Long-burning wood-burning boilers. Features of the selection and operation of long-burning boilers. General features of long-burning units

Boilers long burning wood burning are used today for heating private houses and represent improved solutions to previously used wood stoves. In some cases, they represent an excellent alternative to electric and gas heating boilers. However, if you still don’t know whether it’s worth acquiring such equipment, you should take a closer look at it. distinctive features, pros and cons, which will be discussed below.

The main advantages of wood boilers

Modern design and perfect thermal insulation of the boiler saves fuel and operator time. The scalability feature saves energy costs and, in combination with a storage tank, keeps the chiller economically and reliably cooled in the event of a power failure.

Very long service life - 5 years warranty on the boiler body

We have made the most of our many years of experience and have developed a boiler that has original design high quality materials. Using a double wall storage chamber, the boiler parts are made of of stainless steel or a special ceramic microstrip, we have significantly increased the service life.

In addition, there are a huge variety of boilers on sale that could save on heating costs. While others, on the contrary, can cause gaps in family budget, which is why you should take seriously the choice of boiler model for heating. For example, a number of models require adding fuel every 4 hours, while others do not require replenishing firewood during the week.

High efficiency across the power range

The boiler efficiency is more than 90%. You will appreciate this feature, especially if you do not need the boiler's rated output - most heating season. Thanks to modern design combustion chamber and air supply fuel burns evenly. Combustion is good during the combustion cycle of combustible fuel with a balanced boiler output. Proof high efficiency is extremely low temperature flue gases.

When designing the boiler, we thought about the whole family. Simple and intuitive control will soon be available to every member. The application of a horizontal infill door can handle even a smaller figure. Excellent handling and automatic system stator leads to the fact that the amount of heating time per season is several times less than for conventional boilers. Thanks to the long burning time, an average of 2-3 times a day is sufficient without compromising the efficiency and quality of combustion. The design of the boiler makes it easy to clean and remove ash.

The main advantages of wood boilers

Long-burning wood-burning boilers have many positive features; they can be used for heating buildings that are located away from gas mains. If we consider such equipment more carefully, we can highlight some advantages, among them:

- low cost;

- independence from electricity;

- simple installation diagram;

- environmental friendliness.

Low cost, however, is characteristic only of those boilers that are standard units and are not equipped with any ultra-modern functions. These devices are completely independent of electricity. There may be no light supplied to the house, while the equipment will properly cope with its tasks. Long-burning wood-burning boilers are also chosen by consumers for the reason that they are easy to install. They are easy to maintain and repair, which allows for additional savings during operation.

Fuel: piece of wood, wood briquettes, chips and sawdust

The built-in exhaust fan provides excellent flue gases even when the filling door is fully open. The boiler can burn fuel various sizes, including shavings, shavings and sawdust. These fuels can be burned as efficiently as lumber.

Intelligent electronic control controls the required air supply to the combustion chamber and maintains the so-called stack layer in the boiler. Thanks to this technology, the boiler can withstand automatic operation and without use for up to 15 hours. When you get home from work or after arriving from a day trip, you don't need to shoot again, but it's enough to put it on.

Why else is it worth choosing a solid fuel boiler?

It is also important to pay attention to environmental friendliness, because wood is used as fuel, which is natural material. Combustion is not accompanied by the release of external environment toxic compounds that could harm the human body. The only danger is the carbon dioxide produced when wood burns. However, it can only be poisoned if the user ignores the manufacturer’s recommendations for following safety rules.

Possibility of operation in case of power failure

The boiler can only operate using a chimney exhaust. The invaluable advantage of the 35cm length is that it is easier to manoeuvre. The application is so simple, for example for women. An additional undeniable advantage is faster fuel drying. A freshly cut tree 35 cm long will reach the required dryness even after one year of drying, without need. The advantage is also better storage and associated with even lower spatial storage requirements.

They are designed for burning wood according to the principle of gasification of a generator using exhaust fan, which sucks flue gas from the boiler or by means of a pusher fan, which evaporates combustion air into the boiler. The boiler body is made in the form of a welding machine from high-quality steel sheets thickness from 8 to 3 mm. It consists of a fuel hopper, which is equipped with a gasifier at the bottom with a longitudinal hole for the passage of flue gases and gases. In the lower room below, ceramic fittings are provided for perfect combustion of all combustible substances with high efficiency in environmentally friendly combustion.

This indicates that boiler equipment should be operated with the utmost care. If you are interested in long-burning wood-burning boilers, then you should pay attention to another advantage, which is expressed in the possibility of using various combustible materials such as solid household waste as fuel.

At the rear of the boiler body there is a vertical chimney located at the top with a valve. The upper part of the chimney is equipped with an exhaust connection for the chimney. Reverse combustion, preheated combustion air and a ceramic combustion chamber ensure almost perfect combustion with minimal harmful exhalation.

All boilers are supplied in the basic version with a cooling circuit to prevent overheating. We recommend installing boilers with fuel storage tanks to reduce fuel consumption and increase heating comfort. It is necessary to pay attention to the setting of the power regulator, since the regulator, in addition to regulating power, performs another important function, which protects the boiler from overheating. The boiler is also equipped with a control thermostat located on the boiler panel, which controls the fan according to the set outlet temperature.

Main disadvantages

When consumers consider the equipment described in the article, they note that it also has certain disadvantages, which are expressed in:

- impressive mass;

- the need to control work;

- uneven heating of the coolant;

- the need to prepare firewood;

- fairly high fuel consumption.

A number of consumers refuse to purchase such installations for the reason that, made of cast iron and steel, they are characterized by a rather impressive weight. In addition, their work requires control. The boiler should not be left unattended for long periods of time. Every 4 hours you will need to add firewood.

Boilers operate at a reduced power output of up to 70% of rated power, even without a fan. The panel consists of: main switch, safety thermostat, thermometer, control thermostat and flue gas thermostat. Electromechanical control is optimal solution for boiler operation in a simple way. The standard panel design is the basic design for all boilers produced.

Boilers with water circuit

This control can also control the boiler itself via a fan with many other functions. Drain evacuation at controlled speeds ensures optimal combustion and evacuation of flue gases, preventing smoke leakage even during use.

Some consumers are also put off by the uneven heating of the coolant, as well as the impressive fuel consumption, which sometimes does not allow achieving the desired effect, because wood emits a rather small amount of thermal energy during combustion. And the preparation of firewood is a rather lengthy and labor-intensive process.

New concept overhead line automatically adjusts preheating air and primary and secondary air intakes using one control element. Thanks to a special air duct for preheating the fuel, it is possible to close the discharge chamber very soon after the boiler has been welded. Even wood heating can be really convenient.

Wooden boiler with many advantages

Optimal efficiency is also maintained thanks to special cleaning brushes in the heat exchanger.

Large storage area for half a meter

- Suction fan with variable speed for the most convenient operation.

- Convenient fastening Long time combustion Long interpolation intervals.

For reference

But if the house has small area, then storage becomes a real problem, because fuel needs to be stored somewhere, and sometimes a special room needs to be allocated for this. In order to keep the firewood dry all the time, it must be stored under a special shed or in the house, where it takes up quite a lot of space.

Principles of heating organization

Adjustable air supply for heating Optimal combustion process. . As a result, the exact amount of air required to achieve optimal combustion conditions is supplied to each combustion chamber. Thanks to the adjustable heating air supply, it is also possible to close the storage compartment door immediately after igniting the fuel.

High temperature chamotte combustion chamber

It is impossible to melt wood more comfortably. Low emissions Easy to clean Long term services. . The combustion chamber combustion chamber ensures low emissions. The new combustion chamber geometry makes cleaning much easier. Replaceable fireclay lining panels facilitate long-term Maintenance and increase the overall service life of the boiler.

Description of pyrolysis boilers

Perhaps you may be interested in a long-burning wood-burning pyrolysis boiler. This equipment belongs to the family of solid fuel boilers, but has one difference, which is that combustible components are removed from the fuel at the first stage. Combustion is carried out in two stages, first, gas is extracted under high temperature conditions, while conditions are characterized by low oxygen content. At the second stage, a mixture of air and heated gases is burned.

Air cooled storage door and cleaning door

Maximum user comfort Low heat loss High efficiency. . Thanks to the new air flow concept, air is drawn in through the oven door and combustion chamber. The air flow promotes combustion and acts as a boiler cooling function for safer and more comfortable heating. The entire system effectively prevents heat loss and increases the efficiency of the boiler and the entire heating system.

Exhaust fan with speed control

Maximum comfort during operation Reliable ignition of the boiler Continuous optimization of combustion. By regulating the speed and, therefore, the intensity of draft, the boiler creates optimal conditions for efficient combustion when heated.

Heat exchanger pipes with turbulators

Better heat transfer High efficiency Easy to clean. . A special lining in the heat exchanger channel regulates the flow of hot flue gases, ensuring more efficient heat transfer and a particularly high degree of efficiency.Such a long-burning solid fuel boiler with wood has a metal body, inside of which there are two chambers, one of them is the combustion chamber, while the other is the loading chamber. To protect against exposure high temperatures the walls of the chambers are lined with fireclay bricks or other material that is heat resistant. It can be made on a concrete basis.

Turbulators also have a secondary function - they can be used as a brush to clean heat exchangers. This is important to maintain high boiler efficiency; sedimentation of dirt would otherwise prevent efficient heat transfer.

- Ease of handling.

- Smokeless application.

- Clean environment in the boiler room.

The main advantages of pyrolysis boilers

If you still don’t know whether it’s worth becoming the owner of a pyrolysis boiler, then you should consider its main pros and cons, among the first to highlight:

- burning duration;

- almost complete combustion of fuel;

- possibility of using large firewood for work.

If we consider these advantages in more detail, we can note that the described boilers are capable of operating on one batch of fuel for approximately 12 hours. If you use coal, then under certain conditions this period becomes even longer. A long-burning wood-burning boiler is capable of completely burning fuel, which means that the equipment uses most of the energy potential firewood This minimizes waste and eliminates the need for frequent cleaning. And the labor intensity of work when loading fuel will be reduced, because most of the options for the equipment described allow us to limit ourselves to loading uncleaved fuel.

The result is a more pleasant use of the boiler and a clean, smoke-free boiler room. Precise combustion control with standard lambdasson control.

- Large, well-organized control unit with viewing angle adjustment.

- Heating control from the living room.

The main disadvantages of pyrolysis boilers

In order to do right choice, you should also pay attention to the factors that sometimes stop consumers from buying pyrolysis boilers. These installations are much more expensive than their traditional solid fuel counterparts. If you familiarize yourself with the assortment of the market, you can understand that sometimes the difference in cost reaches a limit of 50 to 100%. In addition, long-burning wood-burning boilers for home use forced air injection systems. This suggests that the devices are volatile.

The bus system allows you to place controls where you need them. They can be either on the boiler or in the tank, in the living room, in the bedroom or in a neighboring house or apartment. The system can be connected to other power sources such as solar panels. The control system connection also has minimum requirements for the availability of power lines over the largest supported range.

Heating control is conveniently done from the living room. Find out everything easily important values and information about the condition of the boiler, and use the buttons to make the necessary adjustments at any time. 4. 3-inch color display shows the most important functions and status of the boiler. Depending on the lighting conditions, the touch control unit automatically adjusts the intensity of the display backlight.

The units waste electricity, interruptions of which can lead to big problems. As practice shows, the efficiency of such devices largely depends on the condition of the firewood. If they are wet, the boiler may simply not start. Manufacturers even give recommendations on this parameter. The moisture content of firewood should not exceed 25%, which can sometimes be very difficult to achieve.

Making your own boiler

If, after familiarizing yourself with all the pros and cons of long-burning boilers, you decide to make one of these models yourself, then you should become more familiar with the technology of the work. The equipment can be made of a thick-walled pipe with a diameter of 300 mm, or 4 mm sheet steel. As optimal option a 6 mm sheet will come out. To carry out the work, you will also need a cylindrical container of the required size.

The simplest design is the one made from a barrel or gas cylinder. In order to ensure directional combustion of firewood, a vertical firebox is used. Primary air will be supplied by vertical pipe to the combustion mirror. A telescopic or static structure will need to be installed in the upper wall of the boiler. A rod will run through the center of the cylindrical firebox. A gap must be made between the supply pipe and the collar, which is formed by welding the side; it will ensure the stroke of the rod and guarantee minimal air leakage into the chamber for afterburning wood gases.

If you decide to make a long-burning wood-burning boiler with your own hands, it should include a damper lid that will be located at the top of the pipe. With its help you can regulate the air intake. The disk with blades should be strengthened from below. The blades will cut the air flow in the combustion area. Taking into account the heat capacity, it will be possible to select the material for distribution. The diameter of the disk should be smaller compared to the size of the firebox.

Dimensions of a homemade boiler

Homemade long-burning wood-burning boilers should have the following dimensions:

- boiler height ranging from 3 to 5 diameters;

- the optimal case size is from 300 to 800 mm;

- wall thickness - 4 to 6 mm.

It is also important to take into account the thickness of the disk; this parameter will be inversely proportional to the diameter. The diameter of the disk will be 10% less than the cross section of the chamber. To burn pyrolysis gases, a turbulent flow will be used, which is formed by curved blades. If you are interested in long-burning wood-burning boilers for your home, then you can make one of these models yourself.

When carrying out work, it is important to take into account that a pipe will be responsible for the air supply, the diameter of which will be a coefficient of 0.55 of the cross-sectional area of the exhaust pipe of the chimney. A gap should be left between the collar and the pipe, which should not be more than 2.5 mm. A pipe will be used for air intake, the height of which rises above the collar by 150 mm.

Independent addition of the boiler with a water jacket

A long-burning wood-burning boiler with a water circuit will be even more effective way heating. To connect to the water pipes of the equipment, it is necessary to install shut-off valves. Ball Valves. A cleaning filter must be installed on the pipe through which the cooled water will return. This will protect the heat exchanger from contamination. The same filter is installed on the cold water supply pipe. Shut-off ball valves will be located on both sides of the filters. This will make them easier to clean.

Long-burning wood heating boilers must be installed together with chemical water mixers, which are located in the piping. This will reduce the hardness of the coolant and eliminate the formation of scale in the heat exchanger.

Advantages of a pellet boiler

Long-burning wood-burning boilers (24 hours is not the maximum time without adding fuel) are equipment that allows you to avoid loading resources for a long time. An example is a pellet boiler, which sometimes has a design that allows you to load fuel once every few weeks.

The devices require a container on the side where the pellets are placed. The volume of this tank allows long work boiler without human intervention. The volume of the compartment may vary. Using a special mechanism, fuel is supplied from the bunker to the boiler, which also uses electrical energy during operation.

Pellet boilers are most often chosen by consumers because of their high efficiency, which reaches 95%. In addition, this equipment ensures almost complete combustion of fuel, as is the case with the boilers described above. This indicates that cleaning can be done once a month.

Disadvantages of pellet boilers

Pellet boilers sometimes lose to other varieties heating equipment, because they have a high cost, and also depend on electric current. This equipment uses exclusively low-ash and whole pellets, which can sometimes be quite difficult to find on sale.

Conclusion

Solid fuel boilers act as an excellent way to power the home autonomous heating. With the help of such installations you can save a lot on energy resources. Some craftsmen are so confident that solid fuel boilers are the best among other types of heating equipment, that they even try to make such equipment themselves, because if you buy it in a store, it can be quite expensive.

IN last years Heating costs are increasing more and more. However, in a country where in most regions the cold season is 7-8 months a year, you cannot do without it. Apartment owners are forced to come to terms with huge utility bills. But owners of individual houses have long been looking for an alternative central heating and standard gas boilers. And of course they find a long-burning wood-fired boiler ( wood boilers).

Rice. 1Advantages and disadvantages of heating boilers

Compared to all other types of fuel-burning equipment, wood-burning equipment equipped with long-term combustion has the following heating advantages:

- High level performance and heat dissipation. Boilers can heat large areas and multi-room spaces. One can heat a house or cottage with an area of up to 200 sq.m.

- Public availability of fuel - firewood. Pellets, sawdust, coal and peat briquettes, as well as any combinations thereof, can be used as fuel.

- Economical. With the same amount of heat supplied, the fuel costs of a wood-burning boiler are significantly lower than those of a gas boiler.

- Autonomy of work. Wood-burning boilers do not require connection to an electrical network, gas pipeline or other communications, which allows them to be used in any premises and buildings.

- Long-burning wood burning equipment are highly reliable and durable, since they are made of steel or cast iron. Average term equipment service life - 15 years.

- The design of the boiler is extremely simple, it does not require maintenance special knowledge and skills, thanks to which many competent craftsmen have the opportunity to make it with their own hands. And homemade heating device At the same time, it will not be inferior in power and performance to the branded one.

However, like anything complex equipment have their drawbacks, the main one of which is the need to install a chimney with good draft and separate room in the basement or extension of the house. Also, many long-burning models are very sensitive to the quality of the fuel, that is, the firewood you put into it yourself must be dry.

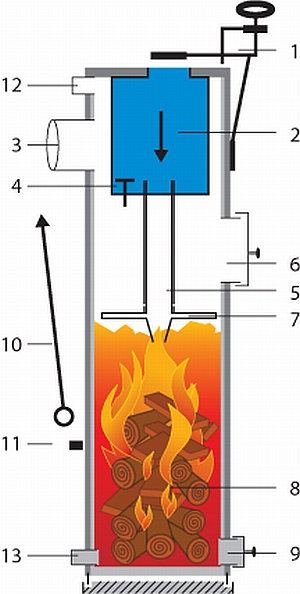

Wood boiler design

The design of a long-burning wood heating boiler is extremely simple and at first glance is not much different from a traditional stove.

Its main elements are:

- A firebox that performs the functions of a heat exchanger, which includes a door, a hole for the chimney, an ash pan (a container for collecting ash), and a blower. This is where fuel combustion occurs. Its size depends on the model and level of performance (heating). The wall thickness is at least 6 mm steel, or 1 cm cast iron.

- A chimney with good draft that removes carbon monoxide outside the house.

- A water “jacket” designed to cool the combustion chamber. Water is located inside the double walls of the firebox and when the temperature rises, it is forced into the heat pipe and, when cooled, returns back. The “circulation” takes place through the pipes (upper and lower). In this case, the “shirt” should not be confused with the water circuit.

- Air supply control system and long-term combustion power control system.

Depending on the material, wood-burning boilers can be steel or cast iron. The former, at a relatively low cost, require that the temperature in the heat pipe along which the “jacket” runs does not fall below +60°C. This can be solved by installing special valves. Cast iron equipment is purchased when it is expected to be used continuously for heating. In particular, they are most often installed with their own hands in industrial premises.

In addition, such equipment can be divided according to the method of supplying firewood - manual or automatic, and according to functions - into standard ones for heating and with a water circuit.

Rice. 2

Rice. 2The principle and features of the operation of wood-burning boilers

The principle of operation of a long-burning wood boiler is very simple: dry firewood is loaded into the combustion chamber (with your own hands or automatically), and then ignited in any way. The high heat transfer of the boiler is due to the fact that the wood loaded into the firebox does not actually burn, but slowly smolders. The energy released is an order of magnitude greater than during bright, rapid combustion. The smoldering process of firewood is slowed down as much as possible thanks to the air supply through the ash pan located below.

All ash (mineral waste) from burned fuel falls into the ash pan, which requires periodic cleaning. In conventional stoves, when burning, carbon monoxide with soot particles is sent into the chimney. In a long-burning boiler, almost everything burns and a very small amount of non-toxic smoke evaporates. Thus, the residents of the house are safe and in a heated room. By comparison, one of the biggest dangers of a traditional stove is poisoning. carbon monoxide.

Rice. 3

Rice. 3The built-in nozzle allows you to regulate the strength and duration of combustion, stretching it from 5-6 hours to 3 days (Stropuva brand). If the firewood is supplied manually, then it is important to remember that before opening the door with your own hands, you must close the ashpit. Otherwise, the fire that splashes out from the sudden influx of air will burn the person’s hands and scorch his face.

Sometimes boiler owners, to prevent such cases, install a so-called curtain in front of the firebox - a homemade additional damper on a screw.

The main difference between heating boilers long burning using wood from heating with a traditional stove is that long burning of the fuel starts from the top. Air and firewood are also supplied from above.

The peculiarity of this type of heating is also that most of its efficiency is related to the quality of the fuel. The drier the wood, the better heating. The best option acacia and deciduous non-resinous species (birch, aspen, etc.). The worst type of firewood is trimmings fruit trees and unseasoned wood.

Boilers with water circuit

In recent years, long-burning wood-burning boilers with a water circuit, which combine the functions of heating equipment and a water boiler, have become increasingly popular among owners of individual houses.

Their main design difference in heating is that inside the equipment with a water circuit there is a reservoir of water, which, when heated, is displaced into plumbing system at home or in a special container (boiler). In return, naturally heating or using a pump, fills the container cold water, which... and so on until infinity or the end of the service life of long-burning equipment.

A boiler with a water circuit has the same advantages as other wood heating devices. However, the disadvantages of equipment with a water circuit include higher cost and large dimensions. It should also be remembered that it is impossible to speed up the heating of water, since re-supplying fuel to the boiler with your own hands can only be done if the previous batch of firewood has completely burned out. The same applies to the amount of fuel - the water will still not heat up to more than +100°C.

Rice. 4 Wood-burning design diagram

Rice. 4 Wood-burning design diagram boiler with water circuit

Homemade heating boiler: materials and tools

Making a long-burning wood boiler with your own hands is much easier than it seems. Of course, such heating equipment will not have a warranty and the service life will be significantly less than 15 years. However, such an idea will allow one to avoid significant expenses, since in many Russian households heating is required not only by a residential building, but also by numerous outbuildings(bathhouse, garage, shed, etc.). Homemade heating In terms of efficiency, they are in no way inferior to the factory one.

For heating equipment installation simplest design do it yourself you will need the following:

- Metal barrel for 200 l or steel pipe diameter 50-80 cm and length 80-100 cm, respectively.

- Metal corner and sheets of steel with a thickness of 5 mm or more.

- A metal circle with a minimum thickness of 50 mm, which will separate the firebox from the ash pan.

- Doors for the furnace hopper and ash pan.

- Water pipes of different diameters.

- Tank made of galvanized or stainless steel.

- Fittings.

Among the tools for DIY work, you will need a grinder, welding machine and protective equipment when working with welding and metal (goggles, mask, gloves, etc.). The cost of a homemade long-burning boiler is approximately 1000 rubles, excluding labor.