1 kW per 10 "squares" of the house), but it will only be relevant for well-insulated houses, in other situations there will be large errors. A professional design of the premises and materials will help you to calculate everything correctly and choose a good boiler. One of the main factors of heat loss are doors and windows. All these calculations can be done on your own, but to get accurate results it is better to call specialists.

- Boiler body materials. Models that are made of cast iron weigh quite a lot, hold heat well, but will be fragile to mechanical damage. Fluctuations in coolant temperature can also harm cast iron structures. Steel boilers are much lighter, look nice, don't take up much space and are easy to install. But there are also disadvantages, only firewood can be used in fully steel units, because when burning coal or briquettes, the temperature will be much higher, and the material does not tolerate this well. The "golden mean" are combined models in which the body is made of steel, and cast iron is used as the heat exchanger material.

- Control option. There are boilers that are able to work with little or no help from people. Even the loading of firewood is done automatically, after a certain time. But all this has a direct impact on the price of the device. Simpler and cheaper models are controlled manually, on a special panel you can adjust traction, pressure supply, fuel consumption, etc.

Popular models and prices

- Stropuva S40. This boiler is produced by a Lithuanian company, and it is assembled at Russian enterprises. S40 is quite large, so when buying, you need to take into account the dimensions of the room. Appearance the boiler is beautiful, so it will not spoil the interior of the room. On one load of combustible materials, the unit will work up to 70 hours, which is one of the best indicators among competitors. The efficiency is about 95%, so the operation of the boiler will be efficient and economical. Buying Lithuanian heating equipment will cost you 110,000 rubles.

- Buderus Logano. This model comes from the Czech Republic and has been popular among users for many years. The boiler is universal, so both liquid and solid fuels can be used. The design is equipped with a large heat exchanger. There is also a pump in the boiler, which ensures efficient operation. This equipment will heat a house of several floors without any problems. The cost of Buderus Logano starts at 41,000 rubles, and it depends on the power of a particular option.

- Prometheus. Here you can be proud of domestic manufacturer, because "Prometheus" is produced by a company from Novosibirsk. There are options with different power, ranging from 10 to 45 kW. This will allow you to choose the best option taking into account the area of \u200b\u200bthe room and heat loss. The boiler works on wood and coal; in case of overheating, it is possible to reduce combustible fuel. A 16 kW model will cost you 34,000 rubles.

- KChM. The very name of the category "Omnivores" suggests that they can run on different fuels. Not only firewood is used for heating, because the design has gas-burners and even nozzles for diesel fuel. The model will be very profitable if you have built a house recently and have not yet decided on the view heating systems, or when gas pipelines are planned in the near future. A 15 kW boiler costs about 33,000 rubles.

How to choose a solid fuel boiler for long burning on wood? Price, user reviews and main features will help you buy the right model.

Not many owners of private houses are lucky with the laying of gas mains. Heating, however, is required in any region of Russia, given climatic conditions. Therefore, the prototypes of Russian stoves - solid fuel boilers new generation, remain at the peak of popularity among the owners of suburban real estate. There are different types, each has advantages and disadvantages. We will help you navigate the variety of models.

The principle of operation of a solid fuel boiler for long burning

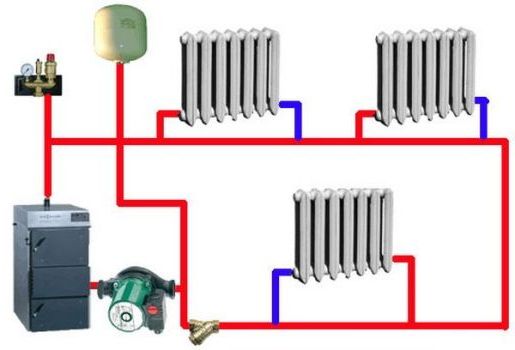

As a rule, any unit is an installation with several combustion chambers. Water jacket for heating the second circuit with the medium circulating through the piping or required for own needs - also applies to the configuration. Modifications can be different, installations are compact or overall.

The principle of operation is simple: burning in one chamber, the fuel emits combustible gases, which in simple ovens fly out into the common chimney. In the same boilers, the gas mass is decomposed, mixed with air and then burned in another chamber.

The benefit is obvious - heat calories are fully used, therefore, in economic terms, a solid fuel boiler for long burning is preferable to others.

Calculation of the thermal output of a boiler with a water circuit

Before purchasing any option, it is important to calculate the heat loss of the house, otherwise the unit will be low-power, unable to provide the proper temperature for the house. Or, conversely, the operation will become too expensive and useless due to a large number consumed fuel.

Calculations are carried out in several ways:

- A popular method - 1 kW of power is required per 10 square meters. However, such a calculation does not give the accuracy of the result, since it does not take into account the building materials of the house, insulation, the size and quality of windows and doors. Applying this formula to calculate the power of the unit, you can make a mistake at times.

- Online calculator. An even more inaccurate result, although easy in the process: it remains to enter the data in the appropriate columns and click the result button. If the owners like this method, they should choose a calculator with scrupulous data - the thickness of the wall, ceilings, materials, parameters of technological openings and other significant factors.

- Using formulas. Based on them, finding heat loss for a particular house is not easy and takes a long time. However, the result will be closer to reality than all those described. If there is no information about all the nuances of materials, you should contact heating professionals.

It is important to consider that solid fuel boilers with a water circuit are purchased with more power, since the use of the resource is costly and the heat transfer of the unit is reduced. 20% is added to the resulting heat loss figure. This is enough for the required power, coupled with a water circuit.

Types of solid fuel boilers for long burning

When the required calculations are made, it is easier to choose a unit for heating a private house. Now they pay attention to other parameters, since the power is already known. The next aspect that we will consider is the types of boilers.

Classification by type of fuel:

coal boilers

These boilers, as a rule, are cast iron, since the combustion temperature of mountain raw materials is many times higher than firewood - metal walls will simply burn out. For better heat dissipation and long-term preservation temperature, the unit is faced with brick, thus turning the boiler into a stove or fireplace.

A coal-fired solid fuel boiler has disadvantages: big weight- in a private house, it is necessary to arrange a separate site with mandatory concreting from the foundation itself and an environment of non-combustible materials.

Permanent soot - you can’t get rid of it, even if the owners are pathologically clean. It is easier to install the boiler in a separate room. A place is required for storing coal, and given that at least 9 tons are required for a cold winter, the hangar must be extensive. And you will have to stock up on fuel in advance if the entrance to the bunker is problematic in winter.

Advantages: coal is a common fuel in many regions of the country, it is affordable and it is not a problem to get it. The boiler is "omnivorous" - not only coal is loaded into it, but also firewood, various garbage, briquettes, waste. Coal boiler is always comfortable temperature in the house.

Pellet boilers

The concept is already familiar to many users of solid fuel units. Pellets are used. They are made from peat, wood and agricultural waste. Appropriate and price. Fuel is classified into categories as premium - white and standard - dark. There is also a species used only for industrial production.

Advantages of pellets: hypoallergenic - the fuel is made from an environmentally friendly product. Low ash content - the boiler is cleaned no more than once a month. High efficiency– up to 86% due to complete combustion. Ease of use - fuel loading occurs no more than once every 3-4 days or even a week. Pellets are safe as they do not contain flammable dust or explosives.

The only drawback is that the storage place must be dry, otherwise damp pellets will not have any effect - they will need to be dried. In addition, the raw material will rot.

Advantages of pellet boilers: they are compact, can be installed in any comfortable spot not against the rules. Boilers are made of metal, lightweight, mobile. Because cleaning is rare, boilers are located even in residential premises without fear for cleanliness. Thick walls will not allow the owners to get burned, despite the high temperature inside the chamber.

Conclusion- a solid fuel boiler is selected according to the available fuel and the financial ability to replenish it in the future. The expenses include the requirement for a separate room - for some units and houses with a large area, this is necessary.

Classification of boilers according to the material of manufacture

There is no wisdom - steel and cast iron are used for the manufacture of units.

- The first option is suitable only for wood fuel, since the specific heat of combustion is much less than coal or peat.

- The second one is suitable for everything, however, it has disadvantages: it is fragile under mechanical stress, sensitive to temperature changes - the supply tank with cold carrier should be installed correctly. A steel boiler has an advantage over a cast iron one - it is not so heavy. It is moved as needed. But the service life in comparison with alloyed (40 years) is short.

Hence the conclusion: cast iron boilers are good for their durability, but installation must be left in the hands of professionals. Otherwise, the service life will decrease significantly if there is no knowledge about the installation. Steel ones are good for summer cottages with seasonal visits, but such units require special care, as they are able to corrode due to long downtime.

Pyrolysis boilers working principle

Long-burning wood-fired boilers designed to use off-gases for an additional process. Actually, pyrolysis is a process used in boilers with any type of fuel, not only for firewood. For example, the combustion of coal pyrolysis boiler increases in efficiency up to 80%. Flammable liquid is also used.

Many options for solid fuel boilers by type of pyrolysis contain additional functions, designed to accept a different type of fuel - that is, combined units. This is advantageous if, at the height of the season, conventional fuel has come to an end.

Advantages of pyrolysis boilers

High efficiency of any fuel - firewood burns almost without residue, and cleaning the boiler will not come soon. Fuel loading - 1 time per day, overall require this 1 time in a few days. The installations are compact, but wiring is required for the second circuit and then the boiler is placed in a separate room. The service life is 15–20 years.

Disadvantages of pyrolysis boilers

Price and dependence on electricity. In comparison with other furnaces and boilers, the cost of the pyrolysis unit is high - 1.5–2 times. But the advantages pay for this minus quickly - the owners will notice this in fuel economy. As for the cost of electricity - the boiler works in tandem with a blower fan, the costs are inevitable, but not critical.

Of course, there is a dependence in the event of an unscheduled power outage, but the unit is equipped with automation, which will not cause smoke.

If it is wrong to choose the power of the pyrolysis boiler for a particular house and heat it by half the parameter, then the chimney pipes will become clogged with tar - a product from incomplete combustion of fuel. Therefore, pyrolysis boilers are suitable for houses with permanent residence and an area of at least 100 square meters.

Proper installation of solid fuel boilers for long burning

There are standards for the installation of solid fuel boilers. Some provisions require strict adherence.

- The place for installation of the unit must be free to move, with an area of at least 7 square meters. If a a separate room is not provided, then a separate area is allocated for the boiler with a sufficient distance from the walls of the house, which should be external, not adjacent to the internal ones.

- The floor is covered with non-combustible materials - metal, asbestos slabs, bricks. The continuation of the foundation will serve as an ideal pedestal. But this, perhaps, only at the beginning of the construction of the house.

- Except natural ventilation, a supply must be present. Chimneys are designed by specialists with strict observance of the cross sections of the channels. The ventilation problem is dealt with before buying a solid fuel unit. Pyrolysis requires special control, given the presence of a blower fan.

- The place where the boiler is installed must not contain or be used for storage of fuel, fuels and lubricants and other flammable materials.

How to choose a solid fuel boiler for home heating

What else to look for when choosing a unit for use? There are other features that are not directly related to the principle of operation or the design of the boiler.

- Manufacturer. Do not chase European standards. Such units are expensive, but absolutely similar to the Russian assembly. Why pay more? Our potbelly stove is good in all respects.

- Power circulation pump . For two-storey houses device is necessary because natural circulation will not lift the media above the water column mark.

- Presence of a boiler system. Even if the family is standard - mother, father, child - this requires large amounts of water for domestic needs. The capacity of boilers rarely exceeds 5 liters per minute, therefore, storage system necessary.

- Automatic protection and dispensers. They allow you to make fuel consumption optimal and turn off the unit in case of an emergency. Don't skimp on your own safety.

So, the choice is up to the owner. Applying the described nuances to a specific model, it is easy to choose a solid fuel boiler with a water circuit for a particular house. Making the acquisition rational is the task of prudent owners.

Solid fuel boilers for long burning with a water circuit video