Ceramic heating element. Order ceramic flat heaters from Elektronagrevo with delivery throughout Russia. Devices with a ceramic heating element.

Unfortunately, central heat sources are not always fully capable of performing their assigned tasks. Therefore, it is often necessary to resort to additional method heating Heaters that are available on the market help solve the problem. the widest range. One of these devices is ceramic heater.

Infrared ceramic Edison lamps

Like all models in our hydronic heating program, our “classic” heating is also subject to constant quality control.

- Extremely easy to operate.

- Made in Germany 5-year warranty.

Their ability to independently adapt to the grid without having to make changes to the electrical network in the home makes them unique throughout the world. Some ceramic materials are electrically semiconducting and can therefore be directly heated by electric current. Compared to metal thermal conductors, very high density energy. In addition, the strength and rigidity of ceramics remain virtually unchanged even at extremely high temperatures.

Design features and operating principle

The basis of this type of heating technology is ceramic. Moreover, it can be used in completely different heating devices that differ not only appearance, but also the principle of operation.

Based on the method of heat supply, devices are divided into:

- Infrared ceramic heaters - heat objects using infrared radiation;

- Ceramic convectors operate on the principle of forced convection.

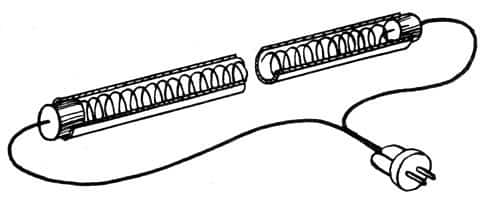

Ceramic IR heaters are equipped with a ceramic heating tube with a nickel-chrome-plated spiral inside. They can be hollow, volumetric or gas. Although such devices are considered the best among analogues, they are not used as actively, because they are capable of heating only a certain area located in the range of infrared rays.

They are distinguished by a relatively low temperature dependence of electrical resistance. In particular, it is also possible to integrate porous materials, such as ceramic foams, as active or passive components in heating elements. This makes it possible to provide very specific and technology-optimized heating systems. Particular experience has been gained in the field of construction and connection technologies for ceramic heating systems, so the work is carried out from concept to production of complete heating systems.

Today, there is great interest in (slabs), which can provide heat to a large area. The peculiarity of heating is that the ceramic plate acts in two directions simultaneously: as a convector and as infrared heater. Inside the structure there are small fans that drive air masses through a ceramic heat exchanger and evenly release the already heated air flow into the room. The ceramic hob has a built-in thermostat that allows you to set optimal temperature and protecting the device itself.

Development and implementation of a concept for ceramic heating systems Development of materials to adapt electrical resistivity Manufacturing of materials and components from dense silicon carbide and silicon carbide composites Manufacturing of materials and components from porous and foam ceramic materials from silicon carbide Special design and technology for joining ceramic heating elements and carbide materials with ceramic or metal components Characterization and testing of heating element materials and heating elements. Thermal conductivity test bench for specific testing of heating elements.

- Complete technologies and equipment for the production of materials and components.

- Ceiling mounted cathode plasma heater for extreme temperatures.

Classification by energy source

Heaters can run not only on electricity, but also on liquefied gas.

Depending on the energy carrier, ceramic heaters are:

Electrical. The most practical and common. Due to their simplicity and ease of use, electric ceramic heaters are often used to heat children's rooms. They do not dry out the air and do not consume oxygen. In addition, they can be used in places with high humidity air.

This heat is then introduced into the material by heat transfer across the surface of the material. Electrical resistance heating is a long-known process. However, or because of the extensive knowledge about this technology, a large number of innovative applications are still possible. For example, it is not possible to produce microelectronic circuits without electric heating furnaces. In addition to optimal use modern materials, the systems themselves are characterized by continuous, user-friendly control and regulation devices, as well as flexible modern systems automation and power supply, which leads to even more best results production at industrial use systems

Gas. They operate using energy obtained by burning high-calorie propane-butane and are somewhat inferior in efficiency to electric ones, although they are cheaper. The main component of the device is ceramic panel, inside which flameless combustion of fuel occurs. A gas ceramic air heater involves the use of a gas cylinder, from which fuel is supplied to the burner through a hose. Most often, such units are used for heating verandas, summer cafes, garages and warehouses.

Projectors for ceramic heaters

It is known that Electric Energy is converted to heat in each current-carrying conductor due to its resistance. Although this effect results in energy transfer losses and is suppressed as much as possible, it can be exploited by specially designed heating devices. The current can flow through the material to be heated or into so-called heating elements.

Heating elements are electrical conductors that are designed in such a way that they release maximum heat. This is transferred by heat transfer to the heated material. Heating is indirect, i.e. heat is generated outside the material and reaches the workpiece inside its surface. Heating elements used in industrial ovens, differ mainly in shape and material. The latter determines the maximum temperature of the application. Heating conductor materials can be divided into two main groups: metal and ceramic.

Classification by type of accommodation

According to the type of installation, ceramic heaters are:

Tabletop devices are compact in size, which, as a rule, have low power and are intended for quickly heating small rooms.

Wall heaters resemble an air conditioner from the outside and can be installed at any height. This ceramic heater does not take up useful space and is most suitable for heating a medium-sized area.

Classification by type of accommodation

Metal heating materials. Metal heating elements should be used in various options implementation in industrial ovens. The best known and most preferred form of application for maximum application temperature and service life is placement on ceramic support pipes. Pure metals are usually placed in curves or loops in the oven. In addition to classic shapes and suspension devices, metal heating elements are also integrated directly into radiant tubes or insulating blocks.

Floor-standing options are the most powerful and are capable of heating rooms of varying sizes.

Advantages

The advantages of heaters with ceramic elements include high efficiency, safety and reliability of use, creation of an optimally comfortable microclimate, quick heating of the room. In addition, compared to traditional ones, they consume one third less electricity.

How does a ceramic home heater work?

Chrome-nickel alloys. Chrome plated nickel heating elements are made from an alloy with an elemental content of 80% nickel and 20% chromium. These types of heating elements have already been used in industrial furnaces as well as in household appliances at the beginning of the century. Chlorine and, above all, sulfur lead to a decrease in heat resistance and, therefore, service life.

Ferritic chromium-iron-aluminum alloys. In addition to the traditional production of these heating wires, chromium-iron-aluminum alloys are also processed by a powder metallurgist. As a result, significantly improved resistance to heat and creep can be achieved, resulting in higher dimensional stability, lower aging tendency and therefore longer service life.

Ceramic heaters have high level fire safety. Thanks to the built-in thermostat, protection against overheating is provided. Among other things, such heating devices are the only ones that can be used in rooms with high humidity. Many models are equipped with antibacterial protection and an ionizer.

Heat fan functionality and safety system

The principle of high hot strength of chromium and iron-aluminum alloys is based on the oxidation of aluminum by the oxygen of the furnace atmosphere in aluminum oxide on the surface. This phenomenon also explains that these heating elements achieve the highest application temperatures and lifetimes in air. Impurities such as oil, dust or vapors lead to a reduction in the element's load and therefore its service life.

Molybdenum and tungsten alloys. Due to the enormous cost of these heating elements, the application is focused on certain areas. These include chemically shrinking applications, high vacuum technology as well as sintering technology, i.e. areas where chemical attacks on others may occur Construction Materials, or increased surface area of the heating conductor and insulating material, for example, present in graphite materials, has a disturbing effect.

An additional advantage of ceramic heaters is the ability to use them as a fan during the hot season.

Flaws

Like all other heating devices, a ceramic heater has its drawbacks. These include the local action of a number of models, as well as the rapid cooling of the room after the device is turned off. Many buyers are confused by the fact that the price of ceramic heaters is significantly higher than others heating devices. In fact, with so many benefits, it makes perfect sense.

Materials of ceramic heating conductor. Resistivity in the zone central heating significantly higher than in cold zones, so that most of the heat is created in the heating zone. Similar to the high temperature aluminum or silicon oxide layers of the already mentioned heating conductor materials, the silicon present in the material forms a quartz layer. Nitrogen, argon or hydrogen atmospheres significantly reduce the maximum temperature of the element.

Types of ceramic heaters

For use in oxidizing atmospheres, these heating elements can be equipped with oxidation-resistant protective layers. Shapes of heating elements with electrical resistance. In addition to the material, the heating elements differ in their shape. Metal elements made of wires or tapes different diameters and width. Metal elements are characterized by their mechanical strength, easy to adjust and inexpensive. They can be hung freely, stored on load-bearing structures or built into beams.

Many people ask the question: in what cases is it worth buying ceramic heaters? Reviews indicate that this climate control technology is excellent for heating bedrooms and children's rooms, as it practically does not dry out the air. Some people prefer to use ceramic fixtures in the bathroom because of their resistance to moisture.

In addition to reels, snakes, etc. Many items are available for use. Ceramic heating elements are manufactured in standard versions. In general, ceramic elements require more complex control than metal elements. Moreover, they are mechanically relatively sensitive. For installation ceramic elements systems are available that provide a wide range possible applications. The main advantage of ceramic elements is the high application temperature.

Ceramic electric heating panels

For multi-phase connections, multiple connections with multiple legs are available. For such elements, several simple rods are connected at one end by a short crossbar. Molybdenum disilicide elements are mainly used in high temperature applications. They require special, mostly hanging, installation methods as they soften as they work. In addition to high application temperatures, they have a long service life.

However, it is important to understand that a ceramic heater, due to its power characteristics, cannot completely replace the main heating system. He can only complement it.

When choosing a device for additional heating, you first need to consider the area of the room. Based on this, it is selected optimal type climate control technology and its power. So, ideal option for a small room it will be wall heater, which will save space and warm it up effectively. In addition, the degree of enclosure of the room should be taken into account: electric ceramic appliances are suitable for internal heating, and gas appliances are suitable for outdoor areas.

To achieve maximum long term The service life of the heating elements must be maintained at maximum permissible temperature element. Element manufacturers provide guide values for two parameters, element load and wall load. Element load is the power density at the surface of the element. In principle, the maximum power density at the surface of an element increases according to the Stefan-Boltzmann law with the fourth power of temperature. In practice, it is strongly limited by back radiation from the furnace walls and heating material.

Many household appliances contain parts that are necessary to heat them and environment. Depending on the area of use and the material of manufacture, there are different heating elements.

Device classification

A heating element is a part of the mechanism of a certain device that is used to heat the environment, a specific device or substance. The diagram of a simple boiler looks like this:

The wall load is the power density concentrated on the surface of the furnace wall. For correct and uniform temperature distribution in the oven, sufficient wall surfaces must be available. The permissible element load and wall load values decrease as the oven temperature increases. They also depend on the type and location of the heating elements.

Types of ceramic fan heaters

Summary and comparisons. Electric resistive heating elements are sold in various materials, depending on application and temperature. In this case geometric shape supplies are hardly limited. In closed, indirect heating furnaces, controlled process atmospheres can be realized. Reliable and simple designs provide a high level of reliability and reliable operation, so that the heating elements can also be changed during system operation with an appropriate design.

Photo - boiler diagram

There are these types of parts:

- Open(Lukey);

- Closed (Galant), X-DUOS);

- Sealed (RTS - PTC, ENGL-1).

Open heating micathermic elements (STIC) are most often made of nichrome. For example, like portable heaters or boilers. Nichrome wire screws on top of the metal work surface. Sometimes a manual heater was even used; it could easily be made with your own hands; a piece of wire was passed through wooden holders and connected to the power supply.

Photo - an example of using nichrome thread

Previously, every electrician had in his supply a decent number of coils of wire of the most different sections. Thanks to simple calculations, it was possible to quickly calculate how much and what kind of wire needed to be wound to obtain a certain power.

Photo - wire diameter and required power

But open heaters have very many shortcomings:

- High fire hazard. If a little dust gets on the hot wire, a spark may appear and a fire may start;

- High probability short circuit. Some craftsmen turn on several similar heaters from one outlet, which greatly overloads the network;

- Low efficiency. Such wire heating elements are considered extremely uneconomical.

Despite the fact that such a household boiler can be made in a matter of minutes, now they are used extremely rarely.

Photo - heating film

Such heating means have been replaced by tubular heating element or heating element, which is currently used for the boiler, washing machine, boilers and other appliances. heating element is closed pipe, in which a contact or thermocouple is placed. There are two types of heating elements: “wet” and “dry”. Wet ones come into contact with liquid, so they often suffer from the harmful effects of water on the metal. Dry ones are protected from it by a special surface, a wall. They take a little longer to heat up the water, but have a much longer service life. On average, wet heaters are replaced every year.

These devices are rarely used for heating, but they do an excellent job of heating water. The main working part is also a nichrome spiral, but it is protected by a tube. Accordingly, there can be no contact with her. The free space in the pipe is filled with certain chemical compounds, resulting in the formation of a dense and closed tube.

Heating elements are now often equipped with a thermostat.

Sealed heaters- these are the same heating elements, but they are completely closed from environmental influences, not counting 2 contacts. Used to heat water, various surfaces etc. The ceramic heating element is safe, heats up quickly and maintains temperature well.

Photo - heating element for stove

Heating elements can also be classified by area of use; they are used for ovens, electric stoves, convectors and soldering irons different types. For brass and hob flexible spirals are used. They can cover a large area without compromising the integrity electric arc. The oven, air fryer and incubator use the same type of heating elements, but with different power parameters.

Kinds heating elements for stoves:

- Cast iron pancakes;

- High Light;

- Halogen.

Cast iron Heaters are used in the simplest stoves and ovens. They can be located at the top of the cabinet or at the bottom. Under cast iron stove there is a spiral made of chromium, nickel and other conductive alloys, sometimes silicon carbide heating elements (SEC). Thanks to this design, the disk heats up for a long time, but at the same time cools down slowly.

High Light- This is an infrared heating tape element, often such a 12-volt carbon heater is used to heat an incubator or small room like an electric convector (Double-U-Force). The ring tape heater can be installed for household convectors, electric ovens, ovens, Wasteland toasters.

Halogen and quartz heating elements are used in most modern electric stoves. They are known for their high heating and cooling rates, which ensures high temperature and device security. High temperature coils are often compared to gas burners, because they heat up quickly and work strictly until they turn off.

Photo - heater made of nichrome and tube

To improve the operation of heating devices, they are often used additional elements, for example, for muffle furnace These are electric annealing heaters, and for boilers - special thermal layers. Such thick film “wraps” help maintain the temperature balance at a certain level even after turning off the power. A thermos effect is created without heating the air.

Video: heating elements for soldering equipment

Repair and replacement

Electric flat and flexible heating elements of a water heater, thermopot or electric furnace break quite often. Their repairs should be carried out by a specialist, but some work can be done by yourself. Industrial heaters tend to burn out due to high loads, while low-voltage carbon or carbon spiral elements of washing machines and boilers burn out due to scale.

In most cases, you can simply replace the part with the same one. For example, many companies that produce boilers (Termex, Bosch) offer their customers wide choose products. But sometimes, say, to make a thermostat, you need to calculate the resistance of resistors and voltage. Let’s assume that to operate some abstract device (let it be a heater for plants, a generator for a mirror or a car steering wheel), you need a power of 20 watts and a voltage heating element 12 Volt. It turns out that the current will be within 1.2 (20/12).

Photo - heating element from a washing machine

Hence, the resistance will be 7 Ohms (12 * 1.7). You will need about 40 resistors, it is advisable to take one-watt ones. The sum of their resistance should be 7 Ohms, based on this, they need to be connected combined method to get the desired result.

This calculation can be used for repairs blowtorch, automotive components or a small heater. But what if the heating element of the washing machine or boiler stops working?

How is the replacement made? Heating element in the boiler:

- First you need to find out where the heater is located. It may be located on the underside of the cover or on the side, depending on the design. This is described in detail in the user manual;

- You need to turn off the water in the boiler and, if possible, drain it by simply opening the tap (some brands make water heaters protected, i.e. the liquid cannot be drained from them). Be prepared for this and place a container near you in advance to collect water;

- Then unscrew all the bolts near the cover and carefully remove it;

- There may be silicone gaskets or clamps under the bolts, be careful not to damage them;

- If the heating element is located at the bottom, it will be removed along with the lid. Sometimes this part is built into the body. You are interested in a needle thermocouple. Old boilers use a cartridge type; it is inserted into the base of the device.

If the water heater has a protective tube, then it will be easy to get the heating element, but if it is of the “wet” type, then you will first need to clean it of dirt and scale. Now just replace the old part with a new one and install everything in reverse order. If silicone gaskets are lost, you can blow out the cracks using a glue gun.

Repairing the heating element of a washing machine is more difficult due to large quantity removable parts. The closed part is very close to the drum, so you need to be careful when removing it. You need to turn the washer over and unscrew two or four bolts (depending on the brand), with outside. Then carefully pull out the part. It is very important not to touch the drum and air filter. In front of you is the most regular heater, reminiscent of old boilers. It needs to be replaced. Sometimes a modern disk analogue is used, but you cannot remove it yourself.

You can buy replacement heating elements at any electrical goods store, the price depends on the brand and technical parameters(it is better to calculate them in advance).