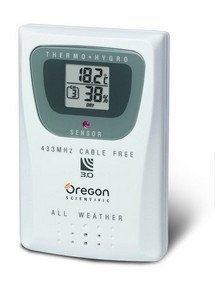

Boiler temperature gauge. Room temperature sensor for gas boiler

Outdoor temperature sensor for gas boiler- a device that allows you to automatically adjust the temperature of the coolant at the supply, depending on the air temperature outside.

Purpose and device of the temperature sensor

At the manufacturing plant, the automation of the gas boiler is configured to function at the most low temperatures outside air, but the temperature outside can change daily. You have to constantly adjust the work heating equipment. In order not to perform this process manually, the outdoor temperature sensor of the boiler is connected.

The temperature sensor allows you to adjust the heating of the coolant depending on the air temperature outside. Thanks to this, the boiler will work intermittently, and not constantly. This mode of operation will lead to gas savings, there will be a reduction in heating costs.

In most cases, the device has simple design. It includes:

- The sensor itself

- Terminals for clamping electrical cable;

- Cable box;

- All these parts are housed in a plastic case.

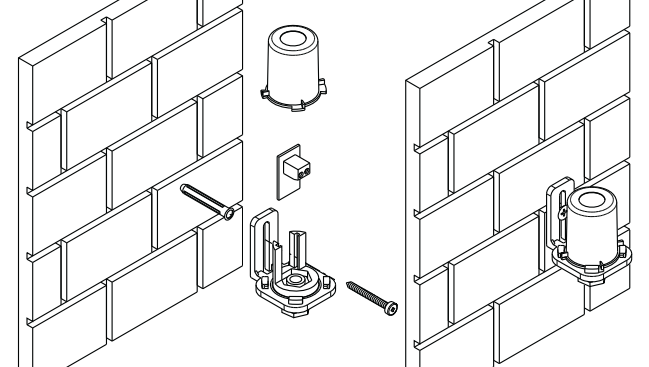

Temperature sensor installation

Installation of the outdoor temperature sensor for the boiler is carried out on the wall of the building from the street side. During installation, the following requirements must be met:

- Direct contact with the temperature sensor should be avoided. sun rays. Installation should be carried out on a wall facing north or northeast;

- It is not recommended to install on surfaces affected by mold or places where high humidity is present;

- It is forbidden to install the outdoor air temperature sensor on a metal surface, because metal structures are characterized by low thermal insulation;

- The operation of the device should not be affected by extraneous factors. Do not install it near a chimney, vent, door or other potential heat sources that may increase the temperature of the air around the appliance;

- If the installation is carried out on the wall of a building, not more than 3 floors high, then the installation should be carried out at the level of 2/3 of its height. If the house is higher, work is carried out between the second and third floors. For installation, it is recommended to choose a flat surface, and to fix the device with anchor bolts.

Mounting the temperature sensor on the wall

In order to gain access to the mounting holes and the terminal block, it is necessary to unscrew the protective plastic cover. After the place where the temperature sensor will be placed is determined, the centers of the mounting holes are marked. Next, the nut designed to seal the cable is unscrewed. After that, two wires are connected to the sensor. At the final stage, the sealing nut is tightened and the housing cover is closed.

Connecting the outdoor temperature sensor

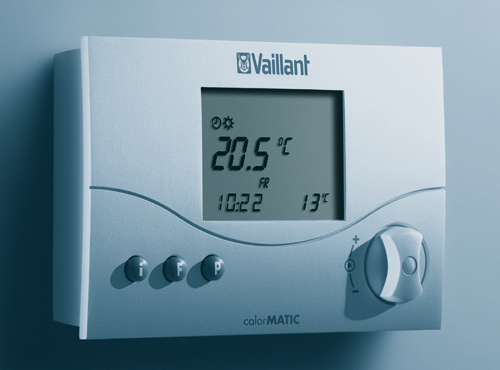

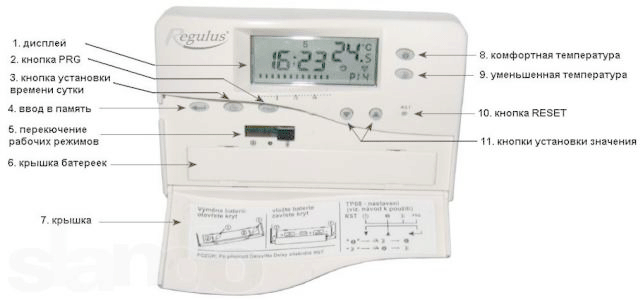

Turn the knob - we get the result, the temperature will be corrected by the thermostat

A room thermostat for a gas boiler is a new approach to space heating and hot water supply. This equipment, which is also called a room temperature sensor, allows you to control the operation of the gas burner in the most convenient format. In addition, the room thermostat for the boiler makes it possible to reduce the amount of fuel consumed by the system due to the choice optimal mode unit operation. Another plus of the temperature sensor is the extension of the life of the boiler.

All these advantages give rise to a serious demand for thermostats, which are gaining momentum in popularity every year.

What is a thermostat for?

If you have a gas-fired hot water and heating boiler installed in your apartment or house, you probably know that its work has to be adjusted from time to time. This is done by changing the temperature of the coolant in the system manually. If it gets cooler outside, you need to re-adjust the operating mode of the gas boiler so that the temperature in the room is as comfortable as possible.

The problem is that such reconfigurations must be carried out throughout the entire heating season so that the room is not too hot or too cold.

In order to maintain comfortable conditions in an apartment or house, gas burner equipment has to operate in a constant on and off mode. On average, the burner starts every 7-10 minutes. Of course, with such work, the equipment wears out quickly enough. Under special stress circulation pump, which operates continuously throughout the heating season. Naturally, this significantly increases the risk of its failure.

If you have a double-circuit boiler installed, then with the above operation mode, the monthly electricity consumption can be about 60 kW per month, with a rated equipment power of 24 kW.

Obviously, in this case, the gas boiler can hardly be called economical and convenient heating equipment. In addition, the durability of equipment when operating in such an aggressive mode is also in doubt.

At the same time, the installation of a modern temperature controller can make the work of equipment much more efficient. The room thermostat for a gas boiler is a device that regulates the operation of the unit, focusing on the temperature in the room. But it is this indicator that is the most indicative in terms of comfort in an apartment or house. The user does not care about the temperature of the coolant in the system. Much temperature is more important air in a specific room, and it is on this indicator that the thermostat is guided, turning the equipment on or off at the right time.

What is the principle of operation of a thermostat?

The wireless room thermostat for the boiler has a simple operating principle. The user only needs to set the appropriate temperature in the room, and the equipment itself will control the operation of the gas burner equipment. The boiler will only work if the air temperature in the house or apartment is below the specified one.

Thermostats on the market household appliances, have a different response threshold. There are models that are able to instantly respond to a quarter-degree drop in temperature. However, most thermostats have a sensitivity of one degree.

In this case, the thermostat turns off the equipment only if the temperature in the room reaches a level slightly higher than that indicated by the user. Remarkably, the sensor turns off not only the burner, but also the circulation pump, thereby saving its working life.

Savings start with the purchase of a thermostat

Since the air in the house does not cool as quickly as the coolant in the system, the number of boiler on and off cycles is reduced by several tens of times after the sensor is installed. Without a doubt, such work of equipment significantly extends the life of its operation, and also contributes to saving electricity and fuel. It's also very convenient because you don't have to manually adjust the boiler every time the house gets warmer or colder. It is enough once to set the desired comfortable temperature, and it will be maintained indoors continuously.

In most cases, when the heat in the house or apartment will be provided by other factors, the boiler will be turned off. For example, a room can be additionally heated if there is an increase in the number of people in it, or when the sun heats it from the outside. If your apartment is located between other apartments, it makes sense to install a sensor, because in part your home will be heated due to the high temperature in neighboring apartments.

![]()

Speaking of savings, it is worth noting that heating equipment that is not equipped with a thermostat consumes about 30% of additional energy. Such overspending is instantly reflected in the family budget.

An alternative “bonus” that the owner of a boiler with a room sensor receives is a much more gentle mode of operation of equipment without additional wear. The equipment will serve you much longer if you equip it with a thermostat.

Thus, it is not difficult to draw a conclusion about the advisability of buying a wireless room thermostat for the boiler.

If you decide to purchase a room temperature sensor for your boiler, pay attention to the tips below:

- Try to choose a thermostat made by the same company that made your boiler. This will make the installation and aggregation of equipment much easier. Naturally, this recommendation is not required, because experienced master will be able to mount any thermostat. The only question is the complexity of the work and its cost. In addition, the difference in trademarks may lead to additional inconvenience in the process of use.

- When buying a thermostat, be guided by the area of \u200b\u200bthe room and the temperature that you want to maintain in it.

- To reduce heat loss, it will not be superfluous to provide additional thermal insulation of an apartment or house before buying a sensor. Naturally, such a decision will positively affect the economy.

- If you do not want to spend a large amount immediately on an expensive thermostat, buy a mechanical thermostat that will need to be adjusted once a day. So you will understand how much easier such a sensor makes your life and, perhaps, you will purchase an expensive model, having experience in using simpler devices.

Today, when most owners of private houses and a huge percentage of those living in apartments prefer autonomous heating and hot water supply, the issue of saving resources is especially acute. Gas and electricity are steadily and steadily rising in price, which forces owners of heating equipment to look for new loopholes to save family budget. That is why temperature sensors (thermostats) for boilers can be a profitable investment. Moreover, such equipment pays off quite quickly, because it allows you to reduce resource consumption by up to 30%.

Today, when all of Europe is following the path of maximum savings and effective use electricity and gas, time for Russian buyers to think about reducing the cost of creating comfort in their homes. Modern temperature sensors, the choice of which is surprisingly rich today, will help our compatriots in this. Nowadays, it is possible to buy equipment that will suit you both in terms of price and functionality.

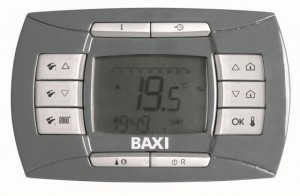

We study the room thermostat for the Baxi gas boiler

Baxi boilers are an excellent choice for autonomous heating systems. They are distinguished by increased comfort, a variety of automation and ease of use. Any additional equipment can be connected to the boiler. An example is programmers, or room thermostats for Baxi gas boilers.

Advantages of Baxi boilers

Main 24 Fi 24 kW

The advantages of Baxi gas boilers are obvious, and the possibilities of such units are multifaceted. We list only the main advantages of such boiler equipment:

- Connectivity additional elements, sensors and automation systems.

- The ability to automatically change the temperature regimes depending on the temperature delta in the street and at home.

- Economy of operation.

- "Smart" self-diagnostic systems.

- The possibility of using the unit not only in traditional heating networks, but also in the "warm floor" system.

Additional accessories

Note! Most models are equipped as standard with built-in electronics, control systems and various sensors. Installing optional accessories makes operation easier, more convenient and more efficient.

Additional accessories open whole line equipment management options:

- Temperature control by time of day and season.

- Setting the temperature in different rooms.

- Work in economy mode.

All this reduces gas consumption, which means it makes the system energy efficient and its operation economical. Paradoxically, most consumers refuse to install additional equipment for reasons of economy. Of course, the installation of these devices will increase the cost of the system. But on the other hand, it will save on heating bills.

The installation of additional devices pays off in the first two heating season. So gas accessories Baxi boilers- it's not only extra comfort but also significant fuel savings.

Variety of accessories

accessories and additional equipment there are a lot of Baxi boilers on the market. We list the main ones:

- Digital timer. The device allows you to program the work engineering networks for a certain period. When using it, the boiler will turn on / off at the time specified by the consumer. You can use this device not only for programming heating, but also for boilers.

- Room thermostat, or thermostat. This device maintains the set temperature and allows you to control the microclimate. The boiler equipped with a programmer will work in automatic mode. In this case, no intervention on the part of the consumer in the operation of the unit is required.

- Outdoor temperature sensor. To maintain heat in the house, it is necessary to take into account the temperature of the street air. The power with which the boiler must operate directly depends on the delta (difference) of room and street temperatures. The outdoor temperature sensor allows you to maintain a constant mode, no matter what the weather is outside the window.

- Room temperature sensor. It is recommended to install it together with the above device. Both devices, working in pairs, guarantee the so-called self-adaptation of the boiler.

- Digital control panel. This is a real highlight. You can install it in convenient location. With its help, not only control, but also system diagnostics takes place. This device can be used with or without a programmer.

These are not all accessories that can be connected to Baxi indoor gas boilers. In more detail, you should dwell on the most common device - a thermostat, or temperature controller.

Why do you need a thermostat?

In fact, the thermostat is a device that allows you to regulate the temperature in the room in automatic mode. It can be argued that it is easy to regulate the operating modes of the boiler without automation, that is, manually. At the same time, the thermostat becomes an unnecessary luxury, entailing extra costs funds. Consider the pros and cons of installing such accessories.

During the operation of gas boilers, the microclimate in the premises is regulated by changing the temperature of the coolant. When the set value is reached, the boiler turns off, and when it decreases, it turns on again. When changing outside temperatures, it is necessary to change the parameters of the heating system, and this must be done manually. As a result of interference with the operation of boiler equipment, they are required throughout the entire heating season.

The time and attention taken by the boiler when manually adjusting its operation is not the most important issues. In this mode, frequent starts / shutdowns of the boiler occur, which is not the most in the best way affects its performance, and the reliability of the system as a whole. There is one more problem. When the boiler is in constant on / off mode, the circulation pump continues to function. Being an energy consumer, it increases the cost of electricity, which increases financial expenses for heating. Not to mention negative impact for the operation of the system.

As you can see, manual control for a high-tech gas boiler is not the most the best option. Now consider what the thermostat can change. The device has room temperature sensors that monitor the temperature not of the water in the system, but of the air in the premises. As a result, the boiler is turned on / off when there is a deviation from the set temperature regime, and not when the water heating decreases.

The frequency of starts/shutdowns is significantly reduced. When programming the device, you can set the optimal threshold for triggering such a sensor. In addition, you can set the delay time for turning on or off the boiler when the sensors are triggered. This will minimize the likelihood of starting the heater in case of a short-term decrease in temperature, for example, as a result of a draft.

Model TAM011MI Seitron

As practice shows, installing a programmer saves 25-30% of energy. The device does not allow excessive fuel consumption. When the boiler is turned off, the circulation pump is automatically turned off, which saves energy. All this speaks in favor of installing room thermostats.

The payback of such accessories is beyond doubt. On the market are various models thermostats, differing not only in technical parameters, but also in price. Finding the right accessory is not difficult. Examples include TAM0 11MI, Menred RTC 70, Raychem TE Basic, DEVIreg Touch, Nest, domestic MCS 300, etc. temperature controllers.

Central thermostat

This type of programmer is installed in the house and connected to the heater either by wires or via wireless networks. The latter are more expensive, but more convenient and efficient.

The main advantage of wireless thermostats is the ability to install them anywhere. At the same time, they do not violate the interior, and their installation does not require any complex fixtures or destruction. building structures. The case is fastened with self-tapping screws, after which all the necessary electronics are connected, and the necessary parameters are set. This device can be operated remotely. Its operation is allowed not only with gas, but also with solid fuel boilers.

Installation rules

Installation of central thermostats is simple. But it is necessary to adhere to several rules in order not to violate the efficiency of the system in the future:

- The regulator is mounted in such a way as to ensure free air flow.

- Nearby there should be no household electrical appliances, lamps, touch switches, additional heaters, etc.

- The thermostat must be freely accessible.

Additional options

The main function of thermostats is temperature control. For greater efficiency, the devices have additional options:

- The ability to turn off the heating for several hours, for example, in the long-term absence of people in the house.

- Possibility of temporary change of all programmed modes of operation.

- The ability to change the temperature regime on certain days.

The benefits of installing a thermostat are obvious. The payback of devices is also not in doubt. Nevertheless, the desire to save on the installation of such useful device still remains strong. This often encourages homemade "homemade" to do everything with their own hands. And not just to install the device yourself, but also to assemble it from improvised materials.

Theoretically, it is possible to make a thermostat with your own hands. This will require a thermistor that reduces resistance when heated. Then another resistor is connected to the network, with the help of which temperature programming will be carried out. The 2I-NOT element will operate in inverter mode, and voltage will be supplied to it. A capacitor is connected to it and to the trigger. To control the relay, the galvanic isolation on the triac is enhanced. The device can be made both on a mole rat and on a printed circuit board.

Using such a simple circuit, you can assemble a thermostat for almost any boiler. But is it worth interfering with the operation of high-tech equipment? It's up to the owner of the house to decide. Experts do not advise experimenting with homemade devices, especially since on the market you can pick up accessories for any boiler.

In order not to make a mistake in choosing a programmer and purchase suitable model enough to adhere simple tips specialists:

- It is desirable that the boiler and its accessories are made by the same manufacturer.

- Powerful models of heating equipment can be operated with any version of programmers.

- Before buying, it is worth calculating the necessary technical specifications Otherwise, equipment downtime is likely.

- If it is necessary to install a device of a high power class, it may be necessary to change the wiring, so it is better to consult a specialist.

Any doubts left? You can always buy a cheap model with a minimum set of features and options. Its operation will clearly show how expedient the installation of expensive additional accessories is.

Conclusion

Additional accessories for Baxi gas boilers are not a luxury, but an opportunity to make the heating system energy efficient in the full sense of the word. Installing just one room thermostat allows you to reduce heating costs by about 25-30%.

Automatic control of a gas boiler using a room thermostat

A room thermostat is a device that allows you to regulate the operation of your heating unit in the form that is most convenient for you. It will help to reduce the cost of gas and electricity, increase the life of the boiler and ensure a constant temperature in the room. The article contains many useful tips on the choice of thermostat, its installation, connection and further use.

Principle of operation

The gas boiler operates cyclically, turning on when the temperature of the coolant (water) drops to a certain value that you set manually. Then the pump starts to work.

The lack of automation leads to the need to adjust the parameters heating system throughout the cold season. But even manual adjustment does not guarantee that on especially cold days an apartment or house will not freeze, and on a warm sunny day it will not turn into a sauna.

This is what thermostats are for.

They are equipped with an air temperature sensor of the heated room. You yourself can set the desired temperature on the thermostat - it will automatically turn on the gas boiler and pump at the right time, and only for the required period of time.

Unlike a gas boiler, for which the most important parameter is the temperature of the coolant, the temperature of the air in the room is important for the thermostat.

You set the lowest possible temperature once. at which you are comfortable being in a room without heating. As soon as the air temperature drops below this value by 0.25-1 degrees (the step depends on the model of the device), the thermostat automatically starts the boiler and the pump.

If the temperature exceeds the threshold you set by the same 0.25-1 degrees, the thermostat will automatically turn off the heating system.

Three main advantages of thermostats

Automation for a gas boiler

The air in the room does not cool as quickly as the coolant in the circuit, so the number of starts of the heating unit is reduced many times, which favorably affects its service life and your financial condition.

As stated above:

- they increase the level of comfort - the temperature in the room will be stable in any weather, only the frequency of switching on the heating system will change;

- eliminate the need for frequent adjustment of the boiler parameters;

- significantly reduce heating costs.

In normal mode, the boiler works on average once every 10 minutes and heats the water for 1-2 minutes, while the pump runs constantly. In the presence of automation, the boiler will turn on much less frequently, and the pump will only work at times of need, pumping the heated coolant along the circuit.

According to some reports, savings can be up to 25-30%. which makes the device very efficient and pays for itself quickly.

Types of room thermostats

Automation for adjusting the operation of the boiler can be divided into:

- Wired– communication of the boiler with the controller is provided by a wired connection (requires additional installation).

- Wireless– the whole working process is controlled by radio signal.

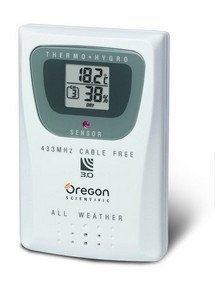

The wireless thermostat kit includes two blocks, one of which is installed near the boiler and connected to its terminals, and the second is installed in the room from which the heating system is supposed to be controlled.

Both blocks are connected to each other by radio. For ease of use, the control unit is equipped with a mini-keyboard and a liquid crystal display.

According to the functions performed, room thermostats are divided into:

- Simple– can only support in advance set temperature in room.

- Programmable They are also called programmers. They have a rich set of functions: you can change a number of boiler parameters remotely, adjust temperature conditions"day" and "night", program the heating system according to the days of the week.

- With built-in hydrostat function- they allow you to monitor the level of humidity in any room where there is a need to control the microclimate. Have the built-in mode of decrease and increase of humidity.

Popular models and manufacturers

The most popular in the Russian market are thermal sensors of such brands as Siemens, IMIT, Thermolink and Baxi.

The range of manufacturers is very wide and includes both entry-level models and serious thermostats for multi-circuit boilers with a wide range of additional functions.

Consider several popular models and compare their characteristics.

To reduce the cost of fuel and electricity, it is worth adopting several important points:

- Lower the thermostat temperature if you are going to leave the room for a long time.

- It makes sense to set the temperature lower by 3-4 degrees at night. The first member of the family to rise in the morning can increase the temperature and warm the room. Automate this process if you have purchased a programmable thermostat.

- Keep your device in working order. Change batteries without waiting for the device to fail.

- Make sure that in rooms for the elderly and the disabled, the temperature does not fall below 16 degrees.

- Recommended temperature.

- 20 degrees for common areas;

- 18 degrees for a children's room;

- 16-19 degrees at night;

The choice of a gas boiler and a thermostat from one well-established manufacturer will avoid many problems associated with the operation of the heating system in the future.

How to use backup power for a gas boiler, protect the heat supply system from restarts and the possibility of overheating of the coolant.

How to use backup power for a gas boiler, protect the heat supply system from restarts and the possibility of overheating of the coolant.

5 comments

Description sucks. Chewed snot and everything. Just like all sites. You tell stories about wonderful thermostats. Anyhow shove goods and cash in. And you wrote where to poke two wires into the boiler coming from the thermostat? We close them, open them, but what's the point? Gas boilers are not designed for such adjustment. Don't bullshit people and don't waste time. Because of people like you, I spent 12 hours looking for information on connecting. Do not e ... those people's brains. These regulators can only control el. boilers.

My friend. All genius is in simplicity! The sensor is installed on the circuit after the voltage stabilizer. The boiler has a built-in thermostat to the maximum, and the desired temperature on the sensor. And you will be happy.)))

Anton. In 1_x you need to think with your head at the beginning. Last year I installed controllers in production. Savings from 12.5 thousand cubic meters to 10 thousand (2500 cubic meters per month) with the same quality of heating.

This year I installed it at home, from 6 to 16.00 the temperature is maintained at 17 degrees, by 17.00, when I arrive at 21.75 degrees, 0.25 degrees (delta), after heating the batteries - the temperature in the room is 22.5.

As for connecting to a gas boiler - in most gas boilers on the right (bottom) there is a jumper, but don’t go there yourself, you have companies in the city for installing gas boilers - they will connect and adjust the gas on the boiler.

Another 1 (+) of this chip - the gas boiler starts to work differently. The gas immediately turns on to full, as when heating water, and not hemorrhoids (by a third) and turns off at 60_70 degrees, to which you set the boiler, due to which you get additional savings gas.

January 30, 2015

To prevent overheating and high loads on boiler equipment install special devices. These are thermostats for gas boilers. In today's article, we will try to tell you in detail about this part, as well as consider its design and purpose.

What is it for?

During operation, the boiler heats the water in the system, after which it moves through the radiators. And if the pressure level of the liquid or its temperature exceeds the norm, after a while an accident will occur in the system. So, in order for the system not to be subjected to frequent overheating, it is understaffed with thermostats. Often, several parts are used in a room. Temperature controllers for gas boilers are mounted at their outlet, as well as on each battery. This is necessary in order to control the heating temperature of the liquid.

It is worth noting that gas equipment constitutes a high-risk item. At improper operation burners cannot burn fuel properly, causing gas to fill the combustion chamber, increasing the risk of explosions and fires. As a result, the boiler overheats, and the water in the system is converted into steam (in this case, the pressure on the pipes increases significantly). Of course, modern boilers are able to turn off during significant overheating, since special sensors are provided in their design. But, as practice has shown, when the temperature rises too quickly and somewhere far from heating element they are not able to respond to these changes in time. As a result, the system overheats. Under such circumstances, only a local fuse helps, that is, a thermostat for a gas boiler. It gives a signal in a matter of seconds, so you don't have to worry about the risk of overheating the system.

Design and principle of operation

What are these elements made of? The thermostat (including for the AOGV gas boiler) consists of several strips of metal. The latter have different coefficients of linear expansion. These strips work as an electrical switch contact in the heating circuit. Due to the difference in the coefficient of the two metals, they are deformed, after which the chain is broken. The steel strips are in contact with the valve closing mechanism. When the temperature rises above the nominal value, the contact goes down. Further, at the level of the valve, access to water, steam and gas is blocked. Thus, the operation of the boiler stops, and the radiators cool down naturally, exchanging heat with the air in the room.

What happens next? After the steam / water temperature drops to normal, the thermostat will open the valves and restart the boiler. It should be noted that frequent overheating of the system may damage the design of valves and fuses. Therefore, after each such situation, it is necessary to check the integrity of important mechanisms.

As you can see remote thermostat for a gas boiler has the same principle of operation as a car thermostat - as soon as the temperature rises, a special valve opens in the system, and the liquid is pumped through big circle. True, in the case of a car, the sensor is not able to turn off the internal combustion engine.

Varieties

When buying this element, it is important to take into account a number of parameters and characteristics of the particular heating system that is used in your room. Below we will consider which thermostats for gas boilers exist and how each of these types is characterized.

This type of thermostat works exclusively with free air flow. That is, there should not be any elements blocking air circulation near it. It can be a curtain, a closet or other furniture located next to a heat source (radiator). This is the most popular thermostat for a gas boiler (Beretta9raquo; including). These devices can also be used for heated towel rails.

The room thermostat is a device that regulates the operation of the heating boiler depending on the current room temperature. That is, the sensor does not work taking into account the heating of water in the tubes. In this way:

- The heater (in our case it is a gas boiler) in the absence of an installed thermostat turns on and off depending on the water temperature.

- A heater with a room thermostat operates depending on the heating of the air in the room.

That is why thermostats for gas boilers are not recommended to be covered with any decorative covers, force furniture and other things. By the way, this type of device is equipped with a convenient digital display and can be programmed at the touch of a button.

This abbreviation hides special kind elements - thermostatic valves. These devices do not directly control the boiler. By their structure, they only reduce the flow of water through the battery, and only if the temperature rises above normal. Most often, expansion valves are mounted in places where the level of water pressure is the lowest. Thermostatic valves of this type, as well as room valves, are not recommended to be installed under covers and other design devices. The fact is that if there is a violation of the air circulation in the room, the device will not measure the exact level of heating of the system, respectively, it will be useless in your home.

Remote controllers

Experts recommend installing zone remote controllers together with expansion valves. These devices will help control the air temperature in a room or in a separate area of \u200b\u200bthe room using infrared rays. As soon as the system begins to boil, the sensors will send a signal to the boiler or regulator valve, after which the heater will stop working.

Cylinder thermostat

This type of device is recommended to be installed if a 2-circuit boiler is installed in the room. At the outlet of the system, the water reaches a very high temperatures(more than 80 degrees), and in order to prevent pipe deformation and leakage, such liquid regulators are mounted before passing to the battery. It is worth noting that the cylinder thermostat is fully programmable. This means that the owner can independently set the temperature at which the boiler will turn off for a certain time. Most of these regulators are adjusted in the range of 60 degrees Celsius.

“Smart9raquo; thermostats for gas boilers

These devices, in their principle of operation, are very similar to direct-acting water regulators. They also monitor the state of the system from the command unit and, if necessary, turn off the boiler until the liquid temperature stabilizes. In addition, “smart9raquo; thermostats are able to turn off boiler equipment, also controlling the amount of pumped in the pipes hot water. In the event of an emergency, the electronics react quickly and close the valves in the system. This type of device can be both digital and electronic. The latter consist of several components - a display, a board and contacts.

How to install correctly?

Judging by the reviews, it is quite possible to install a programmable thermostat for a gas boiler indoors with your own hands. And it does not matter whether the device is mounted on metal, cast iron or aluminum batteries- the whole process is similar and requires a minimum of tools.

So, how to properly turn on the regulator in the heating system? The first step is to drain the water from the pipes. This is how we defuse the system central heating. Most often, this requires opening one valve located at the water inlet to the system. Next, the pipes are purged, and the adapter is unscrewed. How to do it? In order to disable the adapter, you need to perform several manipulations.

- Put a lot of pieces of rags. It can be rags or towels. It is important that they all consist of terry or cotton - this way more water will be absorbed into them. Alternatively, you can use an ordinary sheet of paper or cardboard.

- Press the old valve body with an adjustable wrench. The second wrench is needed to loosen the nuts that hold the valve to the pipe and adapter. Then we boldly remove the mechanism from the radiator. In some cases, it is necessary to use a battery valve that is built into the radiator.

On the next step a new device is installed. Before installation, it is important to thoroughly clean internal thread. A piece of clean cloth is best for this. After the thread is wrapped with a special locking tape (white stripe) clockwise. It is recommended to smooth it after each new turn. Next, the screw element is connected to the corner gaskets.

During installation, the blind nut must be replaced, as well as the old steel collar made of copper pipe. If the latter does not slip off, carefully and accurately cut out its parts and tear them apart with a compact screwdriver.

After the thermostat for the gas boiler is installed (you can see a photo of the finished element in working condition below), you need to tighten the nut, which is located between the adapter and the valve. The latter should be kept adjustable wrench. It is important not to overtighten the threads, otherwise the system may depressurize.

Next is the installation of a spare protection system. To do this, the pipes are filled with water again. After the system is completely filled with fluid, check all connections for leaks. If the valve is in big room(for example, the living room), it is left completely open. In the case of a small room (kitchen or nursery), you need to close it halfway.

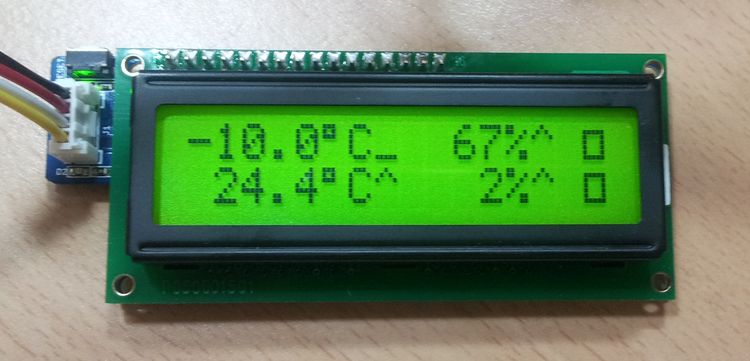

Temperature sensors are necessary to transmit information about the current state of the coolant and the current temperature in controlled rooms. The data from the sensors is sent to the controller, which processes the information received and generates a control signal to correct the operation of the heating boiler.

All temperature sensors for heating, which are used to monitor the current state of the circuit, are divided into 2 types. In principle, any of them will provide full control of the heating system, the difference is in the use of various design solutions and in the method of transmitting information.

All temperature sensors for heating, which are used to monitor the current state of the circuit, are divided into 2 types. In principle, any of them will provide full control of the heating system, the difference is in the use of various design solutions and in the method of transmitting information.

Information transfer methods are divided into the following types:

- wire sensors;

- wireless sensors.

Wired temperature sensors for heating, and this is clear from their name, transmit data to the controller through wires laid from the sensor to the boiler control unit. High-tech wireless sensors transmit information using a transmitter and receiver of radio waves. Approximately how a WiFi router works.

Thermal sensors according to the method of their placement are divided into the following types:

How many temperature sensors are needed for heating?

If only one room temperature sensor for a gas boiler is used for a conventional heating circuit, then with radiation collector circuit heating of such sensors can be several. In this case, the temperature control occurs for each room individually. The temperature sensor for heating located in each room sends information to the controller, which, through the control unit, regulates the independent supply of coolant from the collector to the desired room to maintain set temperature. You can read more about automation for boilers in our article.

If only one room temperature sensor for a gas boiler is used for a conventional heating circuit, then with radiation collector circuit heating of such sensors can be several. In this case, the temperature control occurs for each room individually. The temperature sensor for heating located in each room sends information to the controller, which, through the control unit, regulates the independent supply of coolant from the collector to the desired room to maintain set temperature. You can read more about automation for boilers in our article.

Visual temperature control

Thermal sensors are designed to control the temperature of the coolant, the temperature inside and outside the heated room various types. For visual control, most room thermostats are equipped with displays that show the current room temperature. The temperature measurement devices installed on the boilers also provide for the possibility of visual control.

Thermal sensors are designed to control the temperature of the coolant, the temperature inside and outside the heated room various types. For visual control, most room thermostats are equipped with displays that show the current room temperature. The temperature measurement devices installed on the boilers also provide for the possibility of visual control.

For heating systems, the following types of thermometers are used:

Gas boiler malfunctions associated with temperature sensors

The reasons that cause failure or unstable operation are many. In each case, you need to understand specifically.

The main malfunctions of gas boilers are:

The main malfunctions of gas boilers are:

- the boiler does not start;

- burner damping;

- the gas boiler does not gain temperature;

- the boiler does not turn off.

Can these malfunctions appear due to the failure of the temperature sensors? They can, and in the process of finding the causes of a failure, temperature sensors, their circuits, the transmitter and receiver for wireless systems should be checked first. The following options cannot be ruled out.

Can these malfunctions appear due to the failure of the temperature sensors? They can, and in the process of finding the causes of a failure, temperature sensors, their circuits, the transmitter and receiver for wireless systems should be checked first. The following options cannot be ruled out.

Security comfortable conditions living in modern country house unthinkable without a reliable and safe system in operation autonomous heating. The most important element The equipment of such systems is an individual heating boiler capable of maintaining a comfortable climate in the premises. The most widespread gas boilers, since natural gas in Russian conditions is still the cheapest fuel.

Comfortable climate in the house or apartment

Of course, it is possible to regulate the heat in apartments or houses manually, but it is much more convenient when the heating process requires almost no attention or is completely automated. For these purposes, autoregulators are used, which, using temperature sensors for gas boilers, independently maintain a given thermal regime.

In most designs of modern gas units, it is possible to connect various auxiliary devices (outdoor temperature sensors, timers, etc.) to an automatic control system (controller). Therefore, when installing individual heating it is necessary to choose the method of parameter control: additionally connected sensors for heating appliances, or thermostats built into them.

Why connect them?

The general purpose of temperature sensors is to control the degree of heating of the heating and air circuits, inside and outside the room. They transmit a signal to the thermostat to ensure the optimal mode of the combustion process and control heating. Depending on the purpose, location and method of signal transmission, heat indicators for gas heaters are divided into groups:

By appointment:

- air temperature sensors

- coolant heating sensors

By location:

- indoor

- outdoor

- invoices

- submersible

Signal transmission method:

- wired

- wireless

Room temperature meters

Are intended for measurement and control of a climate in heated objects. When the air temperature changes, the room sensor transmits information to the automated boiler control module, which reduces or increases the heating power of the heating circuit.

Thermostats can use remote temperature sensors for the boiler, built-in sensors, or both types together.

External meters

The heat balance, independent of external weather conditions, is maintained by means of an outdoor temperature sensor for boilers installed outside the building. In case of warming or cooling, the boiler's external sensor activates the weather-dependent program of the heat generator, which corrects the heating of the water supplied for heating according to a certain schedule. Heating of the heat carrier will change depending on changes of external air temperature. Thus, taking into account the actual external conditions improves comfort for the consumer and saves fuel.

In addition to a remote temperature sensor for the boiler, other elements for measuring temperature indicators are usually connected to the unit.

Wired and wireless

Depending on the method of data transmission to the control device, temperature sensors are divided into two types:

Wired. Communication with the controller is carried out using wires, through which information is transmitted.

Wireless. In such devices, data is transmitted to the control module via radio. Consists of two blocks: transmitting, installed in the controlled room, and receiving, installed on the boiler or next to it.

Coolant heating meters

Used to determine the temperature of the carrier in the heating circuits of gas boilers or boilers. Available in several types:

Overhead sensors. They are installed on the outer surface of the pipeline and fastened with a special clamp or tape.

Submersible water temperature sensors for the boiler are placed in special seats on pipelines and have direct contact with the coolant. Thermoelectric converters (resistance thermometers, thermocouples) calibrated for certain temperature ranges can be used as sensitive elements in them. These devices can be calibratable (with adjustable measurement limits) and non-calibratable, without display, with display, etc.

Summing up, I would like to note that the need to use temperature sensors for gas boilers is due to their successful use both to ensure comfortable living and to save thermal energy, and therefore to reduce material costs consumer.

Temperature sensors are accessories for the boiler heating system. The temperature sensor for heating allows you to quickly read information about the temperature of various elements of the heating system (boiler, boiler) and adjust its operation accordingly. The classification of sensors can be represented as follows:

- Air temperature indication.

- Indication of the temperature of the heating device.

- By location (indoor or outdoor, submersible or overhead).

- By the method of communication (wired, wireless).

Temperature sensors for heating

To buy a temperature sensor for a boiler, you need to have an idea of its functionality and compatibility with other elements of the heating system. Sensors are available for heating systems from manufacturers such as:

- Vaillant;

- Protherm;

- Baxi;

- Meibes;

- reflex.

Among them there are thermostats, universal wire sensors, outdoor air temperature sensor, water temperature sensor in the boiler, clamp-on sensors for heat exchangers and pipelines, etc.

External digital temperature sensors in Moscow

Our company can offer a digital temperature sensor for measuring the temperature in the external environment. These sensors, installed outside the room, allow the automation of the boilers to set different intensity of heating the room depending on the conditions. external environment. An external temperature sensor is provided by manufacturers such as Protherm, Vaillant, Baxi, and all devices are ultimately designed to reduce consumer heating costs as a result of more accurate temperature control.

Outside temperature sensors allow heating systems to realize the most economical way settings of its work - weather-dependent regulation. If the sensors are connected to the control unit via wires, then they carry out wired data transmission. Also popular is the wireless method of transmitting data from the sensor to the control device via a radio channel protected from interference. For example, the Baxi manufacturer in its boiler models uses a combination of the functions of a temperature sensor and a removable portable control panel in one device, which makes operation even more convenient. AT Protherm boilers and Vaillant all sensors necessary for control and safety of work are included in the equipment delivery set.

Buy an electronic temperature sensor for the boiler

The electronic temperature sensor for the boiler has a consignment note and a submersible version. The devices are designed to maintain the temperature of the coolant at a given level, so this type of sensor has a wide temperature range for regulation (within 90 degrees Celsius). They are able to independently perform the functionality of measuring the temperature of the boiler, or transmit data for further processing to the heating system control system.

Boiler temperature sensors can be used for seasonal winter/summer operation. They can also transmit temperature data at key points in the system to the controller for further analysis and diagnostics. In boiler models from manufacturers such as Vaillant (AtmoVit series), Protherm (Bear series), Baxi (Luna, Nuvola series), the manufacturer installs built-in electronic sensors boiler temperature.

When installing optional equipment for recording and controlling the temperature of heating systems, we recommend choosing sensors from the same manufacturer as the heater.

Prices for outdoor temperature sensors for air

The air temperature sensor, the price of which in our company allows you to optionally complete the heating equipment without restrictions, despite the narrow functionality (its purpose is to measure the air temperature and report the received data to the device controlling the heating system), is very important in the overall picture of the boiler. Installation of an air temperature sensor ensures adequate operation of the heating system and its efficiency.

The cost of the devices does not exceed three thousand rubles, while the benefits of operating the sensors are obvious. Temperature sensors available in stock and on order. Turning to the specialists of the Terem company, you will always receive competent advice on technical specifications devices, installation conditions, etc. All equipment is accompanied necessary documentation from the manufacturer.

Also in our catalog are such control devices for optimal performance heating equipment such as thermostats, control modules, relays and timers.

Read also...

- Education of the USSR: prerequisites, stages, significance When the USSR was created

- Education of the USSR: briefly about everything What led to the formation of the USSR

- Socialist-Revolutionary Party: who are they? Their goals and program. Political parties at the beginning of the 20th century Socialist-Revolutionaries party program table briefly

- Vitaprost rectal suppositories: how to use the drug correctly You can take Vitaprost without a doctor's prescription