Which gas boiler is the most reliable? Wall-mounted gas boilers: the main differences from the floor-standing type. What to look for when purchasing?

Currently, gas remains the most optimal energy carrier for creating an efficient and reliable heating system. Along with wall-mounted boilers, floor-standing models are used to complete the heating supply. They have a number of specific features that should be taken into account when creating a circuit and installation. Let's consider the main parameters that floor gas boilers for home heating, overview of manufacturers and reviews.

Selection and operation of gas floor-standing boilers

How to determine the best floor-standing gas heating boilers? First of all, you should pay attention to their rated power, equipment and manufacturer. The heating supply to your home must be not only efficient, but also reliable.

It should be noted that domestic floor-standing gas heating boilers are currently practically in no way inferior to their foreign counterparts.

Therefore, the choice is mainly determined functionality equipment and technical characteristics. All gas heating boilers work on the principle of transferring thermal energy from fuel combustion to the coolant.

However, in practice, the value of efficiency and reliability of operation is determined by the following parameters:

- Burner type. Foreign and Russian floor-mounted gas heating boilers can be equipped with a single-stage, two-stage or modular burner. It is preferable to choose the latter option - the flame intensity is adjusted with great accuracy;

- Rated power. This parameter directly depends on the characteristics of the building: its heat losses, the number of window and door structures;

- Price. The most expensive are cast iron floor-mounted gas heating boilers, since this material is best suited for the manufacture of the body and heat exchanger.

An important role in correct operation The organization of the equipment installation site plays a role. Thus, floor-standing double-circuit gas heating boilers must be connected not only to heat supply mains, but also to DHW pipes. Conditions for premises and equipment can be obtained from Management Company. Upon request for installation of gas equipment, it is obliged to issue complete Specifications. Only after this is the gas connection connected floor boiler to the heating system.

To save money and subject to availability solid fuel boiler You can modify it by installing a gas burner. It is important that the heat exchanger is designed for increased temperature levels, and the chimney pipe provides the required level of draft.

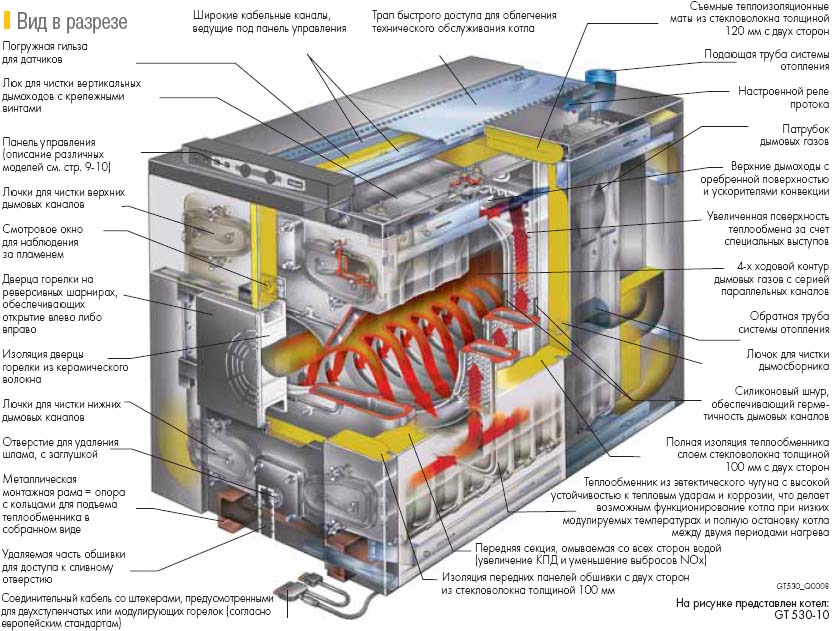

Types of heat exchangers in gas floor-standing boilers

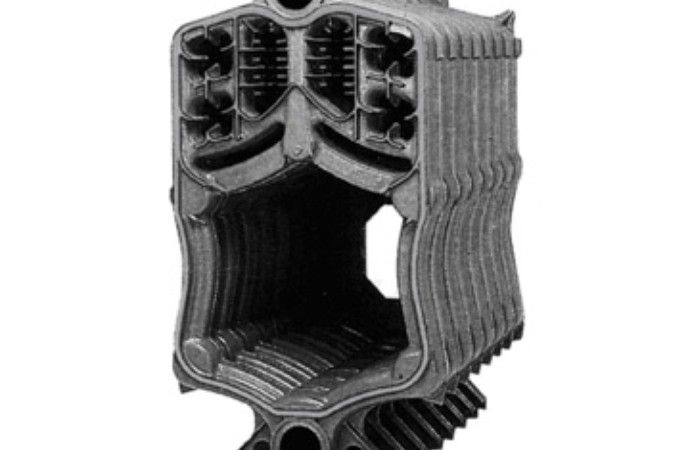

One of the determining parameters for boilers is the material used to make the heat exchanger. Many Russian and Ukrainian floor-mounted gas heating boilers are equipped with steel heat exchangers. But to increase service life and improve technical characteristics, it is recommended to choose cast iron models.

Characteristic for cast iron gas heating boilers long term services. They are less susceptible to rust and scale inner surface walls However, along with this, one must take into account the important disadvantage of a cast iron heat exchanger - its large weight and dimensions. As a result, this affects the size of the boiler.

It is because of this that floor-standing double-circuit gas heating boilers rarely include cast iron components. The problem lies not in the complexity of manufacturing a double heat exchanger, but in its weight and dimensions. In addition, the consumer should know the following distinctive properties of Russian gas floor heating boilers with a cast iron heat exchanger:

- Susceptibility to damage from strong impacts. Cast iron has virtually no ductility. Therefore, under mechanical stress there is a high probability of cracks and chips;

- Sudden temperature changes have a negative impact. This is relevant in those heat supply systems where changes in the coolant flow are possible. Overheating of the housing or a sudden change in water temperature will cause loss of tightness;

- High heat capacity. After connecting a gas floor-standing boiler to the heating system, heating of the coolant will be slower than with a steel heat exchanger. But after turning off the gas heater, the water will continue to heat up for some time.

In most cases, non-volatile floor-mounted gas heating boilers are equipped with steel heat exchangers. This type of device does not require an electrical connection. The burner is ignited by a piezoelectric element. In this case, the choice of a steel heat exchanger is determined by its relative cheapness and lighter weight. However, the service life of such models is 10-15 years.

The best floor-standing gas heating boilers have a heat exchanger made of copper. This optimal material, but it is much more expensive than cast iron or steel. Therefore, such models are becoming increasingly rare.

Types of gas floor boilers

For selection optimal model Ukrainian gas floor heating boilers or manufacturers from other countries should pay attention to the technical data of the equipment. One of them is the rated power of the boiler.

The optimal power for a particular heating system is determined through complex calculations. The heat losses of the house, the climatic features of the region, and the recommended thermal operating conditions of the equipment are taken into account.

For foreign or domestic floor-standing gas heating boilers, the power should not be lower than the calculated one. Experts recommend purchasing a model with a small margin of 10-15%. If it is larger, fuel consumption will increase, which will affect the efficiency of the entire system.

Regardless of the choice of floor-standing cast iron gas heating boilers or their steel analogues, a number of factors must be taken into account:

- Number of circuits. If there is no need to provide hot water supply, you can choose a single-circuit model. For hot water supply, you should purchase a double-circuit floor-standing gas heating boiler;

- Atmospheric or closed burner. In the first case, air to support the combustion process comes from the room. But to reduce the likelihood of combustion products entering living rooms It is recommended to purchase models with a closed burner. A coaxial chimney is installed for them;

- Possibility of adjusting flame intensity. Modular burners have the best efficiency indicators. But they are highly expensive. For heat supply small house or a dacha, you can connect a gas floor-standing boiler with a two-stage burner to the heating system;

- Electrical connection. Eat whole line non-volatile gas floor heating boilers that do not require electricity. However, their performance indicators are slightly lower than those of electric models. This is due to the lack of electronic control components.

In the vast majority of cases, domestic floor-standing gas boilers for heat supply are technically no different from their foreign counterparts. Therefore, with the same performance characteristics, floor-standing gas heating boilers of Russian or Ukrainian production are most often chosen.

Before purchasing a floor-standing non-volatile gas boiler heating please inquire about availability service centers for its maintenance. This information will be useful in case of equipment failure or for obtaining informational assistance.

Floor-standing gas boilers Buderus

The products of this German company appeared on the Russian market relatively recently. But in a short time, Buderus floor-standing gas heating boilers have gained great popularity among domestic consumers.

A feature of the company's products is consistently high quality. All types of Buderus floor-standing gas heating boilers are equipped with cast iron heat exchangers. Thanks to well-thought-out ergonomics, this does not greatly affect the overall dimensions of the equipment. It is also worth noting the range of products.

Currently, Buderus offers floor-standing gas boilers with capacities from 20 to 270 kW. They are suitable for organizing heat supply for a private home, office or industrial building.

Floor-standing gas boilers for heating Buderus have the following advantages:

- Possibility of connecting an external heater tank;

- Changing nozzles for using liquefied gas;

- Push-and-turn control setup;

- Installation additional modules to optimize boiler operation.

The average cost of a 20 kW model is 80 thousand rubles. Due to the ease of connection, the price of commissioning work for the company’s gas boilers is one of the lowest on the market. However, it should only be carried out after all permitting documentation has been completed.

Boilers with a power from 73 to 270 kW can operate in low temperature mode. This will save on fuel consumption, which is important when organizing heat supply for large premises.

Zhukovsky floor-standing gas boilers

The Russian manufacturer Zhukovsky Machine-Building Plant offers reliable and affordable heating equipment. Extensive experience (about 40 years) and a modern technical base made it possible to launch the production of a large assortment of Zhukovsky floor-standing gas heating boilers.

Boilers of the AOVG and AKVG series are designed for the installation of energy-independent heat supply systems. The company offers several variants of models that differ in configuration. The rated power of the equipment varies from 11 to 68 kW. Due to their affordable cost, Zhukovsky floor-standing gas heating boilers have become popular in heat supply systems small rooms- dacha, outbuildings etc. In addition, they are successfully used in the heat supply of residential, administrative and industrial buildings.

When choosing Zhukovsky floor heating gas boilers, you should pay attention to their equipment:

- Economy. The equipment uses a Russian-made automation unit;

- Station wagon. To control the operation of the boiler, foreign components are used;

- Comfort. Possibility of connecting a room thermostat and remote control.

The main advantage of boilers from this manufacturer is their affordable price. One of the most popular models of the “Universal” class with a power of 20 kW will cost about 22 thousand rubles.

The heat exchanger in the boilers of the Zhukovsky plant has a tubular shape. Its reliability is ensured by seamless welding technology steel pipes. The secondary heat exchanger for DHW is made of copper.

Floor-standing gas boilers from the Lemarks company

The Russian trading and production company Lemarks offers consumers one of the widest ranges of floor-standing heating boilers. Using modern technologies and constantly improving production capacity, the company managed to become one of the leaders in sales of heating equipment. That is why the Lemarx floor-standing gas heating boiler can be found in heat supply systems for private homes and large buildings.

The consumer has the opportunity to choose both single-circuit and double-circuit models. The automation of Lemarx floor-standing gas heating boilers is manufactured using the SIT system, which ensures a high degree of reliability and a long maintenance-free service life.

There are two types of heat exchangers for boilers - steel and cast iron. For technical and information support, the company has a large network of representative offices and service centers.

Currently, there are the following types of floor-standing gas heating boilers Lemarks:

- Premium. Made from steel 2 mm thick. Power - from 7.5 to 80 kW;

- Leader. Gray cast iron 4 mm thick is used for production. Rated power – from 16 to 50 kW;

- PremiumNova. Additionally equipped with automatic equipment 820 Nova SIT;

- Gazovik. The boiler includes an Italian gas burner "Polidoro".

The average cost of a Premium boiler is 26,150 rubles.

A feature of Lemarx boilers is their inexpensive service maintenance. Even after the warranty period has expired, the consumer can count on high-quality repairs heating unit.

Floor-standing gas boilers Conord

In the economy segment of heating equipment, Conord floor-mounted gas heating boilers have proven themselves well. In 2012, the Russian company carried out a comprehensive modernization of the production line - Japanese-made Amada equipment was installed. This allowed us to reach new level product quality.

The standard equipment of Conord floor-standing gas heating boilers includes a steel heat exchanger; the body is made of steel sheets 2 mm thick. An innovative component is the design of the smoke collector - it allows you to use the heat from carbon monoxide to heat the coolant. Autonomous operation can be considered an important advantage DHW circuit, which is especially important in the summer.

The range of floor-standing gas boilers for heating Conord can be divided into the following groups:

- Without DHW with automatic SIT;

- Without DHW with thermo-hydraulic automation;

- With DHW with automatic SIT;

- With DHW with thermo-hydraulic automation.

An undoubted advantage is the more than affordable cost of heating equipment. The price of one of the most popular models with a power of 20 kW with a hot water supply circuit and thermo-hydraulic automation is 23,000 rubles.

Conord boilers can operate even at a low pressure of 0.6 kPa. This advantage can be used when organizing a balloon gas heating private house or cottage.

Gas floor-standing boilers from Protherm

The boilers of the Czech company have always been different good quality and choice of models. Specializing in the production of heating equipment, Protherm Lately expanded its product range. That is why floor standing boilers Proterm heating products occupy a leading sales position.

The company offers several models of underfloor heating equipment - “Bison”, “Bear” and “Grizzly”. They differ in rated power, configuration and materials used.

All Proterm floor-standing heating boilers are equipped with an open burner. The difference lies in the ability to regulate the flame intensity - two-position or modular. It is also recommended to pay attention to the material of manufacture of the heat exchanger – cast iron or steel.

There is a certain classification of Proterm floor heating boilers:

- KLZ. The boiler has a double-circuit cast-iron heat exchanger and a built-in hot water tank with a capacity of 90 l;

- TLO. A non-volatile model that does not need to be connected to the mains. There is no storage tank and DHW circuit;

- PLO. It is equipped with a single-circuit cast iron heat exchanger and a two-stage burner. As an additional option, a forced smoke removal system can be installed;

- KLOM. The model includes a complete set - a cast iron double-circuit heat exchanger, storage tank, modular burner.

For heating large industrial or commercial areas, it is recommended to use the Bison model. It is equipped with an external gas burner Lamborghini with power from 75 to 3500 kW.

The company offers an annual maintenance service for its heating equipment. This minimizes the likelihood of failure of the gas heating boiler.

Floor-standing gas boilers from Vailant

The brand of heating equipment “Vailant” is known to Russian consumers mainly for wide range wall-mounted gas boilers. But the product line also includes floor-standing gas heating boilers Vailant.

A series of underfloor heating equipment is represented by ecoVit boilers. They differ from competitors by using carbon monoxide condensate reheating technology. This allows you to increase the nominal indicator of Vaillant to 98-99%.

All models are equipped with a modular gas burner; a layered DHW heating system significantly reduces the temperature rise time. Depending on the customer’s wishes, you can choose a boiler with various systems control - an electronic programmer, the ability to connect external temperature sensors.

The advantages of floor-standing gas boilers for heating Vailant are as follows:

- Choice of models with power from 22 to 47 kW;

- The multisensor system provides regulation of the gas combustion process, reducing its consumption;

- Wide range of burner modulation from 20% to 100%.

After connecting the boiler, its operation is adjusted in automatic mode. The equipment automatically adjusts the parameters to the actual pressure and type of gas.

Vailant boilers can be installed in a cascade scheme. The maximum number of heating equipment is 4.

Today determine which gas boiler is better, It's hard enough. Since almost all devices of this type have a fairly large resource and are very convenient to use. Before going to the store, the buyer needs to decide what type of equipment he needs. All of it can be divided into the following categories:

Single-circuit boilers

The most popular today are gas boilers from the following manufacturers:

- Ferroli;

- Bosch.

The Ferroli company is of Italian origin. Boilers from this brand have a rather unique appearance; they are very compact and at the same time ergonomic. They have convenient controls. The most popular series from Ferroli is Domiproject. Its most important advantage is the ability to choose a specific model based on power indicators. Modifications are presented that produce from 12 kW to 21 kW.

The most popular model today is the Ferroli Domiproject C24 (Fig. 1). It has the following parameters:

- expansion tank volume - 6 l;

- power - 24 kW;

- height - 700 mm;

- width - 400 mm;

- depth - 230 mm;

- weight - 25 kg.

Fig.1. Gas boiler Ferroli Domiproject

The most important advantages of this device include a built-in effective security system, as well as electric ignition. The automated control system makes it possible to program the device for a long period of operation. Present a large number of options. What attracts buyers most about this model is its compactness and light weight - installation does not cause any difficulties, it can be done alone. Also small size will make it easy to place the boiler in a niche or hide it in another way.

To the disadvantages of this device can be attributed to “weak” electronics. The fact is that it is quite sensitive to voltage surges in the electrical network, so sometimes it fails for this reason. The flow sensor also often gets clogged. In general, the model under consideration is quite economical. But the most important thing is that its price is low, especially relative to its German counterparts. (Fig. 2)

Fig. 2. Ferroli Domiproject gas boiler

Better quality and more functional, but at the same time expensive - single-circuit boilers manufactured by Bosch. The most popular budget model is Gaz 6000 W (WBN 6000-18 H) (Fig. 3). It has the following parameters:

- expansion tank volume - 8 l.;

- power - 24 kW;

- height - 400 mm;

- width - 299 mm;

- depth - 700 mm;

- weight - 32 kg.

Fig. 3. Gas boiler Gaz 6000 W (WBN 6000-18 H)

The only thing in which the Gaz 6000 is inferior to a similar model from Ferrolli is its dimensions. Products from Bosch are somewhat larger and weigh as much as 10 kg more. The cost of these two models is also significantly different. If Domiproject will cost the buyer only 28 thousand rubles, then the minimum price of Gaz 6000 is 36 thousand rubles. In other respects, Bosch products are superior to their competitive counterparts.

First of all, this concerns productivity and efficiency - it is more than 95%, while Domiproject is only 91-93%. At first glance this seems like a small amount. But at very long-term operation this results in quite large volumes. It is also worth noting that the Gaz 6000 has extremely reliable electronics as well as an automation system. Therefore, you can leave your home heating equipment running for a long period without any fear.

Despite the heavy weight and relatively large dimensions, installation of Gaz 6000 does not cause any problems. Since there are special eyes on the body, and the complex always includes anchor bolts. In general, the model under consideration is more reliable and functional. Therefore, if financial possibilities allow, then it is worth purchasing it, since subsequently you can forget about maintenance and repair for a long time. In addition, Bosch products have a built-in pump that creates the required pressure in the heating system (Fig. 4).

Fig.4. Gas boiler pump Gaz 6000 W (WBN 6000-18 H)

If the issue of price is very important, then you should pay attention to products from Ferrolli. It is less reliable and has some weak spots(heat exchanger, sensors). But at the same time, its cost is sometimes 1/3 lower. Choose best gas wall boiler possible with the help of a sales consultant.

Double-circuit boilers

If, in addition to heating, it is also necessary to supply hot water, then you need to focus your attention on a double-circuit boiler. Relatively new on the market Russian Federation products from the Kiturami company appeared. The homeland of this brand is Korea, but the quality of these products is at the highest high level. One of the most popular models in the mid-price segment is Twin Alpha 20R (Fig. 5). It has the following parameters:

- power - 23 kW;

- weight - 28 kg;

- width - 430 mm;

- height - 730 mm;

- depth - 210 mm.

At the same time, the cost of this gas heating installation is only 29.9 thousand rubles. Power of this boiler allows the base of any difficulties to heat an area of 180 m2. At the same time, heating of the coolant occurs extremely quickly. The overall dimensions of this model are relatively small, especially considering that it is dual-circuit. This allows you to carry out the installation process without any difficulties.

The disadvantages include the relatively low efficiency. It is 92%. Many similar models with the same performance demonstrate an efficiency of 95%. But taking into account the fact that this model has a domestic purpose, this point does not play a big role. It is also not very convenient to configure the device and some other actions, since the control panel is poorly located. Despite some shortcomings, the boiler overall is a good choice.

If you require the highest quality and reliable heating system gas technology, then you can opt for one of the models from Buderus company. This manufacturer offers gas boilers very High Quality. One of the most popular is Buderus Logamax U054T ( rice. 6). The boiler has the following parameters:

- power - 24 kW;

- width - 600 mm;

- height - 880 mm;

- depth - 475 mm;

- heat exchanger capacity - 42 l.

Fig.6. Gas boiler Buderus Logamax U054T

There are few disadvantages to this type of product. First of all, the cost is quite high. The price of the equipment is as much as 84 thousand rubles. This amount will be enough to purchase 2-3 gas boilers of a lower class. But this cost is completely justified. Since, having purchased Logamax U054T, its happy owner does not have to worry about repairs. Most likely, it simply will not be needed, since Buderus produces only very good gas boilers.

The most important advantages of this model include the following:

- the ability to heat an area of 240 m2;

- permissibility of operation on both butane and propane;

- convenient and functional control.

The control panel is especially convenient. It includes just a couple of switches, as well as a special digital display - it displays all the necessary information. Many people are not satisfied with the need for chimney equipment. But it is precisely due to its presence that the operating modes supported by the boiler in question are possible. In addition, purchase optional equipment Designing an exhaust pipe is quite simple.

This manufacturer guarantees uninterrupted operation of its products for two years from the date of installation. The service provided by this company is of fairly high quality.

If you don’t have the funds to purchase such expensive equipment as Buderus, then you can take a closer look at cheaper analogues. Many of their performance characteristics are in no way inferior to the Logamax U054T, and sometimes even surpass this model. For example, Electrolux produces good products.

If you need a powerful double-circuit boiler for heating a private house or even production premises, then in this case the GCB Quantum 24i is perfect ( rice. 7). Its characteristics are as follows:

- power - 24.1 kW;

- height - 790 mm;

- width - 480 mm;

- depth - 380 mm;

- weight - 30.5 kg.

Fig.7. Gas boiler GCB Quantum 24i

The relatively high weight is a consequence of the use of durable plate steel for the manufacture of the heat exchanger. Thanks to this, the safety of the equipment in question has become even higher. Small overall dimensions make installation quite simple. The cost of the equipment in question is approximately 35 thousand rubles. The most important advantages of this model include the following:

- the heat exchanger has an increased area, which allows heating of the coolant as quickly as possible;

- there is No-Freez - a system that does not allow liquids to freeze;

- automated heating control, no human presence required (ETC);

- If there is any malfunction, the boiler independently signals this - a malfunction code is displayed on a special display.

The boiler model in question looks extremely attractive. Therefore, you can fit it into almost any room design without any difficulty. It is possible to connect a special thermostat located directly in the room. But the most important feature- this is an opportunity to implement remote control using a special remote control (Fig. 8).

Fig.8. Remote control of a gas boiler

But this model also has some disadvantages. First of all, this concerns the heating rate: in order for it to be high enough, the gas consumption will need to be significantly increased. And this, given the constantly rising prices, is not entirely convenient. At the same time, the efficiency is not very high (90%). At the same time, a similar model from Buderus has a higher efficiency. But, taking into account the cost of Electrolux equipment, this disadvantage you can simply close your eyes. Also, some difficulties may arise with automation. If there is a long power outage or power surges, there is a high probability that the settings will be changed arbitrarily. Therefore, despite the presence of a convenient automation system, you should not leave the equipment in question unattended.

Consumers pay undeservedly little attention to gas boilers produced by Neva. This domestic manufacturer produces fairly reliable equipment with many advantages. But the most important thing is the low cost. For example, a double-circuit boiler with a capacity of 12.7 kW can be purchased for only 25 thousand rubles. Moreover, all models of equipment can operate on various types of gas: propane and butane. All modifications of double-circuit boilers are not sensitive to high and low voltage (187-250 V). This is especially important given the cost and low quality electrical energy on the territory of the Russian Federation.

When choosing a gas boiler, you must first focus on your needs and financial capabilities. But at the same time, you should not cheapen and buy gas installation with not the best performance characteristics. It is best to buy reliable equipment with a significant reserve of power - this way you can avoid the need to purchase a new boiler in the future. It is also worth paying attention to the fasteners, since the installation process in most cases causes many difficulties. It is also important to choose not only heating boilers, but also pipes and the correct insulation for heating pipes.

Choosing a gas boiler. A selection of videos.

Due to the fact that a large number of new, modified models of domestic and foreign production with different characteristics and price levels have appeared in the range of heating devices offered to consumers, nowadays it is possible to replace an old boiler with a more economical, compact and aesthetic one without any problems. Many owners decide to “kill two birds with one stone” with such an acquisition, that is, at the same time solve the issue of autonomous supply hot water. And this is not difficult now - they are offered wide choose double-circuit boilers.

However, such a high saturation of the market often contributes to the “reverse effect”, that is, it makes the choice of the optimal model very not an easy task. We will try to help with this - we will provide a list of devices that are consistently included in the constantly changing rating of double-circuit, wall-mounted and floor-mounted gas boilers. True, a reservation can be made: the authors deliberately did not award certain places to the listed boilers - simply so as not to interfere with the subjective factor in this issue. The defining criterion was positive reviews consumers who have already tried this technique in practice. In a word, the boiler models indicated in the publication can be purchased with close to 100% confidence in receiving a device of high build quality and with the expectation of its long-term operation.

Of course, when choosing any heating boiler, you need to pay attention to other criteria that affect quality and durability.

Basic criteria for choosing a heating device

Unit type by location.

Double-circuit boilers are divided into floor-mounted and wall-mounted.

- Floor-standing double-circuit gas boilers are usually designed for higher thermal power than wall-mounted models, which is why they are most often installed in houses with a large area. However, for such heating devices with a power of 30 kW or more, a separate room from the living area is required. Therefore, before choosing such a model, it is necessary to study not only specifications and operating rules, but also standards for boiler room equipment.

On sale you can find models of floor-standing gas boilers that do not require power to operate - it is only important that a gas supply with natural or liquefied gas is provided. Such variants of units are especially convenient for heating in houses located in rural areas, where power outages are not uncommon. The design of non-volatile boilers is quite simple, but very reliable; such units are more durable than boilers with complex automation.

The efficiency of modern floor-standing models is 90 percent or higher.

- Wall d double-circuit gas heating devices, as a rule, are compact in size, so they are convenient to install in small houses or even in a city apartment.

Since such a unit does not take up much space, it is usually placed on the kitchen wall, where all the communications necessary to connect it are located. For the operation of almost all models of wall-mounted heating devices, it is necessary uninterrupted power supply. Both the circulation pump and the automation unit require power, and, in models with a combustion chamber closed type– fans for air injection and exhaust of combustion products.

Naturally, installing a gas boiler in the living area of the house increases the requirements for the organization more efficient system ventilation.

Unlike floor-standing boilers, in which steel or cast iron heat exchangers are often installed, wall-mounted units, in order to reduce their weight, are often equipped with copper heat exchange elements.

Unit power in wall-mounted version usually varies from 9 to 30 kW.

Power of double-circuit boilers

In order for a heating and water heating device to be truly effective in operation, it is necessary to correctly calculate its power for a specific house or apartment.

Very often on the Internet you can come across a sign like this:

To be honest, such information, instead of a clear idea, can, on the contrary, raise a lot of questions in the consumer. Agree that the difference in price between 9 kW and 20 kW models will be quite significant, and the spread of options according to such a “coordinate system” is impressive.

In addition, this approach does not take into account the characteristics of the regional climate, the building itself and its individual rooms, the degree of glazing (that is, the number and size of windows) and many other important circumstances. Therefore, it seems more reasonable to carry out more thorough calculations, in which the calculation calculator located below can help.

The basic principle is that calculations are carried out for each heated room separately, and then the results are summed up. This, by the way, gives the owners another “preference” - having such calculation results in hand (and it is best to display them on a plate - for each room separately) it will be much easier and correctly to arrange heat exchange devices in the rooms - radiators or convectors.

Calculator for calculating the required thermal power for space heating

When choosing a gas boiler for heating a private home, we are faced with a huge selection of equipment. Buyers can choose from single-circuit and double-circuit models, wall-mounted and floor-mounted, atmospheric and turbocharged, simple and multifunctional. How to understand all this diversity and really do right choice– our detailed review will tell you.

IN this material we will tell:

- About the main types of boilers for heating private houses;

- About the advantages and disadvantages of gas equipment;

- About the features of certain devices.

We will also provide information about the calculation required power and provide user reviews.

Types of gas boilers

How to choose a gas boiler for heating a house is known to every specialist involved in the installation of heating systems. First of all, you need to decide on the basic equipment requirements. Gas boilers are divided into the following categories:

- Wall and floor;

- Single-circuit and double-circuit;

- With open and closed combustion chambers;

- Convection and condensation.

There are also volatile and non-volatile modifications. Let's look at the above criteria in more detail.

The choice of gas heating equipment for heating a private home begins with choosing a place to install the equipment. Everything is simple here - if there is space for a separate boiler room, you can limit yourself to a floor-standing model. If there is room for floor mounting no, we pay attention to wall modifications.

Floor-standing boilers are often made on the basis of reliable cast iron heat exchangers - these models have a significant margin of reliability, they are unpretentious and do not cause problems in operation, practically do not leak and can work long years without failures or breakdowns. In addition, floor-standing models of gas boilers for private homes are characterized by high power - if you have a large household at your disposal, feel free to choose modern floor-standing boilers.

Wall-mounted devices are distinguished by their compactness. In my own way interior design they resemble the most ordinary instantaneous water heaters, only instead of flowing tap water, they heat the coolant circulating through the heating system of a private home. The power of individual models can be very high, up to several tens of kilowatts.

Single-circuit and double-circuit models

To heat private houses, the simplest gas boilers with one circuit are often used. They are extremely different simple device– they contain a burner and one heat exchanger. These units can work exclusively in heating systems; they do not know how to prepare hot water. Such boilers are produced in two versions - floor-mounted and wall-mounted.

Double-circuit modifications combine two units at once - this is a flow-through gas water heater and boiler. Priority is given to the DHW circuit; during its operation, the heating is switched off. The design of double-circuit boilers is complex; there are three way valves, as well as combined or separate heat exchangers. But they are more functional and easier to install and operate.

The main advantage of double-circuit gas boilers used for heating and hot water preparation is their compactness - they take up several times less space than separate equipment.

Before us is another division of gas boilers - they are divided into modifications with open and closed combustion chambers. Models with open cameras combustion is often called "atmospheric" because air flows to the burners by gravity, taken directly from the room in which the equipment is installed. As for combustion products, they are removed through a regular chimney with natural draft.

The main advantages of “atmospheric” models are more simple design, low noise level, energy independence (typical for certain models that are not connected to the mains).

Turbocharged gas boilers for home heating are models with closed combustion chambers. The air for their operation is taken from outside the buildings, through a special two-layer chimney. Smoke removal is carried out through the same chimney. Fans are installed above the combustion chambers, which are responsible for removing smoke and air intake. Boilers with closed combustion chambers can be installed in any premises of private houses.

The disadvantages of turbocharged models are reduced reliability due to a more complex design, noise and increased power consumption (the fan alone consumes about 100 W).

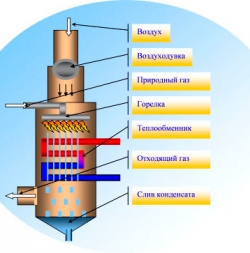

Convection and condensation

Gas boilers for heating a private house are most often built using a convection scheme. It's simple:

- The burner generates thermal energy;

- The heat exchanger takes the resulting heat;

- The heat is sent to the heating system, and its remains are sent to the atmosphere.

As a rule, the efficiency of such boilers varies between 90-93%. Consequently, up to 10% (and sometimes more) of thermal energy simply escapes into the atmosphere.

Condensing gas boilers are built according to a slightly different scheme - here almost all the generated heat is taken into the heating systems. As a result of the work, condensate is formed and sent to the drainage. Developers claim that the efficiency of such units is over 100%, but we know that it is impossible to get more than invested. Therefore, the highest numbers are a classic marketing ploy.

According to data from manufacturers, condensing boilers are able to save up to 10-15% of gas fuel when compared with conventional convection models. In practice these figures may be lower.

Advantages and disadvantages of gas boilers

One of the most important advantages of gas heating is its price, and if there is a gas pipeline next to your house, then there is no point in thinking about other types of fuel.

The use of AGV and gas boilers for a private home for heating purposes promises certain benefits. To begin with, it should be noted that natural gas is cheap - it is cheap, and its combustion releases a huge amount of energy. Operating electric boilers is more expensive, and liquid and solid fuel models are not particularly convenient. Other advantages of gas boilers:

- Fully automated operation – heating on gas equipment practically does not require user intervention and works in automatic mode (only temperature adjustment is required);

- Low fuel costs – this can only be matched by free firewood from the neighboring forest;

- Ready to work at any time of the day or night – just activate the heating on the control panel. The same solid fuel boilers will require preparation for ignition and subsequent cleaning;

- Minimal maintenance - usually performed once a year. But with liquid and wood boilers much more fuss;

- Electrical safety - many models of gas boilers for heating private houses can operate without access to the electrical network.

There were also some disadvantages:

Gas is very explosive, so do not neglect the rules for operating gas equipment.

- Difficulty connecting to gas network– permitting documentation will be required to start the equipment;

- Mandatory, albeit minimal, maintenance - you can’t do without it;

- The gas is explosive - if there is a gas leak, an explosion may occur;

- The need for separate rooms for some types of boilers - e.g. floor-standing stoves with open combustion chambers require separate boiler rooms.

Nevertheless, gas boilers have been and remain an inexpensive solution for organizing heating in private residential buildings.

An undeniable advantage of gas boilers is their ease of use. And if there is no gas mains connected to a private house, then the solution is simple - we use a bottled gas connection. True, its quality does not always meet the standards - because of this, burners, heat exchangers and chimneys quickly become dirty.

Types of heat exchangers

Boilers with copper heat exchangers have proven themselves in the heating equipment market.

If you want to buy a gas boiler for heating a private home, pay attention to the differences in the heat exchangers used. They can be copper, steel, bimetallic and cast iron. Copper heat exchangers are made from purified copper and have good performance characteristics. They can easily carry thermal overload, they rarely leak and are characterized by high heat capacity.

One of the main advantages of copper heat exchangers is their ease of repair - if leaks are detected, they can be soldered with the most ordinary high-power soldering iron.

Steel and bimetallic heat exchangers cannot be called the most reliable and practical solution. They are prone to burning out quickly, and their inner space quickly becomes clogged with waste. Therefore, they are not repaired, but most often replaced. As a rule, steel and bimetallic heat exchangers are installed in the cheapest gas boilers used for heating private houses.

Cast iron heat exchangers are the most reliable and durable. They warm up quickly and cool down slowly, tolerate temperature overloads well, and are resistant to corrosion. Cast iron is perfect material for such purposes, but care must be taken when installing equipment, since the alloy is somewhat brittle.

Cast iron heat exchangers are used in floor-standing gas boilers for heating private homes. Equipment built on their basis can have very high power (up to hundreds of kilowatts).

As for double-circuit gas boilers, they come in two types:

- With dual heat exchangers;

- With separate heat exchangers.

The double design is good because it is cheap. Such boilers have one heat exchanger; it is responsible not only for heating, but also for the operation of the DHW circuit. But this scheme has a drawback - low reliability. In addition, the double heat exchanger often becomes clogged with scale, losing its functionality. Therefore, only the cheapest boilers are equipped with such exchangers.

Gas boilers with separate heat exchangers have more complex circuit– here heat generation is carried out in the main heat exchanger (steel or copper), and hot water is prepared in a separate plate exchanger. In this case, the secondary exchanger does not come into contact with the burner flame; it is generally located in a different place - heating is carried out using part of the coolant.

Design features

We have already said that gas boilers for heating private houses can be single-circuit and double-circuit, convection and condensation, wall-mounted and floor-mounted, atmospheric and turbocharged. But there are other differences represented by some design features.

Automation

Gas boilers are equipped with various automation systems. Some of them are based on electronic modules, while others are tied to mechanical control. Both have their own merits and advantages, but you need to understand that non-volatile boilers can work in heating systems of private houses without electrification. And if you use bottled gas, you can do without a gas main. Electronically controlled models will require access to electrical power.

Harness

The winners here are double-circuit models, which are already equipped with all the necessary piping - these are expansion tanks, circulation pumps and security systems. If there is no harness, you will have to purchase it and install it separately, and this will take up additional space. But external piping has an advantage - it is easier to repair and maintain, since it does not require intervention in the internal structure of the boilers.

Control

Gas boilers for heating private houses are equipped with simple standard control panels. But to gain access to advanced functionality, external control modules are used - these are simple room thermostats, multifunctional control panels, as well as remote control modules with connection via GSM channel or via the Internet.

Other options

Heating equipment is constantly being improved, with more and more new functions appearing in it. Prices for gas boilers for heating a private home directly depend on the functionality specified by the developers. And the more options, the higher the price. For example, units with electronic ignition are more expensive than those with piezoelectric ignition. Approximate prices:

- Simple floor-standing single-circuit models 10 kW - 8-12 thousand rubles;

- Low-power double-circuit wall-mounted samples - from 17 thousand rubles;

- Double-circuit medium power, 20-22 kW - from 26 thousand rubles;

- Double-circuit floor-standing non-volatile, 20 kW - from 15-19 thousand rubles.

Additional options and technologies used in the equipment have a separate impact on the price.

Boiler power calculation

When choosing a gas boiler for a private home, you should pay attention to the power of the equipment. It is generally accepted that for heating 10 square meters. m of living space in the Russian climate requires 1 kW of thermal energy. In the northern and Far Eastern regions it rises to 1.2-1.5 kW, and in the southern regions it drops from 0.8 kW. But even in the south it is customary to stick to the average in case of a cold winter.

Following the formula, we find that to heat a private house with an area of 200 square meters. m. we will need a gas boiler with a capacity of 20 kW. But we forgot about required stock– it is needed in case of heat losses and excessively cold winters. As a rule, the reserve is 10-20%. Based on this, the recommended power of equipment for heating private houses with an area of 200 square meters. m. is 24 kW.

Table for calculating the power of a gas heating boiler for a private house.

Heat losses are affected by:

- Window design;

- Availability of insulation of the attic (or heated second floor);

- Availability of insulated walls;

- Ratio of window area to floor area;

- The number of external walls in a particular room.

The average temperature during the coldest period in a given area is also taken into account.

The heating boiler will provide the home with heat without the need to connect to central communications, resulting in cost savings and the ability to adjust the level of air heating. This is why cottage owners often choose boilers as a means of heating. And for those who connect to central system and cannot at all, such a device becomes a real salvation. In this case, you can select equipment according to various parameters and defining characteristics in each specific case. So which boiler is best for a private home?

Types of heating boilers

A boiler is a device that produces heat by processing a certain type of fuel. Installation may be different sizes, shapes, power, can be installed in different ways, and can also be made of various materials. Of course, all these indicators affect the cost of the device - there are budget boilers that cost only a few thousand, and there are also very expensive models costing more than 100 thousand rubles. At the same time, the price range varies from minimum to maximum among boilers of different types. What types of heating boilers are there and by what criteria are they classified?

Table. Classification of heating boilers.

To make it easier to decide on the choice of boiler, let’s get acquainted with their main types in more detail.

Double-circuit and single-circuit

Did you know that a heating boiler can not only heat the coolant in heating circuit from pipes laid throughout the house? The installation may well provide housing with hot water without purchasing a water heating boiler. The fact is that the unit can have two circuits - in one of them the water is heated for the purpose of heating buildings, in the other - in order to come from the taps, the shower is warm. Hence the name - double-circuit. A single-circuit boiler is used only to heat the coolant for heating buildings.

Single-circuit gas boiler - diagram

Fuel varies

As we noted earlier, boilers can operate at different types fuel. And here you should choose an installation based on the cost of fuel in a particular place - in some places it is cheaper to connect to gas, and in others it is more profitable to use electricity or ordinary firewood. Also, in certain cases (for example, if connecting to a gas main is impossible), a certain type of fuel will be the only solution.

Gas boilers are rightfully considered the most economical, as they use natural or liquefied gas - one of the cheapest types of fuel. Moreover, the amount of heat released when burning this raw material is maximum compared to other types. A gas boiler is relatively environmentally friendly - emissions into the atmosphere contain a minimum of air pollutants.

On a note! Gas boilers last quite a long time - for example, devices with a steel heat exchanger work for about 30 years, and with cast iron parts - all 50.

Another advantage of such a boiler is that there is no need to make a fuel storage facility, because the installation is connected directly to the gas main and takes fuel from there. And a person will not have to particularly control the combustion process - everything in the boiler is automated.

But connecting a gas boiler is not so easy: first you need to coordinate everything with supervisory authorities, bring the gas pipeline to the house. And during installation, it is important to check the tightness of all connections and components to avoid leakage. At the same time, only those whose house can be connected to the gas main can use such a boiler.

Electric boiler

Boilers that run on electricity come in three types and differ from each other in their operating principles.

Heating elements new devices They have tubular heaters inside the structure, which provide heating of the coolant (water). Such installations are usually automated, have relatively small dimensions and are often wall-mounted. Their main drawback– scale formation on heating elements.

Eat devices operating on electrodes, there are no heating elements inside them anymore. The water is heated by a conductive electrode. Such devices are inexpensive, and their sizes are also modest. Their main disadvantages are the inability to use antifreeze as a coolant, the need for control, and regular replacement of electrodes.

Electric boiler, can also be inductive, where the basis of operation is the so-called electromagnetic induction. By appearance such a device resembles a conventional transformer, which is located inside a welded housing. The induction coil does not come into contact with water, but during operation of the device, its core heats up and the resulting heat is transferred to the liquid that circulates around. The efficiency of the device is very high, as are its dimensions.

Attention! Electric boilers are not suitable for use in areas where there are frequent power failures. If the power goes out frequently, then either another type of installation or the construction of a generator is necessary.

In general, electric boilers are environmentally friendly, cheap, operate quietly, and are easy to use - they do not require much attention. There is also no need to install a chimney. But they spend quite a lot of electricity.

Solid fuel boiler

- This is the simplest option for heating equipment. In essence, this is an ordinary stove with a firebox and coolant. Fuel, which can be coal, firewood, sawdust, shavings, peat, fuel pellets, is placed in the combustion chamber, ignited by a burner and, when burned, heats the coolant and the water contained in it.

To install such a boiler in a house, you will have to equip a chimney, and also be prepared for the fact that the installation will have to be regularly cleaned of ash and soot. Without cleaning, the device will begin to give off heat worse, and in the future it will completely fail.

Solid fuel boilers can be both classic and long burning(pyrolysis, smoldering type). The first ones have the lowest efficiency and have a spacious firebox, where fuel is placed for combustion. Moreover, this process does not occur without human participation. These are the simplest in design and the cheapest installations, they are independent of electricity in the house, and are not capricious in relation to the quality of fuel.

Long-term combustion installations include pyrolysis and smoldering types. The first are based on the process of thermal decomposition of organic substances, that is, fuel due to high temperatures turns into coke and pyrolysis gas, which enters the next combustion chamber and is burned there - a double release of thermal energy occurs. The efficiency of such boilers is high, and fuel consumption is minimal. Often such installations are automated.

Boilers operating on the principle of smoldering provide combustion like a candle - that is, from top to bottom, and the entire device is enclosed in water jacket. The combustion chamber has big sizes, but combustion occurs slowly, so you will not often have to replenish fuel reserves.

Attention! Both types of long-burning installations are very demanding on fuel quality.

Liquid fuel boilers

Typically, liquid fuel installations are used in private homes or small industries. Quite economical, since, for example, diesel fuel It is quite cheap and has low consumption. Such installations are not afraid of power outages, since most often they are energy independent, and therefore are excellent for arranging an autonomous heating system. This is the most expensive type of heating boilers, which are nevertheless characterized by high efficiency (up to 94%), minimum quantity harmful substances in emissions, the possibility of automation, ease of maintenance. But the installation of such equipment should only be done in a separate room with good ventilation, and for fuel reserves it will be necessary to install fairly large containers made of metal or plastic.

Combination boilers

Such devices can be safely called universal, since they can operate on different types of fuel. For example, these could be installations that have two burners - one for fuel, the other for gas. The burner can also be universal. The equipment may have a combustion chamber designed to solid fuel, but at the same time there is the possibility of installing a mounted burner that will operate on both gas and liquid or solid fuel.

Attention! Since such boilers are technically more complex, the likelihood of breakdown is usually higher. Repairing them will be quite expensive, and a new similar device will cost even more.

The undeniable advantage of such boilers is their versatility. But they are quite bulky.

Material

If we consider boilers from the point of view of quality and materials, we distinguish cast iron and steel installations. The first ones are reliable, durable, hold heat well, but take a long time to heat up. Cast iron boilers almost never burn out, as they have thick walls. But this alloy is susceptible to strong impacts and can easily crack beyond repair. Because of this, sudden temperature changes should not be allowed. And cast iron boilers are very expensive.

Steel boiler – more a budget option. It is not afraid of impacts, it is not so heavy, but its service life is shorter - after all, steel is steel, no matter how good it is. Such boilers are afraid of rust and can burn out. Service life is short - only about 15 years.

Choosing a boiler for heating a house

How can you choose a truly suitable boiler for heating a private home among such a variety of types? In fact, the secret is simple - you need to determine exactly why the boiler is being purchased and how much money the home owner has.

Step 1. The first step is to decide for what purpose the boiler is being purchased - just to heat the house? Maybe it makes sense to take a double-circuit heater that will also heat the water? Here, a lot depends on the number of people living in the house and the required volume of hot water. If it is consumed in too large volumes, then it would be optimal to buy a boiler and a single-circuit boiler separately. But in a house where the hot water supply will not be so intense, it is more economical and logical to install a double-circuit.

Step 2. Now you need to decide which type of fuel is cheapest to buy. Here, a lot depends on the region - somewhere wood is cheaper, somewhere it’s easier to install an electric boiler. But in any case, if a gas main is connected to the house, the choice should be made in favor of a gas boiler.

Step 3. Cast iron or steel? Home owners can choose according to their wishes and the thickness of their wallet. Of course, steel is easier to buy, but cast iron is better in terms of heat transfer. However, now boilers of the second type appear on the market less and less often. Therefore, it makes sense to still choose a steel boiler, but from high-quality metal.

Step 4. The noise level should also be assessed, as well as the possibility of installing a chimney in the house. Installation requirements vary for all types of boilers, and the installation capabilities of a particular type must be taken into account objectively.

Step 5. It is important to calculate the boiler power, which is necessary to fully heat a residential building, before purchasing. On average, for normal heating you need about 1 kW per 1 m2. But it is important to take into account the height of the ceilings, the size and number of windows, doorways and other holes. The need to heat water for domestic hot water in the case of a double-circuit boiler is also necessarily taken into account.

Calculator for calculating the required power of a gas boiler